Melt Flow Rate Tester Extrusion Plastometers For Thermoplastics Material

| Measuring Range(MFR) | 0.1-400.00g/10min | Temperature Range | Ambient~450°C |

|---|---|---|---|

| Cylinder Internal Diameter | 9.550mm ± 0.025mm | Cylinder Length | 160mm |

| Power Supply | AC220V, 50Hz | Dimensions | 400mm×500mm×600mm |

Melt Flow Rate Tester Extrusion Plastometers For Thermoplastics Material

![]()

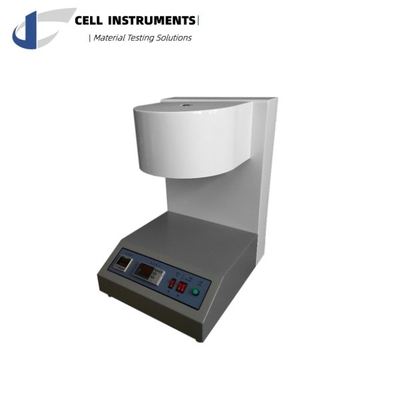

RZ-A Melt Flow Rate Tester: Advanced Extrusion Plastometers for Thermoplastics

The RZ-A Melt Flow Rate Tester is engineered for precise and reliable analysis of the melt flow rate (MFR) in thermoplastic materials. Essential for manufacturers, quality inspection agencies, and educational institutions, this Melt Flow Rate Tester delivers consistent and accurate data on polymer flow characteristics, supporting a wide range of industries including packaging, medical, food, and beverage production. With an intelligent temperature control system and dual-position time relay output, the RZ-A model achieves exceptional temperature accuracy and stability, ensuring repeatable results for high-quality testing outcomes.

Key Features of the RZ-A Melt Flow Rate Tester

-

Precision PID Temperature Control: The Melt Flow Rate Tester is equipped with a PID temperature controller and dibit time relay, achieving accurate temperature control within a range of ambient to 450°C. With a precision of ±0.2°C, this system minimizes overshoot, ensuring quick stability and effective thermal management for a broad spectrum of thermoplastic testing applications.

-

Dual Cutting Modes for Versatile Testing: This Melt Flow Rate Tester offers both timed and manual cutting methods, allowing operators to customize intervals and times for different testing needs. This flexibility is particularly valuable for labs and production facilities requiring tailored testing protocols.

-

High Efficiency and Stability: The RZ-A Melt Flow Rate Tester rapidly reaches the target temperature, helping labs save time and streamline testing workflows. The durable construction and high-quality materials provide stable performance even under continuous use, making this tester ideal for both research and industrial settings.

-

User-Friendly Operation: Designed with usability in mind, the Melt Flow Rate Tester incorporates an intuitive interface, ensuring easy setup and operation for users at any skill level. High accuracy in both temperature control and time measurements further enhances test reliability.

-

Broad Applicability Across Industries: From packaging and medical fields to educational research and quality control labs, the RZ-A Melt Flow Rate Tester supports testing on various thermoplastics, providing essential data for material properties, compliance checks, and product development.

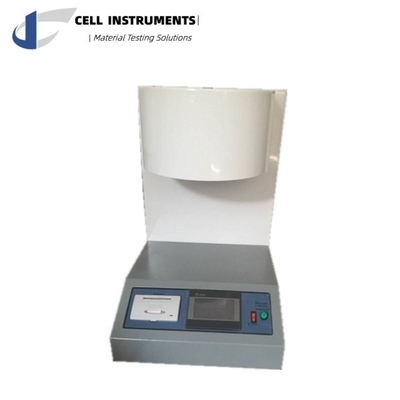

Technical Specifications of the RZ-A Melt Flow Rate Tester

| Items | Parameters | ||||

| Models | RZ-A | RZ-B | RZ-W | RZ-C | RZ-H |

| Method | MFR | MFR&MVR | |||

| Control/Display | LED | PLC, touch Screen | PC, Touch Screen, PLC | PLC, Touch Screen | |

