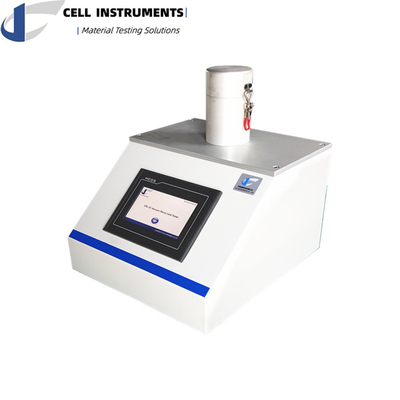

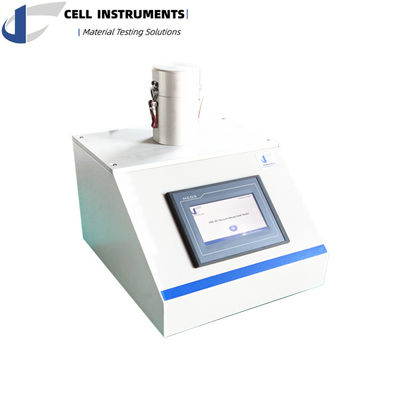

ASTM F2338 Micro Leak Tester High Precision Vacuum Decay Seal Strength Testing Equipment For Medical Packaging

| Test Range | 1Pa | Sensitivity | 1~3μm |

|---|---|---|---|

| Chamber Size | Made-On-Demand | Vacuum Pump | To Be Prepared By User |

| Power Supply | AC 110~220V 50Hz |

ASTM F2338 Micro Leak Tester High Precision Vacuum Decay Seal Strength Testing Equipment For Medical Packaging

![]()

Introduction to the ASTM F2338 Micro Leak Tester

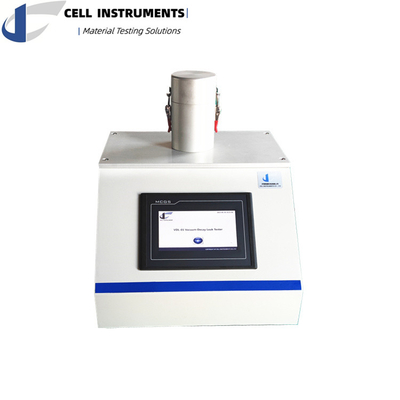

The ASTM F2338 Micro Leak Tester, model MLT-01, is a cutting-edge testing instrument developed by Cell Instruments, a leader in packaging testing solutions. Specially designed for detecting minute leaks in rigid and flexible nonporous packaging, the ASTM F2338 Micro Leak Tester utilizes the Vacuum Decay Method – a reliable, nondestructive technique that ensures the integrity of packaging.

Ideal for industries such as medical packaging, food packaging, pharmaceuticals, plastics, textiles, and adhesives, the ASTM F2338 Micro Leak Tester stands out for its ability to detect leaks as small as 1-3μm, making it an essential tool for quality assurance in manufacturing and research.

Key Features of the ASTM F2338 Micro Leak Tester (MLT-01)

The ASTM F2338 Micro Leak Tester is equipped with advanced technical features that set it apart from other leak detection solutions in the market. The following features ensure high sensitivity, versatility, and reliability for leak testing across a wide variety of materials and packaging types:

- Vacuum Decay Method: Uses a nondestructive testing approach to detect leaks in both rigid and flexible nonporous packages.

- High Sensitivity: Capable of detecting micro leaks as small as 1-3μm, ensuring even the smallest breaches are identified.

- Customizable Chamber Sizes: The MLT-01 offers flexible chamber sizes, tailored to accommodate various packaging materials.

- Straightforward Operation: Operated via a PLC system with an intuitive human-machine interface (HMI), making it easy for operators to perform leak testing.

- Comprehensive Testing Phases: The instrument follows a structured testing process, including FILL, SETTLE, TEST, and VENT, ensuring thorough assessment of package integrity.

