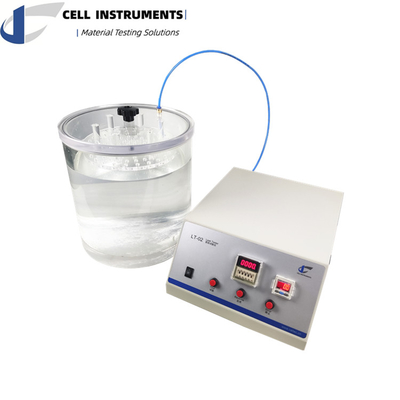

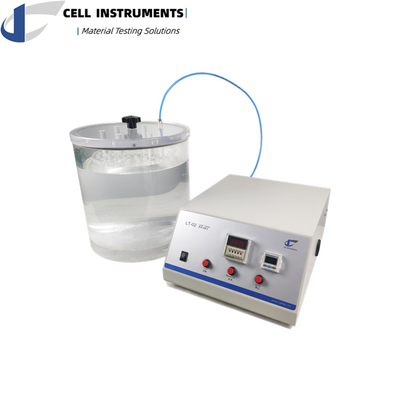

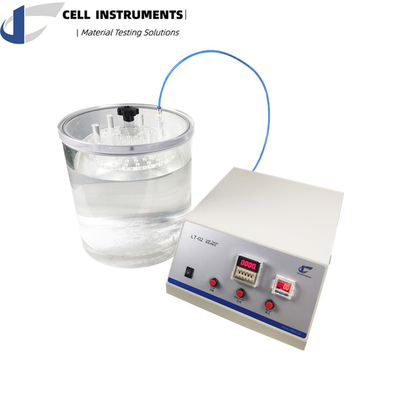

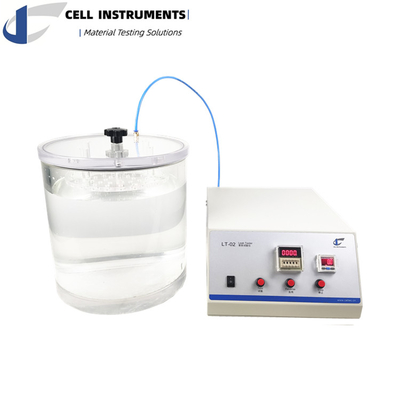

Vacuum Leakage Tester Package Seal Tester Packaging Air Tightness Test Instrument Packaging Laboratory Testing Equipment

| Test Range | 0~-90 KPa | Chamber | Acrylic Cylinder Shape |

|---|---|---|---|

| Test Space | Φ270*H210mm (Inside Usable) | Compressed Air | 0.7MPa (Prepared By User) |

| Power | 110V, Or 220V 50/60Hz |

Vacuum Leakage Tester Package Seal Tester Packaging Air Tightness Test Instrument Packaging Laboratory Testing Equipment

![]()

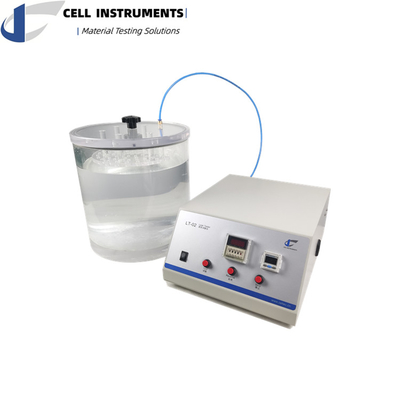

Product Overview: Vacuum Leakage Tester for Packaging Quality Control

The Vacuum Leakage Tester LT-02 from Cell Instruments is a high-precision testing instrument meticulously designed to assess the integrity and air-tightness of sealed packages. Meeting the rigorous standards of ASTM D3078 and compatible with ASTM D4991, this Vacuum Leakage Tester is essential for industries that prioritize packaging quality, such as pharmaceuticals, food and beverage, textiles, adhesives, and more. By utilizing controlled vacuum settings, the LT-02 performs a reliable bubble emission test to detect leaks in flexible packaging, thereby ensuring product safety, freshness, and extended shelf life.

| Test Range | 0~-90 KPa |

| Chamber | Acrylic cylinder shape |

| Test Space | Φ270*H210mm (Inside Usable) |

| Compressed Air | 0.7MPa (Prepared by user) |

| Power | 110V, or 220V 50/60Hz |

Why Choose the LT-02 Vacuum Leakage Tester?

- Advanced Seal Integrity Analysis: The Vacuum Leakage Tester performs precise seal tests to detect any packaging breaches, providing reliable data on seal strength, durability, and air-tightness.

