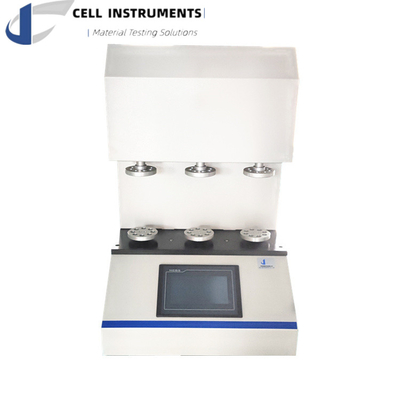

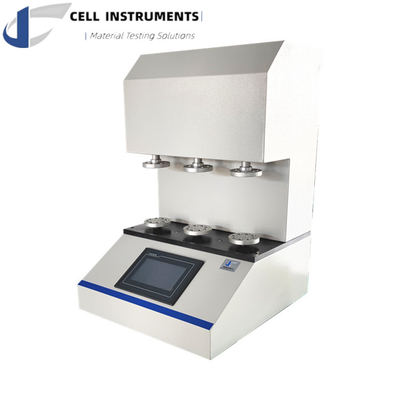

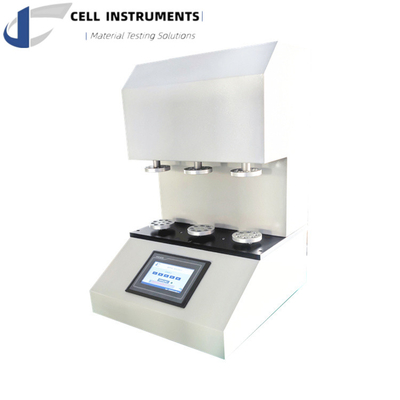

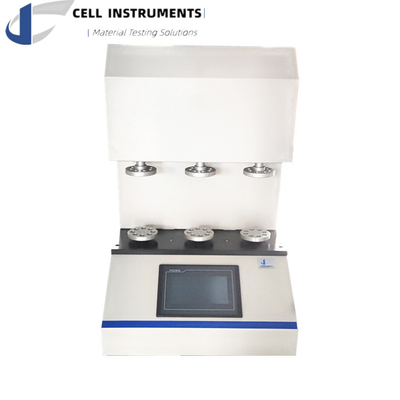

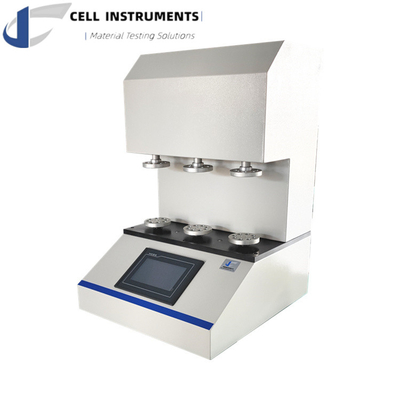

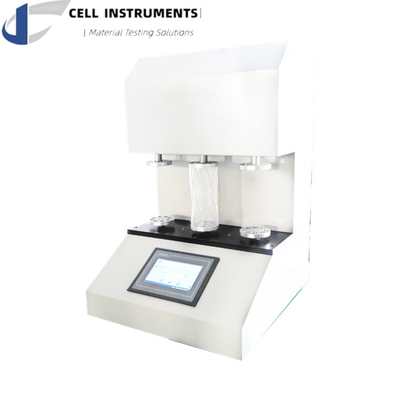

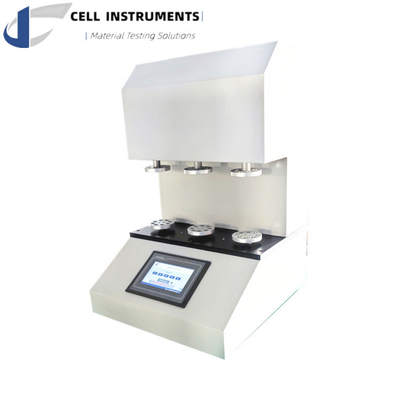

Gelbo Flex Tester For Laminated Film To Test Flex Durability Performance ASTM F392 Flexible Barrier Materials Tester

| Flex Frequency | 45 /minute | Flex Angle | 440° (90 Mm) Or 400° (80 Mm) |

|---|---|---|---|

| Capacity | 3.5 N.m | Horizontal Stroke | 155 Mm Or 80 Mm |

| Stations | 3 | Sample Size | 280 Mm X 200 Mm |

| Power | 110~220V |

Gelbo Flex Tester For Laminated Film To Test Flex Durability Performance ASTM F392 Flexible Barrier Materials Tester

