ASTM F2338 Vacuum Decay Leak Tester Non-Destructive Leak Detection Equipment Pharmaceutical Packaging Precise Leak Test

| Test Range | 1Pa | Sensitivity | 1~3μm |

|---|---|---|---|

| Chamber Size | Made-On-Demand | Vacuum Pump | To Be Prepared By User |

| Power Supply | AC 110~220V 50Hz |

ASTM F2338 Vacuum Decay Leak Tester Non-Destructive Leak Detection Equipment Pharmaceutical Packaging Precise Leak Test

![]()

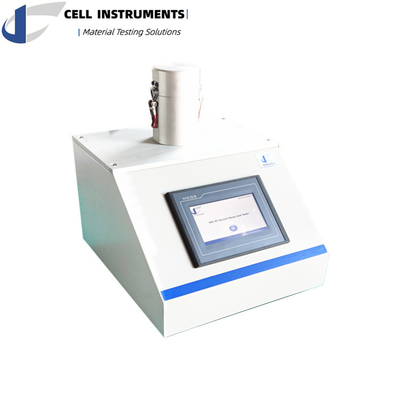

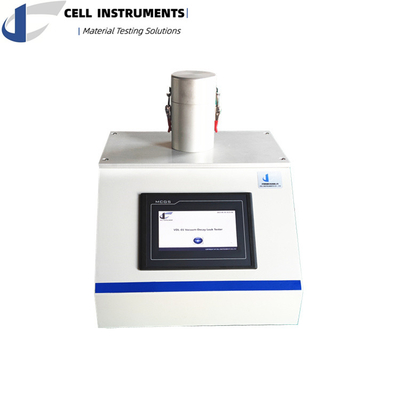

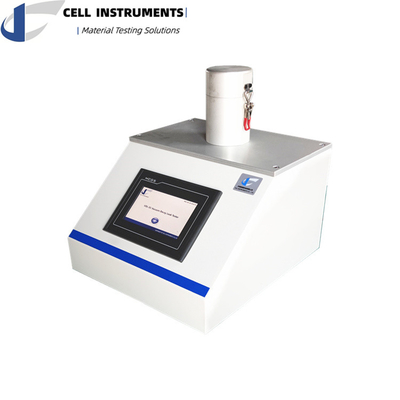

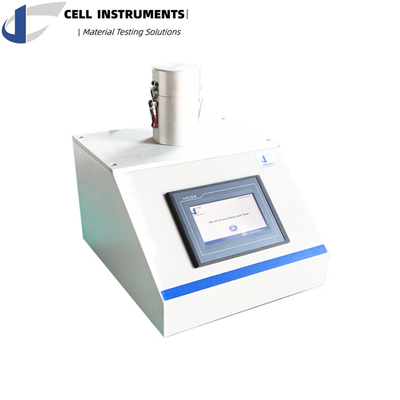

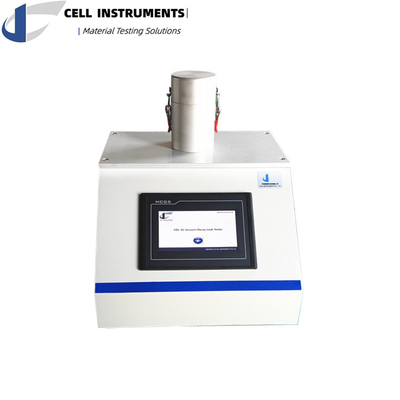

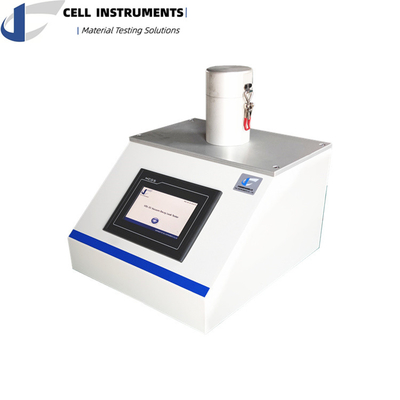

The ASTM F2338 Vacuum Decay Leak Tester (Model MLT-01 Micro Leak Tester) from Cell Instruments is an industry-leading, non-destructive leak testing instrument designed to deliver high-precision leak detection for a broad spectrum of packaging applications. Leveraging the vacuum decay method, the MLT-01 performs sensitive and quantitative leakage testing on both rigid and flexible nonporous packaging, meeting the demands of industries where safety, quality, and reliability are paramount. Key sectors include pharmaceuticals, food, packaging materials, cosmetics, and electronic components, each requiring exacting standards of packaging integrity.

