Heat Sealing Testing Machine By PID Control Heat Seal Film For Plastic Parameter Detection About Heat Sealing Performace

| Sealing Temp. | Ambient~300℃ | Deviation | ±0.2℃ |

|---|---|---|---|

| Sealing Time | 0.1S~9999S | Sealing Pressure | 0.15~0.7 MPa |

| Seal Jaws | 330*10 Mm L*W | Gas Pressure | 0.7 MPa |

| Port Size | Ф6 Mm PU Hose | Power | AC 220V 50Hz |

Heat Sealing Testing Machine By PID Control Heat Seal Film For Plastic Parameter Detection About Heat Sealing Performace

![]()

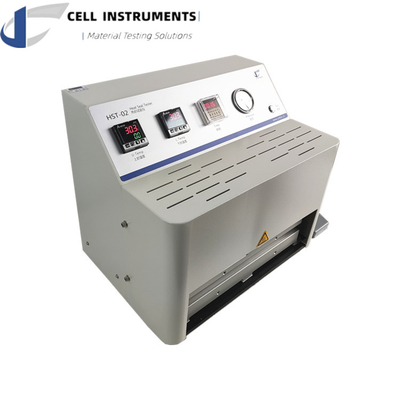

Introduction to HST-02 Heat Sealing Testing Machine

The HST-02 Heat Sealing Testing Machine, designed and manufactured by Cell Instruments, is an advanced laboratory instrument engineered to evaluate the heat sealability of various surfaces such as sealant layers in films, laminates, composites, and polymers. This state-of-the-art Heat Sealing Testing Machine offers precision in controlling key sealing parameters including temperature, pressure, and sealing time, which are essential for industries that work with thermoplastic materials.

The HST-02 Heat Sealing Testing Machine is ideal for quality control, research, and development applications in industries such as packaging, food, pharmaceuticals, and textiles. Its ability to precisely simulate real-world heat sealing conditions helps manufacturers ensure the reliability, durability, and strength of their heat-sealed products.

Key Features of the HST-02 Heat Sealing Testing Machine

The HST-02 Heat Sealing Testing Machine comes equipped with advanced features, making it an indispensable tool for various industries:

1. Aluminum Sealing Components for Temperature Stability

Both the upper and lower components of the heat sealing jaws are made from aluminum, ensuring minimal heat loss during sealing and providing excellent temperature uniformity. This feature is crucial for maintaining consistent and reliable sealing results during extended testing.

2. Precision P.I.D. Temperature Control

The HST-02 is integrated with a high-quality P.I.D. temperature controller, which allows for highly accurate temperature regulation during the sealing process. Precise temperature control ensures that the heat seal process is optimized, resulting in strong and consistent seals.

3. Synchronized Timer with Proximity Sensor

The synchronized operation of the timer and proximity sensor ensures precise timing of the seal process. The timing is critical in determining the strength of the heat seal, especially for industries that rely on standardized testing for quality assurance.

4. Three-Way Guided Sealing Bar for Uniform Pressure

The three-way guided sealing bar ensures consistent and uniform sealing pressure across the material. This feature is particularly important in achieving repeatable and reliable sealing results, even for challenging materials such as multi-layer laminates or thick films.

5. Safety Features for Enhanced User Protection

The HST-02 Heat Sealing Testing Machine comes equipped with built-in safety features such as an anti-scald front cover to prevent user injuries. Additionally, the machine offers both manual and foot-switch operation options, giving users flexibility in controlling the sealing process while ensuring a safe working environment.

Why You Need the HST-02 Heat Sealing Testing Machine

For industries that rely on the production and testing of thermoplastic materials, the HST-02 Heat Sealing Testing Machine is an essential tool for verifying the quality and performance of heat seals. The machine ensures precise control over key variables such as temperature, pressure, and time, all of which are crucial for producing effective and durable heat seals. Whether you’re testing flexible packaging for food products, pharmaceutical pouches, or other thermoplastic applications, this Heat Sealing Testing Machine is designed to provide reliable, repeatable results.