![]()

Gelbo Flex Tester For Laminated Film – GFT-02 Flex Durability Tester for Evaluating Flex Durability Performance in Laminated Films, Composites, and Coated Materials. Compliant with ASTM F392 Standard for Flex Durability of Flexible Barrier Materials.

Background

The Gelbo Flex Tester For Laminated Film plays a vital role in assessing the durability of flexible barrier materials used in packaging. A key characteristic of flexible barrier materials is their ability to endure repetitive strain without compromising structural integrity. This ability, known as flex durability or Gelboflex resistance, is crucial for protecting contents from contamination, leakage, or damage. High flex crack resistance significantly reduces the risk of package perforation during distribution, ensuring that the packaging remains intact throughout its journey from manufacturing to end-user. For industries relying on flexible barrier packaging, such as food, pharmaceuticals, and consumer goods, maintaining package integrity is essential for product safety.

Application

The Gelbo Flex Tester For Laminated Film evaluates the resistance of materials to repeated flexing, simulating the strains encountered during handling, storage, and transport. The tester is suitable for a variety of materials, including laminated films, plastic films, paper, coated materials, and other composites. The testing process involves detecting pinholes and cracks that may develop in the film structure under flexing conditions, providing an accurate measure of the material's flex failure threshold. Maintaining excellent flex crack resistance helps prevent the development of holes during distribution, preserving the barrier properties of the packaging and protecting the contents inside.

Standards Compliance

The Gelbo Flex Tester For Laminated Film is designed to meet the specifications of ASTM F392, a globally recognized standard for evaluating the flex durability of flexible barrier materials. Compliance with ASTM F392 ensures that the testing procedures and results conform to industry standards, providing users with reliable and consistent data on material performance.

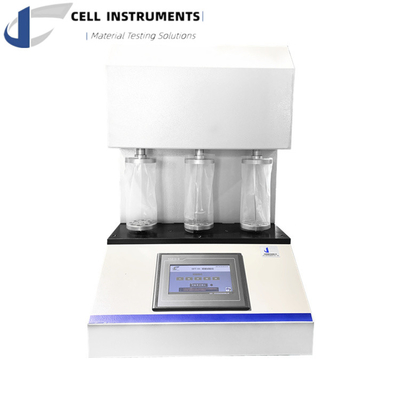

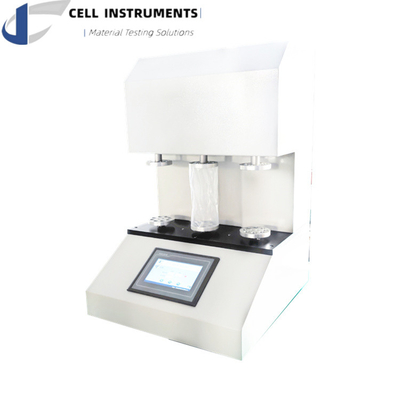

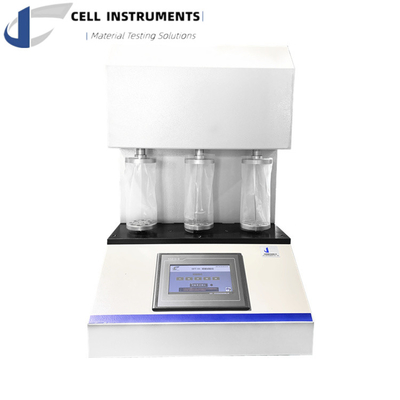

Sampling and Testing Procedure

The testing process in the Gelbo Flex Tester For Laminated Film involves securing a sample measuring 200 mm by 280 mm onto the mandrels. The sample undergoes a dual-action flexing motion consisting of twisting and linear compression, which mimics the real-world stresses that flexible barrier materials encounter. This testing approach allows for the detection of potential weaknesses that could affect packaging performance. The flexing mechanism includes:

- Twisting Motion: The twisting motion spans 440 degrees within the first 90 mm of the stroke.