Engineered for ease of use with sophisticated performance, the ASTM F2338 Vacuum Decay Leak Tester offers high sensitivity, advanced data recording, and compliance with the ASTM F2338 standard, making it an essential tool for quality control in both research and production environments.

| Test Range | 1Pa |

| Sensitivity | 1~3μm |

| Chamber size | Made-On-Demand |

| Vacuum pump | to be prepared by user |

| Power Supply | AC 110~220V 50Hz |

Key Features of the ASTM F2338 Vacuum Decay Leak Tester

-

Customizable Test Chambers: Designed to accommodate a variety of packaging sizes and types, the test chamber on the ASTM F2338 Vacuum Decay Leak Tester can be tailored to meet diverse testing requirements, ensuring precise results for different packaging profiles.

-

High Sensitivity Detection: With an ability to detect microscopic leaks down to 1-3 microns, the ASTM F2338 Vacuum Decay Leak Tester delivers results with outstanding sensitivity. This high accuracy is critical for industries where even minor packaging defects can lead to product contamination or spoilage.

-

Vacuum Decay Method for Accurate Leak Rate Calculation: The vacuum decay technology employed by the tester quantifies leak rates with extreme precision, providing reliable and reproducible data vital to stringent quality assurance protocols.

-

User-Friendly Operation with Intuitive HMI: The MLT-01 features an intuitive human-machine interface (HMI) that simplifies the operation process, reducing training time and enhancing usability. Its PLC system ensures consistent performance and ease of navigation across testing phases.

-

ASTM F2338 Compliance: Compliance with ASTM F2338 ensures that the MLT-01 Micro Leak Tester aligns with internationally recognized standards for leak testing in packaging. This guarantees it meets regulatory requirements across pharmaceutical, food, and other sensitive applications.

-

Versatile Application Across Industries: From pharmaceutical packaging to food containers and beyond, the MLT-01 is adaptable to a broad range of materials and packaging formats. Its versatility extends its utility across diverse sectors including plastics, paper, and adhesives.

How the ASTM F2338 Vacuum Decay Leak Tester Works

The ASTM F2338 Vacuum Decay Leak Tester operates through a series of precisely controlled testing phases: FILL, SETTLE, TEST, and VENT. During the process, a package is placed in the custom test chamber, where a vacuum is applied. Any potential leaks are detected based on changes in vacuum levels, with the instrument calculating the leak rate accurately. This approach offers a non-destructive, quick, and repeatable method for assessing package integrity without risking damage to the packaging or its contents.

Why the ASTM F2338 Vacuum Decay Leak Tester is Essential for Quality Control

The ASTM F2338 Vacuum Decay Leak Tester provides a critical quality control function by ensuring that packages remain airtight and secure, preserving product integrity and consumer safety. Especially in the pharmaceutical industry, where leakage can lead to contamination or reduced efficacy of the product, a reliable leak tester like the MLT-01 is essential. By identifying potential defects before products reach the market, the MLT-01 helps companies reduce waste, minimize recalls, and safeguard their brand reputation.

Applications of the ASTM F2338 Vacuum Decay Leak Tester

The ASTM F2338 Vacuum Decay Leak Tester is highly applicable across numerous industries:

- Pharmaceutical: Provides essential testing to confirm airtight packaging for medications, ensuring they remain sterile and effective.

- Food and Beverage: Detects leaks in food and beverage packaging to prevent contamination, spoilage, and extend shelf life.

- Cosmetic and Toiletry: Ensures personal care products are sealed to prevent leakage and maintain their effectiveness.

- Electronics: Prevents moisture ingress in sensitive electronic components, preserving performance and longevity.

- Medical Device Packaging: Confirms the integrity of medical packaging, essential for regulatory compliance and patient safety.

- General Packaging and Materials: Ideal for testing plastics, textiles, paper, and adhesive-based packaging to ensure consistent quality and protection.

Technical Specifications of the ASTM F2338 Vacuum Decay Leak Tester

- Detection Range: Capable of detecting leaks as small as 1-3 microns, providing sensitive and reliable results.

- Operating Phases: FILL, SETTLE, TEST, VENT—structured to assess leak points and calculate leak rate efficiently.

- Control System: Operated via an advanced PLC system paired with a user-friendly HMI, making setup and data collection straightforward.

- Chamber Design: Customizable chambers ensure compatibility with various package sizes and formats, providing versatile usage.

- Compliance: Conforms to ASTM F2338 requirements, ensuring adherence to industry standards.

Benefits of Using the ASTM F2338 Vacuum Decay Leak Tester

- Non-Destructive Testing: Allows manufacturers to test samples without damaging them, conserving resources and minimizing waste.

- High-Precision Leak Detection: Offers unmatched sensitivity that ensures even the smallest leaks are identified, safeguarding product quality.

- Versatile for Diverse Packaging Needs: Adaptable to both rigid and flexible nonporous packages, making it ideal for a wide range of applications.

- Regulatory Compliance: Meets ASTM F2338 standards, ensuring alignment with global quality assurance protocols.

![]()