- Wide Range of Applications: Suitable for diverse industries, including food, pharmaceuticals, packaging, and more, the LT-02 is a versatile tool used in both industrial settings and research facilities for accurate vacuum leakage testing.

- User-Friendly Operation: With adjustable testing parameters and a clear display, the LT-02 Vacuum Leakage Tester ensures efficient workflows and optimized testing accuracy.

Core Features of the LT-02 Vacuum Leakage Tester

The LT-02 boasts cutting-edge features that make it an indispensable vacuum leak tester for package integrity. Here’s an overview:

- High Vacuum Stability: Equipped with a Venturi tube design, the LT-02 reaches vacuum levels up to -90 KPa, allowing for robust testing conditions under controlled environments.

- Adjustable Testing Duration: Customizable test time settings provide flexibility, enabling operators to adapt the vacuum leakage testing process to suit various product needs.

- Transparent Testing Chamber: A clear acrylic chamber ensures easy observation, while customizable chamber sizes accommodate different product shapes and sizes, from cylindrical to cuboid.

- High Compatibility: For more rigorous testing, the LT-02 Vacuum Leakage Tester can be paired with a vacuum pump, achieving higher vacuum levels in line with ASTM D4991 standards.

- SMC Branded Vacuum Pressure Switch: Integrated with a reliable vacuum pressure switch from SMC, the LT-02 ensures stable and consistent vacuum levels, enhancing test accuracy.

Applications of the Vacuum Leakage Tester in Packaging Quality Assurance

- Pharmaceuticals: Safeguard medical supplies by testing packaging for secure seals to prevent contamination.

- Food and Beverage: Maintain freshness by verifying air-tightness in packaged products.

- Textiles and Adhesives: Quality testing in textile and adhesive packaging to ensure product reliability.

- Research Facilities and Quality Labs: Extensively used in universities, research institutions, and industry labs to explore sustainable packaging and enhance packaging materials.

Benefits of Using the LT-02 Vacuum Leakage Tester

The LT-02 Vacuum Leakage Tester is a valuable tool for quality control teams aiming to uphold packaging standards across production lines. With its advanced seal-testing technology, this vacuum leak tester can:

- Identify Packaging Weaknesses: The vacuum test reveals any compromised areas in the seal.

- Reduce Product Returns and Waste: Early detection of defective seals leads to fewer product recalls.

- Optimize Seal Settings: Adjust parameters in production lines based on testing data for optimal packaging integrity.

- Support Sustainable Packaging: Provides reliable data for companies exploring eco-friendly materials to replace conventional packaging.

Technical Specifications

- Testing Range: 0 to -90 KPa

- Chamber: Clear acrylic cylinder with various dimensions (φ270*H210mm standard)

- Compressed Air Requirement: 0.7 MPa (supplied by user)

- Power Supply: 110V or 220V, 50/60Hz

Available Chamber Options for Versatile Testing Needs

- Cylindrical chambers with different diameters and heights, such as φ270mm, φ364mm, φ464mm.

- Cuboid chambers offering customizable lengths (L), widths (W), and heights (H) to accommodate various package dimensions.

Compliance and Standards

This Vacuum Leakage Tester aligns with the ASTM D3078 standard for bubble emission testing and ASTM D4991 for advanced testing requirements, making it suitable for applications demanding high levels of quality assurance.

Why the LT-02 Vacuum Leakage Tester is Essential for Packaging Integrity

The LT-02 plays a pivotal role in the following areas:

- Upholding Product Quality: Ensures that sealed packages maintain product integrity, extending shelf life.

- Improving Production Efficiency: Testing results guide production adjustments for consistent seal quality.

- Exploring Cost-Effective Solutions: Enables businesses to experiment with packaging alternatives without compromising quality.

- Mitigating Product Recalls: Early detection of leaks helps avoid costly product recalls and maintains customer trust.

FAQs

-

What type of packages can be tested with the Vacuum Leakage Tester?

The LT-02 is suitable for flexible packaging that contains headspace gas, commonly used in food, pharmaceuticals, and consumer goods. -

What is the benefit of having a transparent chamber?

The clear chamber allows operators to visually monitor the package during testing, making it easier to observe any bubble emissions or leaks. -

How does the LT-02 contribute to sustainable packaging?

By identifying weaknesses in seals, businesses can explore eco-friendly materials that maintain package integrity, contributing to sustainability goals. -

Can the Vacuum Leakage Tester handle high-volume testing?

Yes, the LT-02’s adjustable testing parameters make it ideal for high-throughput environments, improving efficiency on production lines. -

Is the LT-02 compatible with all vacuum pumps?

The LT-02 can be modified for compatibility with various vacuum pumps, especially when higher vacuum levels are required for specific testing needs.

![]()