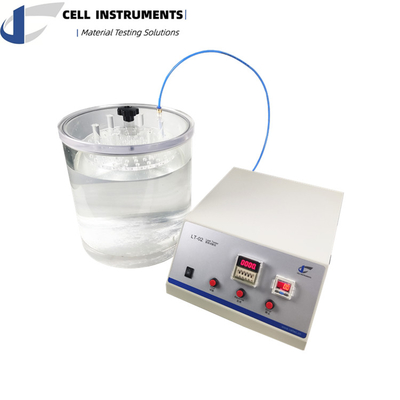

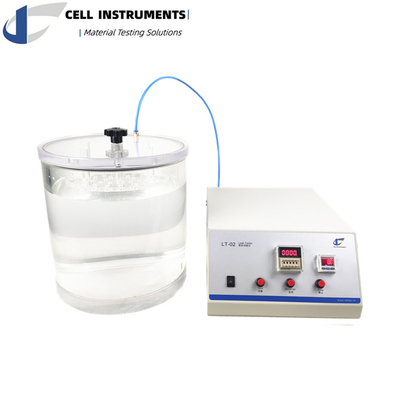

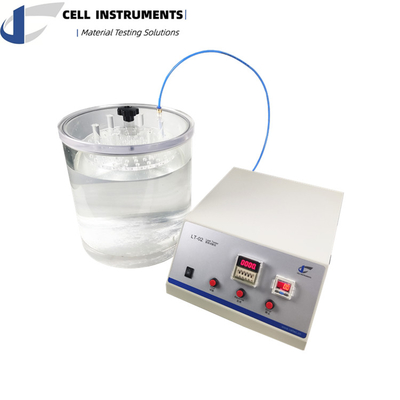

Vacuum Tightness Tester Vacuum ASTM D3078 Leakage Detector Chemical Packaging Packaging Integrity Testing Machine

| Test Range | 0~-90 KPa | Chamber | Acrylic Cylinder Shape |

|---|---|---|---|

| Test Space | Φ270*H210mm (Inside Usable) | Compressed Air | 0.7MPa (Prepared By User) |

| Power | 110V, Or 220V 50/60Hz |

Vacuum Tightness Tester Vacuum ASTM D3078 Leakage Detector Chemical Packaging Packaging Integrity Testing Machine

![]()

![]()

ASTM D3078 Leakage Detector: Ensuring Packaging Integrity

Introduction to the ASTM D3078 Leakage Detector

Cell Instruments proudly introduces the ASTM D3078 Leakage Detector, also known as the LT-02 Leak Tester, a pioneering automatic vacuum tester engineered to assess the integrity of package seals. This advanced instrument epitomizes our commitment to delivering state-of-the-art testing solutions tailored for a wide array of industries, including plastics, paper, textiles, food, pharmaceuticals, toiletries, printing, adhesives, and more. By utilizing the ASTM D3078 Leakage Detector, businesses can uphold product quality and compliance with industry standards, ensuring that their packaging meets rigorous safety and reliability requirements.

Technical Features of the ASTM D3078 Leakage Detector

The ASTM D3078 Leakage Detector is designed in accordance with the ASTM D3078 standard, which outlines the methods for detecting gross leaks in flexible packaging that contains headspace gas through bubble emission. Key technical features include:

-

Stable Vacuum Generation: The LT-02 employs a Venturi tube mechanism to achieve a stable vacuum. This innovative design considers the availability of compressed air at user facilities, achieving high vacuum levels of up to -90 kPa for reliable testing.

-

Adjustable Test Time: Our ASTM D3078 Leakage Detector features precise and adjustable test time settings, allowing users to customize testing parameters according to specific needs and product types.

-

SMC Branded Vacuum Pressure Switch: For enhanced accuracy and consistency, the tester incorporates a reliable SMC-branded vacuum pressure switch, ensuring trustworthy results every time.

-

Transparent Chamber: The LT-02 includes a robust, transparent chamber that can be customized for different sizes and shapes, providing visibility during testing.

-

Compatibility with Vacuum Pumps: The instrument can be adapted for use with a vacuum pump, enabling higher vacuum levels and compliance with ASTM D4991 standards, further enhancing its testing capabilities.

Why Choose the ASTM D3078 Leakage Detector?

The ASTM D3078 Leakage Detector is an essential tool for quality control and assurance in the packaging industry. Its advanced features and reliable testing mechanisms make it indispensable for companies seeking to ensure the integrity of their package seals. By integrating the ASTM D3078 Leakage Detector into your quality assurance processes, businesses across plastics, paper, textile, food, pharmaceutical, toiletry, printing, and adhesive sectors can confidently maintain the quality and safety of their products.

Purpose of the ASTM D3078 Leakage Detector

The primary purpose of the ASTM D3078 Leakage Detector is to evaluate the integrity of package seals. It plays a crucial role in verifying that packaging adequately protects products from external factors. By performing seal integrity tests, businesses can scrutinize sustainable packaging options, explore cost-effective solutions, and optimize production line sealing parameters. The ASTM D3078 Leakage Detector is dedicated to maintaining product quality and safety by ensuring the reliability of package seals.

Applications of the ASTM D3078 Leakage Detector

The ASTM D3078 Leakage Detector is applicable in a variety of industries and research facilities, including enterprises, colleges, universities, and official laboratories. Its applications include:

- Scrutinizing Sustainable Packaging Alternatives: Assessing new materials and designs for environmental impact.

- Evaluating Cost-Effective Packaging Solutions: Identifying economically viable options without compromising quality.

- Adjusting Production Line Sealing Parameters: Fine-tuning processes to enhance efficiency and reduce waste.

- Upholding Product Quality and Safety: Conducting reliable seal integrity tests to protect consumer interests.

Main Parameters of the ASTM D3078 Leakage Detector

| Specification | LT-02 |

|---|---|

| Test Range | 0~-90 kPa |

| Chamber | Acrylic cylinder shape |

| Test Space | Φ270*H210mm (Usable Interior) |

| Compressed Air | 0.7MPa (Provided by the user) |

| Power Supply | 110V or 220V 50/60Hz |

Available Chambers

The ASTM D3078 Leakage Detector comes with a variety of chamber options to meet diverse testing needs:

- Cylindrical Shapes: Available in various heights and diameters, such as φ270mm, φ364mm, φ464mm, etc.

- Cuboid Shapes: Customizable lengths (L), widths (W), and heights (H) to suit specific product requirements.

Compliance and Standards

The ASTM D3078 Leakage Detector adheres to the ASTM D3078 standard, ensuring that it meets industry benchmarks for leak detection in packaging. This compliance guarantees that users can trust the results provided by this innovative testing instrument, contributing to enhanced quality assurance practices.

![]()