Purpose of the HST-02 Heat Sealing Testing Machine

The HST-02 Heat Sealing Testing Machine is primarily used to evaluate the heatsealability of various materials, including films, laminates, composites, and polymers. By simulating the heat-sealing process and controlling critical parameters such as time, temperature, and pressure, the machine helps users assess and optimize the quality of their heat seals. The resulting data from the tests can be used to improve product quality, enhance durability, and ensure compliance with industry standards.

Applications of the HST-02 Heat Sealing Testing Machine

The HST-02 Heat Sealing Testing Machine is suitable for a broad range of industries, including:

- Packaging: Ensuring the quality of seals in flexible packaging materials such as pouches, sachets, and bags.

- Food: Verifying the seal integrity of packaging materials used for food products to maintain freshness and safety.

- Pharmaceuticals: Testing heat-sealed pouches and blister packaging to ensure product protection.

- Textiles: Evaluating the performance of heat-sealed seams in protective clothing and industrial textiles.

- Paper: Assessing heat seal performance in paper-based packaging and laminates.

- Adhesives and Laminates: Testing the seal quality of adhesive films and multi-layer laminates.

In addition to industrial applications, the HST-02 Heat Sealing Testing Machine is widely used in research facilities, including universities, official laboratories, and enterprise R&D centers.

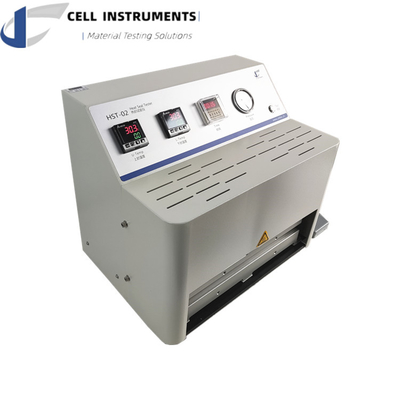

Technical Specifications of HST-02 Heat Sealing Testing Machine

| Parameter | Specification |

|---|---|

| Sealing Temperature | Ambient to 300°C |

| Temperature Deviation | ±0.2°C |

| Sealing Time | 0.1 to 9999 seconds |

| Sealing Pressure | 0.15 to 0.7 MPa |

| Sealing Jaw Dimensions | 330 x 10 mm (L x W) |

| Gas Pressure | 0.7 MPa |

| Port Size | Ф6 mm PU Hose |

| Power Supply | AC 220V, 50Hz |

Compliance with Industry Standards

The HST-02 Heat Sealing Testing Machine complies with ASTM F2029-16(2021), the recognized standard for making laboratory heat seals and determining the heat sealability of flexible barrier materials. This ensures that testing carried out on this machine meets globally accepted standards for seal strength and durability.

Why Choose the HST-02 Heat Sealing Testing Machine?

- Precision: The machine’s P.I.D. temperature control ensures the exact temperature needed for perfect seals.

- Consistency: The three-way guided sealing bar and proximity sensor deliver uniform pressure and consistent results.

- Versatility: Its wide temperature and pressure range allow testing of various materials, including films, laminates, and composites.

- Safety: Equipped with advanced safety features to protect the operator during testing.

- Ease of Use: Simple operation with both manual and foot-switch controls makes the machine user-friendly for laboratory technicians.

Frequently Asked Questions (FAQ)

Q: What industries can benefit from using the HST-02 Heat Sealing Testing Machine?

A: Industries such as packaging, food, pharmaceuticals, textiles, and adhesives will find the HST-02 indispensable for testing the seal strength of various materials.

Q: How does the HST-02 Heat Sealing Testing Machine ensure consistent test results?

A: The machine features precise temperature control, synchronized timing, and uniform pressure application, ensuring repeatable and accurate results.

Q: What safety features are included in the HST-02?

A: The machine is equipped with an anti-scald front cover and offers both manual and foot-switch operation to ensure safe and flexible usage.

Q: Can the HST-02 be used for testing multi-layer laminates?

A: Yes, the HST-02 is designed to handle various materials, including multi-layer laminates, ensuring reliable heat seals across different substrates.

Q: What industry standards does the HST-02 adhere to?

A: The machine complies with ASTM F2029-16(2021), ensuring that your testing procedures meet internationally recognized standards for heat sealing.

![]()