Gelbo Test Method Equipment For High Barrier Flexible Packaging Material By ASTM F392

| Flex Frequency | 45 /minute | Flex Angle | 440° (90 Mm) Or 400° (80 Mm) |

|---|---|---|---|

| Capacity | 3.5 N.m | Horizontal Stroke | 155 Mm Or 80 Mm |

| Stations | 3 | Sample Size | 280 Mm X 200 Mm |

| Power | 110~220V |

Gelbo Test Method Equipment For High Barrier Flexible Packaging Material By ASTM F392

![]()

Background

Gelbo Test Method Equipment plays a crucial role in evaluating the flex durability of flexible barrier materials. Flex durability, or Gelboflex resistance, refers to a material's ability to endure repetitive strain without failure. For industries utilizing flexible packaging, strong flex crack resistance is essential to minimize the risk of package perforation during shipping and handling. Maintaining package integrity ensures the contents remain protected and uncontaminated throughout the distribution process.

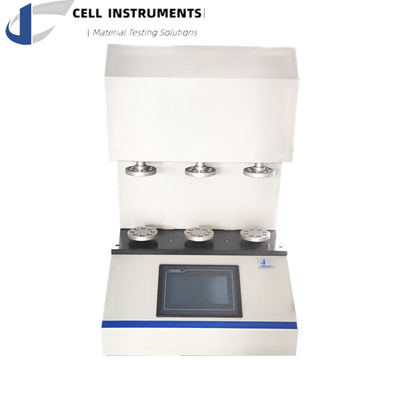

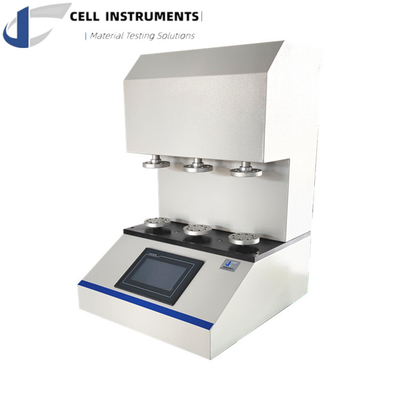

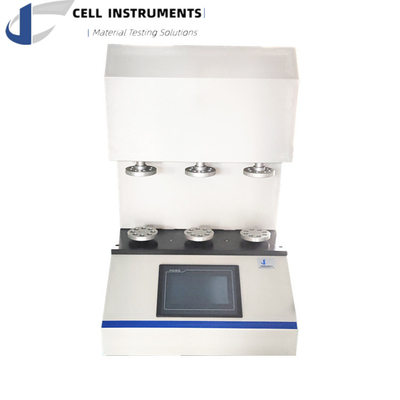

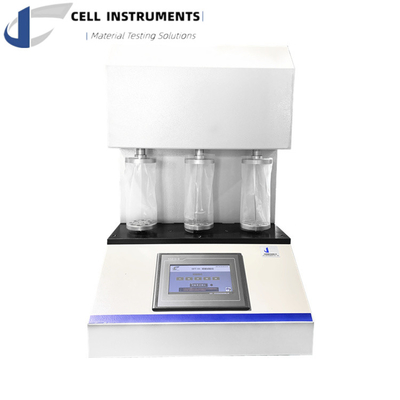

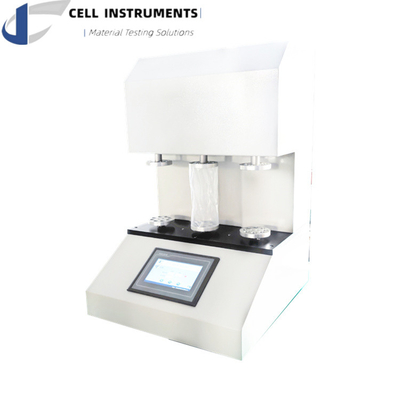

The GFT-02 Flex Durability Tester, commonly referred to as Gelbo Test Method Equipment, is specifically designed to assess how materials such as films, laminates, and coated films withstand repeated bending and twisting. By simulating real-world strain conditions, this equipment identifies potential weak points in packaging materials, helping manufacturers enhance their product durability standards.

Application

The Gelbo Test Method Equipment is widely used to test the flex durability of materials like plastic films, composites, laminates, and other flexible barrier materials. The equipment measures flex crack resistance by detecting pinholes or failures that may develop in the sample material after undergoing repetitive flexing. This ensures the packaging remains robust and intact, reducing the likelihood of leaks or contamination during transportation and storage.

Industries such as food, pharmaceuticals, textiles, adhesives, and packaging rely on flexible barrier materials to maintain product safety and quality. The GFT-02 Flex Durability Tester ensures these industries can confidently use materials that meet stringent quality standards.

Conformance to ASTM Standards

The Gelbo Test Method Equipment conforms to ASTM F392, which specifies the standard test method for determining the flex durability of flexible barrier materials. Compliance with ASTM F392 provides users with assurance that the testing procedures and outcomes meet globally recognized standards, offering a reliable measure of a material's durability.