| Software | N/A | Yes | N/A | ||

| Micro Printer | N/A | N/A | Yes | ||

| Measuring Range/10min | 0.1-400g | 0.1-800g(MFR) 0.1-800cm³(MVR) |

0.1-3000g(MFR) 0.1-3000cm³(MVR) |

(0.01~200)g(MFR) (0.1~2500)cm³(MVR) |

|

| Temperature Range | Ambient~450°C | ||||

| Temp. Precision | ±0.2°C | ±0.5°C | ±0.2°C | ||

| Time Accuracy | 1S or 0.01S | 0.1S | |||

| Disp. Precision | 0.01mm | ||||

| Load | Full Load 0.325~21.6kg | ||||

| Cutting Mode | Manual, Time | Time; Auto | Time; Auto | ||

| Cylinder Diameter | 9.550mm ± 0.025mm | ||||

| Cylinder Length | 160mm | ||||

| Die | Tungsten Carbide, L8.000mm ± 0.025mm, Internal Diameter 2.095mm ± 0.005mm | ||||

| Power | 0.45 KW | 0.5 KW | 0.45 KW | ||

| Power Supply | AC220V, 50Hz | ||||

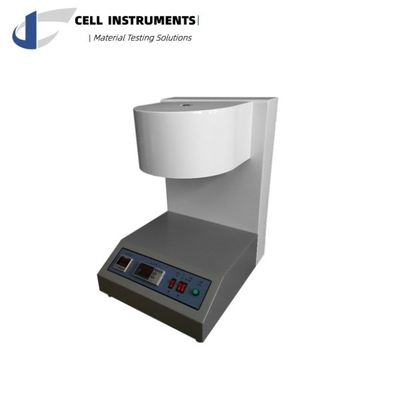

Advantages of the RZ-A Melt Flow Rate Tester

-

Enhanced Accuracy and Control: With its sophisticated PID controller and fine time relay, the RZ-A Melt Flow Rate Tester maintains exceptional control over temperature and cutting precision. This feature is crucial for producing reliable, reproducible results that are essential in research and production environments.

-

Customizable Testing Options: The dual cutting modes allow users to perform a range of melt flow tests, adapting to the needs of various plastic materials and production requirements. The flexibility supports customized research and development as well as routine quality checks in manufacturing.

-

High-Quality Construction and Durability: Built for long-lasting use, the RZ-A Melt Flow Rate Tester uses robust materials like tungsten carbide in critical components, ensuring sustained performance under high-temperature and high-load conditions.

-

User-Centric Design: The interface design prioritizes ease of use and provides consistent operational efficiency, making it suitable for training new lab technicians and handling large batches in industrial production.

-

Versatile Industry Applications: Whether for routine production control or in-depth material analysis, the Melt Flow Rate Tester meets the needs of diverse industries, including food and beverage packaging, pharmaceutical testing, and materials science research. The device provides critical insights into material properties, helping manufacturers ensure product quality and compliance.

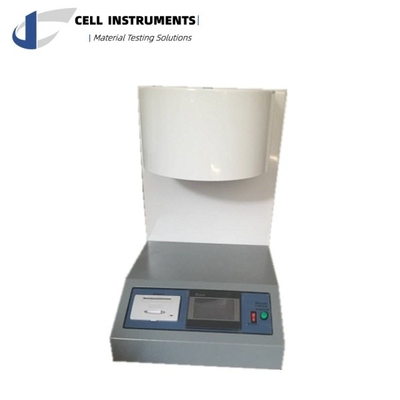

Applications of the RZ-A Melt Flow Rate Tester

The Melt Flow Rate Tester is instrumental in understanding the flow characteristics of thermoplastics, which is vital in determining material performance, processing suitability, and quality control across applications. It is widely used in:

- Packaging Testing: Evaluating polymers used in food and beverage containers, medical packaging, and other consumer goods.

- Automotive and Aerospace Components: Ensuring the integrity of thermoplastic materials in demanding applications.

- Educational and Research Institutions: Supporting teaching and research activities in materials science and engineering programs.

Why Choose the RZ-A Melt Flow Rate Tester?

The RZ-A Melt Flow Rate Tester delivers unmatched reliability and accuracy, offering industry-standard features that support comprehensive polymer testing. Whether in a lab or production line, it provides the consistency and control necessary for critical evaluations in material selection, product development, and regulatory compliance.

![]()

![]()