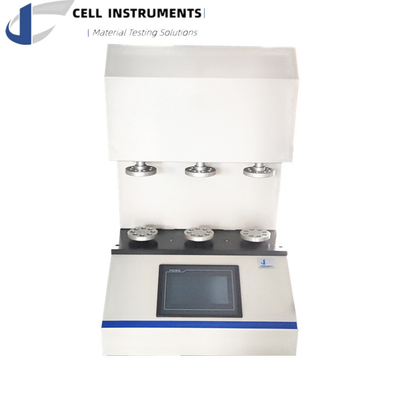

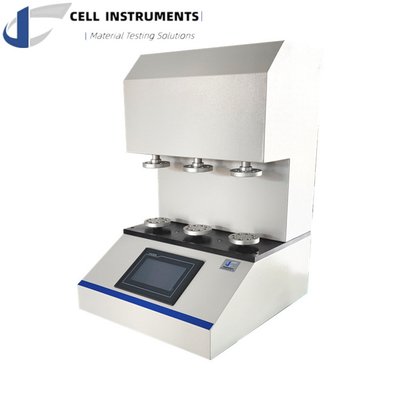

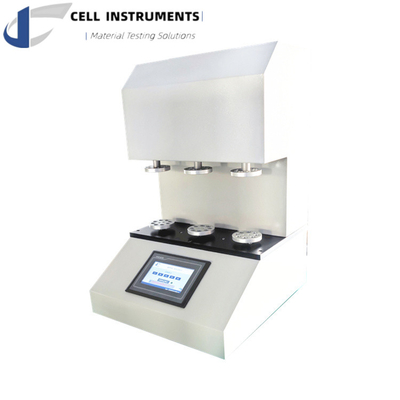

Coated Film Gelbo Flex Tester Quality Testing Equipment About ASTM F392 Gelbo Testing Method With Three Station

| Flex Frequency | 45 /minute | Flex Angle | 440° (90 Mm) Or 400° (80 Mm) |

|---|---|---|---|

| Capacity | 3.5 N.m | Horizontal Stroke | 155 Mm Or 80 Mm |

| Stations | 3 | Sample Size | 280 Mm X 200 Mm |

| Power | 110~220V |

Coated Film Gelbo Flex Tester Quality Testing Equipment About ASTM F392 Gelbo Testing Method With Three Station

![]()

Introduction

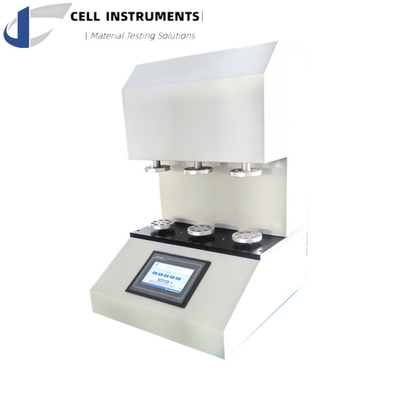

The Coated Film Gelbo Flex Tester is an essential instrument for assessing the flex durability of flexible barrier materials. Utilizing the ASTM F392 Gelbo testing method, this high-precision testing equipment evaluates the ability of films, composites, and coating films to endure repetitive strain, a critical characteristic known as Gelboflex resistance. By minimizing flex crack risks, the Coated Film Gelbo Flex Tester plays a pivotal role in safeguarding package integrity during distribution.

Background

Flex durability is crucial for flexible barrier materials, particularly in industries such as packaging, food, medicine, and beverages. The Coated Film Gelbo Flex Tester provides manufacturers with the ability to measure the flex resistance of materials, thereby ensuring that their products maintain integrity throughout their lifecycle. Strong flex crack resistance is vital as it directly impacts the likelihood of package perforation, which can lead to compromised contents and customer dissatisfaction.

Applications

The Coated Film Gelbo Flex Tester is designed to quantify flex failure by identifying pinholes that may form within the sample structure. This testing equipment is widely applicable across various sectors, including:

- Packaging: Ensures that films used in packaging maintain their integrity under stress.

- Food Industry: Tests food packaging films for durability, ensuring product safety and quality.

- Pharmaceuticals: Verifies that packaging materials for medications withstand distribution challenges.

- Beverages: Confirms that beverage containers retain their functionality and safety during transportation.

Testing Standards

The Coated Film Gelbo Flex Tester adheres to the ASTM F392 standard, ensuring that all testing procedures meet recognized industry benchmarks. This compliance enhances confidence in the accuracy and reliability of test results.