- Effective Leak Rate Calculation: Accurate leak rate calculation ensures precise measurements for quality control and decision-making.

- Compliance with Industry Standards: Fully adheres to ASTM F2338, a widely recognized standard for micro leak testing, ensuring that results meet established benchmarks for packaging integrity.

Why You Need the ASTM F2338 Micro Leak Tester

In today’s competitive market, ensuring the integrity of packaging is crucial for preventing product contamination, spoilage, or compromised safety. The ASTM F2338 Micro Leak Tester provides an efficient, reliable, and nondestructive method for detecting leaks in packaging materials. By using the MLT-01 Micro Leak Tester, businesses can:

- Improve Product Safety: By detecting leaks, this tester ensures that products are sealed properly, reducing the risk of contamination.

- Enhance Packaging Reliability: Whether you deal with medical packaging, food packaging, or pharmaceutical packaging, the ASTM F2338 Micro Leak Tester guarantees that your packaging maintains its integrity throughout its lifecycle.

- Reduce Waste: Accurate leak detection prevents the need for costly product recalls due to packaging failures.

- Save Time and Resources: With its automated features and high sensitivity, the ASTM F2338 Micro Leak Tester helps streamline the quality control process, ensuring your packaging meets high standards without wasting valuable resources.

Application Areas of the ASTM F2338 Micro Leak Tester

The ASTM F2338 Micro Leak Tester is widely used across multiple industries due to its versatility in testing different types of packaging materials. Here are some key applications of the MLT-01 Micro Leak Tester:

- Medical Packaging: Ensuring the integrity of sterile medical packaging to maintain product safety and efficacy.

- Food Packaging: Detecting leaks in food packaging to prevent spoilage, contamination, and reduce waste.

- Pharmaceutical Packaging: Vital for testing pharmaceutical packaging to ensure it meets regulatory standards and maintains the efficacy of its contents.

- Plastics and Paper: Testing plastic and paper packaging materials for leaks to ensure product quality and safety.

- Textile Packaging: Verifying packaging for textile products to prevent damage and ensure secure transportation.

- Toiletry and Personal Care Packaging: Essential for ensuring leak-free packaging in personal care products.

- Adhesive and Printing Packaging: Important for packaging materials used in the adhesive and printing industries.

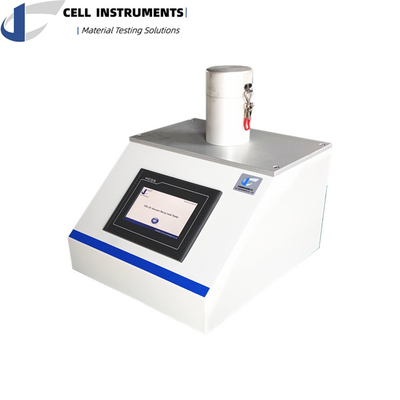

Technical Specifications of the ASTM F2338 Micro Leak Tester

| Test Range | 1Pa |

| Sensitivity | 1~3μm |

| Chamber size | Made-On-Demand |

| Vacuum pump | to be prepared by user |

| Power Supply | AC 110~220V 50Hz |

Compliance with Industry Standards

The MLT-01 Micro Leak Tester complies with the ASTM F2338 standard, making it an ideal choice for companies and laboratories seeking reliable, standardized testing for micro leaks in packaging. Meeting this critical industry standard ensures that the tester delivers consistent, repeatable results across various testing scenarios.

Why Choose the ASTM F2338 Micro Leak Tester by Cell Instruments?

Cell Instruments has long been a trusted name in the field of packaging testing, and the ASTM F2338 Micro Leak Tester exemplifies the company’s commitment to providing high-quality, innovative testing solutions. Our team of experts ensures that each unit is thoroughly tested for accuracy and reliability, giving you peace of mind knowing that your testing equipment meets the highest standards.![]()