Flexible Packaging Thickness Tester Desktop Thickness Testing For Plastic Film/Tube ISO 4593 Thickness Gauge

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Test Range | 0~2mm(Customization Available) | Resolution | 0.1 μm |

|---|---|---|---|

| Standard Measure Head | Hemispherical Type | Optional Measure Head (flat Foot) | 50 Mm² , 17.5±1 KPa (for Film)/200 Mm² , 50±1 KPa (for Paper) |

| Power | AC 110~220V |

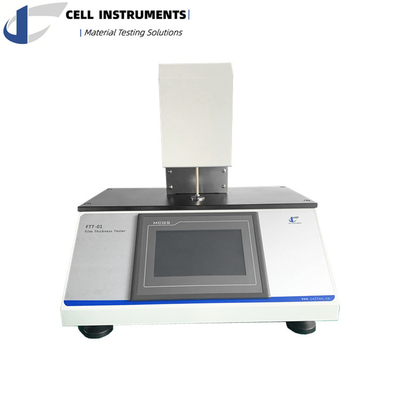

Flexible Packaging Thickness Tester Desktop Thickness Testing For Plastic Film/Tube ISO 4593 Thickness Gauge

![]()

Enhance your quality control processes with the FTT-01 Thickness Tester, a cutting-edge solution designed for precise and reliable measurement of material thickness. Ideal for industries such as packaging, food, medicine, and more, this desktop thickness testing instrument adheres to ISO 4593 standards, ensuring accuracy and compliance with international regulations.

Introduction of Plastic Film Thickness Tester

The FTT-01 Thickness Tester by Cell Instruments is your go-to solution for accurate measurement of plastic film thickness. This industrially stable unit, controlled by a Programmable Logic Controller (PLC) and operated via an intuitive Human-Machine Interface (HMI) touch screen, ensures both precision and ease of use.

Advantages of Plastic Film Thickness Tester

![]()

- PLC Control and HMI Touch Screen Operation: Enjoy industrial-level stability and user-friendly operation for efficient thickness measurement.

- Automatic Presser Foot Lifting: Streamline testing processes for consistent and accurate results.

- Real-time Display: Instantly analyze maximum, minimum, average, and standard deviation measurements for quality control.

- Test Result Storage and Micro Printing: Facilitate record-keeping and traceability with the capability to store test results and micro printing functionality.

- Optional RS232 Port and Software: Connect with optional software for enhanced data analysis and reporting capabilities.

- Sample Feeding Options: Choose between manual and automatic sample feeding to suit your testing requirements.

Why Choose FTT-01 Thickness Tester?

- Product Quality Assurance: Ensure consistent film thickness to prevent defects and maintain product integrity.

- Cost Control: Optimize material usage and reduce production costs.

- Regulatory Compliance: Meet industry standards, particularly ISO 4593, ensuring compliance with thickness requirements.

- Process Optimization: Identify and correct deviations or equipment issues to streamline manufacturing processes.

- Material Efficiency: Optimize thickness for efficient material use and waste reduction.

- Customer Satisfaction: Meet customer expectations for product dimensions and performance, fostering repeat business.

Main Parameter

| Test Range | 0~2mm(Customization available) |

| Resolution | 0.1 μm |

| Standard Measure Head | Hemispherical type |

| Optional Measure Head (flat foot) | 50 mm² , 17.5±1 KPa (for film) 200 mm² , 50±1 KPa (for paper) |

| Power | AC 110~220V |

Purpose of FTT-01 Thickness Tester

![]()

- Ensure product quality and consistency.

- Facilitate cost control through material optimization.

- Guarantee regulatory compliance in industries with strict standards.

- Enable process control and optimization.

- Enhance material efficiency and reduce waste.

- Meet customer expectations for specific product dimensions and performance characteristics.

Application

The FTT-01 Thickness Tester is suitable for measuring the thickness of various materials including plastic films, sheets, fabrics, textiles, membranes, paper, foil, and wafers.

Standards

Compliant with international standards such as ASTM D374-99, ASTM D1777, ISO 3034:2011, ISO 534-2011, and ISO 4593, ensuring accuracy and reliability in thickness measurements.

Technical Features

- Controlled by a PLC and operated through an HMI touch screen.

- Automatic presser foot lifting for convenience and consistency.

- Real-time display of key measurements.

- Test result storage and micro printing capabilities.

- Optional RS232 port with software compatibility.

- Manual and automatic sample feeding options available.

![]()