Sampling and Motion Mechanics

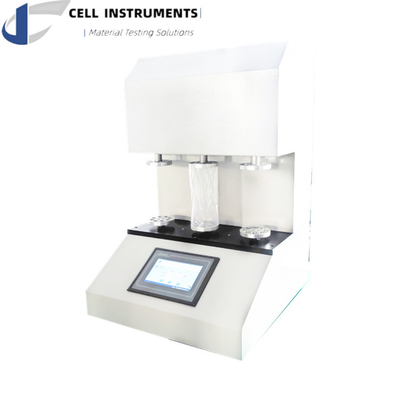

The Gelbo Test Method Equipment operates by securing a sample measuring 200 by 280 mm onto the mandrels of the tester. The test subject is then exposed to a series of twisting and horizontal compressions, effectively mimicking the mechanical stresses a material may encounter during real-life handling and distribution. The equipment initiates a twisting motion of 440 degrees within the first 90 mm of the stroke, combined with a linear horizontal movement of 65 mm. The testing occurs at a rate of 45 cycles per minute, allowing for comprehensive stress evaluation.

The GFT-02 provides five preset test modes:

- Mode A: Full flex for 1 hour (2,700 cycles)

- Mode B: Full flex for 20 minutes (900 cycles)

- Mode C: Full flex for 6 minutes (270 cycles)

- Mode D: Full flex for 20 cycles

- Mode E: Partial flex for 20 cycles

These different modes accommodate a wide range of testing scenarios, enabling users to assess materials under various simulated conditions.

Key Technical Features

The GFT-02 Gelbo Test Method Equipment boasts several advanced features designed for user convenience and enhanced testing accuracy:

- PLC Control System: The equipment is equipped with a PLC (Programmable Logic Controller) system, ensuring precise control and operation.

- Intuitive HMI Touch Screen Interface: The Human-Machine Interface (HMI) allows for easy navigation and setting adjustments, enhancing the user experience.

- Five Standard Test Modes: Users can select from five test conditions that replicate different levels of flexing stress.

- Three Test Stations: The GFT-02 has three test stations, facilitating simultaneous testing of multiple samples for increased efficiency.

- Long and Short Stroke Options: Easily switch between long and short strokes to match specific testing requirements.

Main Parameters

| Parameter | Specification |

|---|---|

| Model | GFT-02 |

| Flex Frequency | 45 cycles per minute |

| Flex Angle | 440° (90 mm) or 400° (80 mm) |

| Capacity | 3.5 N.m |

| Horizontal Stroke | 155 mm or 80 mm |

| Stations | 3/4 |

| Sample Size | 280 mm x 200 mm |

| Power | 110~220V |

These parameters ensure that the Gelbo Test Method Equipment meets a variety of testing needs across different materials and use cases.

Benefits of Using Gelbo Test Method Equipment

- Enhanced Material Quality Assurance: The GFT-02 helps identify materials with superior flex crack resistance, thereby improving the overall quality of flexible packaging.

- Reduced Risk of Product Contamination: By ensuring that materials can withstand repetitive flexing without developing pinholes, the equipment helps prevent leaks and maintain product safety.

- Compliance with Industry Standards: Testing in accordance with ASTM F392 ensures that the results are consistent with global standards, making it easier for companies to meet regulatory requirements.

- Versatile Testing Capabilities: The GFT-02’s multiple test modes and sample stations make it suitable for a range of industries and testing scenarios.

- User-Friendly Interface: The intuitive HMI touch screen interface simplifies operation, while the ability to switch between long and short strokes provides flexibility in testing setups.

Typical Industries Benefiting from Gelbo Test Method Equipment

The GFT-02 Flex Durability Tester serves various industries, including:

- Food and Beverage Packaging: Ensuring materials used for food and beverage containers remain intact during distribution.

- Pharmaceuticals: Testing barrier materials used in medical packaging to guarantee product safety.

- Textiles: Assessing the durability of coated fabrics or flexible textile laminates.

- Adhesives and Sealants: Evaluating the flex resistance of flexible sealant layers and coatings.

- Flexible Electronics Packaging: Ensuring protective layers on electronic devices remain free from damage under mechanical stress.

Why Choose Gelbo Test Method Equipment for Flex Durability Testing?

Choosing the GFT-02 means investing in a reliable and robust solution for flex durability testing:

- Accuracy and Repeatability: With precision control and standardized test conditions, the equipment provides consistent and reliable results.

- Multi-Station Testing: Simultaneously test up to three samples to boost efficiency.

- Compliance with ASTM Standards: The GFT-02 follows ASTM F392 for testing flexible barrier materials, ensuring adherence to industry standards.

- Customizable Testing: The ability to select different test modes allows users to tailor the equipment for specific material testing needs.

FAQ

Q1: What industries can benefit from the GFT-02 Flex Durability Tester?

A1: The GFT-02 Flex Durability Tester is applicable to a wide range of industries, including plastics, paper, textile, food, pharmaceuticals, toiletries, printing, adhesives, and more, where flexible barrier materials are crucial for packaging.

Q2: How does the GFT-02 Flex Durability Tester simulate repetitive strain?

A2: The tester employs a combination of twisting and horizontal compression motions, simulating the repetitive strain that flexible barrier materials may experience during distribution cycles.

Q3: Can users customize test conditions with the GFT-02 Flex Durability Tester?

A3: While the tester offers five pre-programmed test conditions (Mode A to Mode E), users have the flexibility to choose the most suitable condition for their specific testing requirements.

Q4: What is the significance of the ASTM F392 standard in the context of the GFT-02 Flex Durability Tester?

A4: The ASTM F392 standard ensures that the testing procedures and results adhere to industry-recognized standards, providing users with confidence in the accuracy and reliability of the GFT-02 Flex Durability Tester.

![]()