Plastic Packaging Quality Testing Machine About Heat Sealing In Laboratory Heat Sealing Analyzer For Medicine Package

| Sealing Temp. | Ambient~300℃ | Deviation | ±0.2℃ |

|---|---|---|---|

| Sealing Time | 0.1S~9999S | Sealing Pressure | 0.15~0.7 MPa |

| Seal Jaws | 330*10 Mm L*W | Gas Pressure | 0.7 MPa |

| Port Size | Ф6 Mm PU Hose | Power | AC 220V 50Hz |

Plastic Packaging Quality Testing Machine About Heat Sealing In Laboratory Heat Sealing Analyzer For Medicine Package

![]()

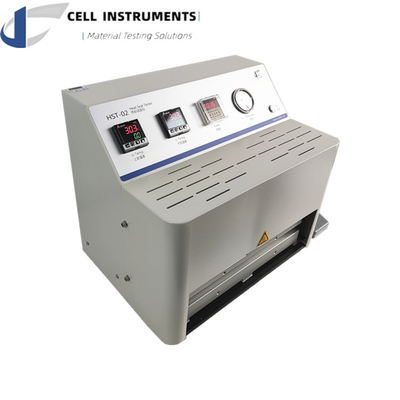

Introduction of HST-02 Heat Seal Tester

The HST-02 Heat Seal Tester by Cell Instruments is an advanced laboratory instrument, meticulously engineered for assessing the heatsealability of films, laminates, composites, polymers, and other thermoplastic materials. Heat sealing in laboratory environments is critical for industries that demand precision, especially in sectors like packaging, pharmaceuticals, and food manufacturing. This highly versatile and accurate machine offers complete control over sealing parameters such as time, temperature, and pressure, ensuring that your heat sealing tests yield reliable, consistent, and repeatable results.

What Makes the HST-02 Heat Seal Tester Stand Out?

The HST-02 Heat Seal Tester is an indispensable tool for heat sealing in laboratory settings. It’s particularly important for industries where material sealing quality can affect product longevity, safety, and performance. Whether in packaging, food, or pharmaceutical sectors, this equipment allows for in-depth testing to ensure the integrity of heat seals under a range of controlled conditions.

Technical Features of the HST-02 Heat Seal Tester

The HST-02 Heat Seal Tester includes a variety of cutting-edge features that ensure efficiency, stability, and safety in the heat sealing in laboratory processes:

-

Aluminum Components for Temperature Uniformity: Both upper and lower components are constructed from aluminum, which minimizes heat loss and ensures temperature consistency during the sealing process.

-

P.I.D. Temperature Controller: Featuring a state-of-the-art P.I.D. (Proportional Integral Derivative) temperature controller, the HST-02 enables precise regulation of heating, which is critical for achieving optimal sealing results.

-

Synchronized Timer and Proximity Sensor: This ensures that the timing of the seal coincides with jaw movement, thereby enhancing the consistency and repeatability of the sealing tests.

-

Three-Way Guided Sealing Bar: This design element ensures that pressure is evenly distributed, resulting in high-quality, reliable seals across a wide range of material types.

-

Safety Features: Safety is a key design aspect of the HST-02 Heat Seal Tester, including an anti-scald front cover, manual and foot switch initiation, and additional safeguards to protect users during testing procedures.

The Importance of Heat Sealing in Laboratory Environments

In heat sealing in laboratory environments, the accuracy and reliability of your heat seal testing can make or break the quality of the product. The HST-02 Heat Seal Tester is designed to simulate real-world conditions and offers unparalleled precision in controlling critical parameters like time, temperature, and pressure. This makes it an ideal tool for quality assurance and research in industries such as packaging, food, and medicine.

Key Applications of the HST-02 Heat Seal Tester

The HST-02 Heat Seal Tester is used in a wide range of industries that rely on heat sealing to ensure product quality, safety, and durability. Some common sectors where the HST-02 is indispensable include:

-

Pharmaceutical Packaging: Ensuring that heat seals on medical packaging are secure and meet regulatory standards.

-

Food Packaging: Maintaining product freshness by testing the effectiveness of seals in plastic wraps, films, and laminates.

-

Cosmetic and Toiletry Packaging: Verifying that heat-sealed packaging remains intact during shipping and storage.

-

Textiles and Adhesives: Testing seals on flexible and composite materials used in various industrial applications.

-

Official Laboratories and Research Institutions: The HST-02 Heat Seal Tester is widely used for academic research and quality testing in laboratories across universities, colleges, and regulatory bodies.

What Problems Does the HST-02 Solve?

The primary function of the HST-02 Heat Seal Tester is to solve critical problems related to heat sealing in laboratory settings. Whether you're in packaging, pharmaceutical, or food processing industries, poor heat sealing can lead to product degradation, contamination, or failure. By offering precise control over sealing parameters and replicating real-world sealing conditions, the HST-02 helps businesses identify weak points in their heat sealing processes and rectify them before products reach consumers.

Main Technical Parameters of the HST-02 Heat Seal Tester

| Sealing Temp. | Ambient~300℃ |

| Deviation | ±0.2℃ |

| Sealing Time | 0.1S~9999S |

| Sealing Pressure | 0.15~0.7 MPa |

| Seal Jaws | 330*10 mm L*W |

| Gas Pressure | 0.7 MPa |

| Port Size | Ф6 mm PU Hose |

| Power | AC 220V 50Hz |

Standards Compliance

The HST-02 Heat Seal Tester adheres to the ASTM F2029-16(2021) Standard Practices for Making Laboratory Heat Seals for Determination of Heat Sealability of Flexible Barrier Materials as Measured by Seal Strength. This ensures that all testing results meet the highest industry standards and can be confidently applied in quality control and research settings.

Why Choose the HST-02 for Heat Sealing in Laboratory Testing?

When it comes to heat sealing in laboratory environments, precision and reliability are paramount. The HST-02 is designed to provide just that, offering users unmatched control over the heat sealing process. Its compact design, user-friendly interface, and high level of safety features make it an ideal choice for businesses looking to improve the quality and durability of their heat seals.

Frequently Asked Questions (FAQs)

Q: What types of materials can be tested using the HST-02 Heat Seal Tester?

A: The HST-02 is versatile and can test a range of thermoplastic materials, including films, laminates, composites, and polymer-based packaging materials.

Q: How does the HST-02 ensure consistent sealing pressure?

A: The HST-02 uses a three-way guided sealing bar that distributes pressure evenly across the seal, ensuring high-quality and reliable heat seals.

Q: Is the HST-02 suitable for research purposes?

A: Absolutely. The HST-02 Heat Seal Tester is widely used in both industrial and academic research settings due to its precision and control over sealing parameters.

Q: Can the HST-02 be used for quality control in food packaging?

A: Yes, the HST-02 is ideal for testing seals in food packaging to ensure they maintain product integrity and safety.

Q: How does the HST-02 comply with safety standards?

A: The HST-02 includes an anti-scald front cover, along with manual and foot switch initiation options, ensuring user safety during testing procedures.

![]()