- Linear Motion: A horizontal compression of 65 mm follows, completing the flexing action.

- Cycle Speed: The process occurs at a frequency of 45 cycles per minute.

The Gelbo Flex Tester For Laminated Film features five pre-programmed test conditions, offering users the flexibility to choose the most suitable testing protocol for their material:

- Mode A: Full flex for 1 hour (2,700 cycles)

- Mode B: Full flex for 20 minutes (900 cycles)

- Mode C: Full flex for 6 minutes (270 cycles)

- Mode D: Full flex for 20 cycles

- Mode E: Partial flex for 20 cycles

Technical Features

The Gelbo Flex Tester For Laminated Film is equipped with advanced technical capabilities, designed to facilitate accurate and user-friendly testing:

- PLC Control with HMI Touch Screen Interface: Provides intuitive navigation and control over test settings.

- Multiple Testing Modes: Offers five standard test modes to accommodate a range of testing requirements.

- Three Test Stations: Enables simultaneous testing of multiple samples for higher throughput.

- Adjustable Stroke Modes: Easily switch between long and short stroke modes depending on the specific testing needs.

- High Capacity and Flexibility: The system accommodates a wide range of materials, making it suitable for various industries.

Main Parameters

| Parameter | Specification |

|---|---|

| Model | GFT-02 |

| Flex Frequency | 45 cycles per minute |

| Flex Angle | 440° (90 mm) or 400° (80 mm) |

| Capacity | 3.5 N·m |

| Horizontal Stroke | 155 mm or 80 mm |

| Number of Test Stations | 3/4 |

| Sample Size | 280 mm x 200 mm |

| Power Supply | 110V-220V |

Applications Across Industries

The Gelbo Flex Tester For Laminated Film serves a wide range of industries where flexible barrier materials are vital for packaging and product protection:

- Food and Beverage Packaging: Ensures that laminated films used in food and beverage packaging can withstand distribution stresses without compromising the barrier properties.

- Pharmaceutical Packaging: Verifies the durability of materials used in pharmaceutical packaging, where maintaining sterility and integrity is essential.

- Consumer Goods Packaging: Tests the strength and durability of packaging materials used for toiletries, cosmetics, and household items.

- Industrial Packaging: Suitable for assessing the flex resistance of packaging materials used in heavy-duty industrial applications.

- Research and Development: Aids in material development by providing valuable data on the durability and performance of new materials.

Advantages of Using the Gelbo Flex Tester For Laminated Film

- Accurate Simulation: The Gelbo Flex Tester provides realistic simulation of the stresses that laminated films and barrier materials experience during handling and transportation, enabling reliable assessment of flex durability.

- Compliance with Industry Standards: Testing according to ASTM F392 ensures consistency and reliability in material performance data, which is critical for meeting regulatory requirements.

- Enhanced Packaging Integrity: By identifying materials with superior flex crack resistance, manufacturers can improve the durability of their packaging, reducing the risk of contamination, leakage, and product loss.

- Versatile Testing Capabilities: With multiple modes and adjustable settings, the tester can accommodate various materials and testing protocols, making it suitable for diverse applications.

FAQs

-

Q: What materials can be tested using the Gelbo Flex Tester For Laminated Film?

A: The Gelbo Flex Tester is suitable for testing a variety of materials, including laminated films, plastic films, paper, composites, and coated materials. -

Q: How does the Gelbo Flex Tester For Laminated Film assess flex durability?

A: The tester simulates repetitive strain by applying a combination of twisting and linear compression motions to the sample, mimicking real-world conditions that packaging materials may encounter. -

Q: What are the benefits of testing to ASTM F392 with the Gelbo Flex Tester For Laminated Film?

A: Testing in accordance with ASTM F392 ensures that the procedures and results adhere to recognized industry standards, providing confidence in the material's performance and quality. -

Q: Can the Gelbo Flex Tester accommodate custom testing requirements?

A: Yes, the Gelbo Flex Tester allows users to select from five pre-programmed test conditions, enabling customization to meet specific testing needs.

![]()