Testing Methodology

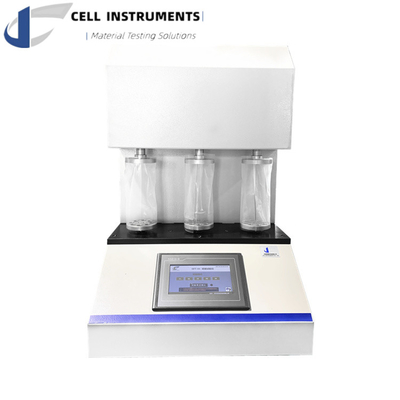

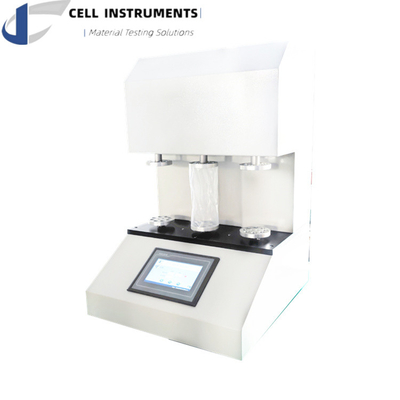

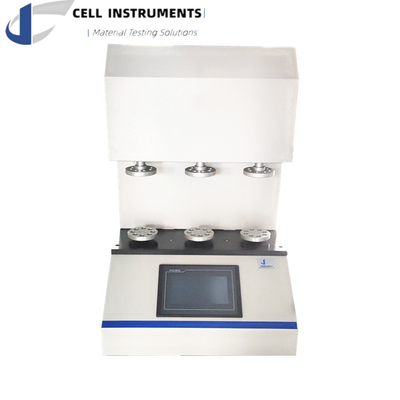

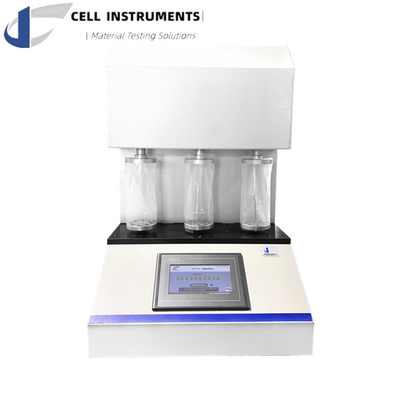

The Coated Film Gelbo Flex Tester employs a systematic approach to assess flex durability:

- Sample Preparation: A sample measuring 200 by 280 mm is secured onto mandrels.

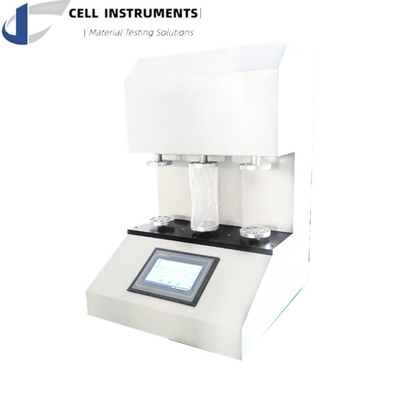

- Motion Simulation: The tester replicates repetitive strain through a combination of twisting (440 degrees) and horizontal compression (65 mm) movements at a speed of 45 cycles per minute.

- Test Modes: Users can select from five pre-programmed testing modes to suit their requirements:

- Mode A: Full flex for 1 hour (2,700 cycles)

- Mode B: Full flex for 20 minutes (900 cycles)

- Mode C: Full flex for 6 minutes (270 cycles)

- Mode D: Full flex for 20 cycles

- Mode E: Partial flex for 20 cycles

Technical Features

The Coated Film Gelbo Flex Tester incorporates state-of-the-art technology, including:

- PLC Control: Features an intuitive HMI touch screen interface for ease of operation.

- Flexible Testing Conditions: Quickly switch between long and short stroke modes to accommodate various testing needs.

- Three Test Stations: Allows for simultaneous testing, increasing efficiency.

Main Parameters

| Flex Frequency | 45 /minute |

| Flex Angle | 440° (90 mm) or 400° (80 mm) |

| Capacity | 3.5 N.m |

| Horizontal Stroke | 155 mm or 80 mm |

| Stations | 3/4 |

| Sample Size | 280 mm x 200 mm |

| Power | 110~220V |

Frequently Asked Questions (FAQ)

-

What industries can benefit from the Coated Film Gelbo Flex Tester?

- The Coated Film Gelbo Flex Tester is applicable in various industries, including plastics, paper, textiles, food, pharmaceuticals, toiletries, printing, and adhesives.

-

How does the Coated Film Gelbo Flex Tester simulate repetitive strain?

- The tester employs a combination of twisting and horizontal compression, effectively mimicking the repetitive strain that flexible barrier materials may encounter during distribution.

-

Can users customize test conditions with the Coated Film Gelbo Flex Tester?

- Yes, while the tester comes with five pre-programmed test modes (Mode A to Mode E), users can select the most suitable condition for their specific testing requirements.

-

What is the significance of the ASTM F392 standard in relation to the Coated Film Gelbo Flex Tester?

- The ASTM F392 standard ensures that the testing procedures and results adhere to industry-recognized standards, providing users with confidence in the accuracy and reliability of the Coated Film Gelbo Flex Tester.

![]()