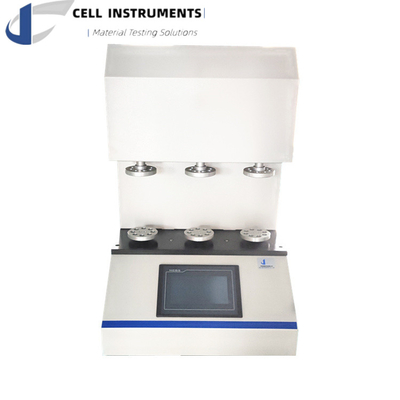

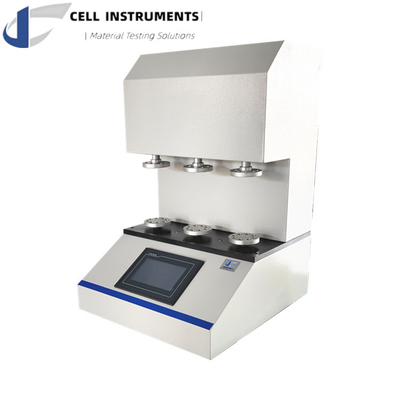

Gelbo Flex Testing Machine For Transparent Barrier Food Packaging Film ASTM F392 Lab Testing Equipment

| Flex Frequency | 45 /minute | Flex Angle | 440° (90 Mm) Or 400° (80 Mm) |

|---|---|---|---|

| Capacity | 3.5 N.m | Horizontal Stroke | 155 Mm Or 80 Mm |

| Stations | 3 | Sample Size | 280 Mm X 200 Mm |

| Power | 110~220V |

Gelbo Flex Testing Machine For Transparent Barrier Food Packaging Film ASTM F392 Lab Testing Equipment

![]()

Introduction to Gelbo Flex Testing Machine

The Gelbo Flex Testing Machine is a highly specialized piece of laboratory equipment designed to assess the durability of flexible barrier materials under repetitive strain. This critical testing device plays a vital role in industries where packaging integrity is paramount, such as food, pharmaceuticals, and medical supplies. Ensuring that packaging materials, such as films and composites, can withstand continuous bending, twisting, and compression is essential to avoid packaging failures during shipping and storage. The GFT-02 Gelbo Flex Testing Machine is the ideal solution for manufacturers seeking to evaluate the flex durability of their products, providing reliable and precise results in line with ASTM F392 standards.

Why Flex Durability is Important?

The ability of flexible packaging materials to endure repetitive strain—referred to as Gelbo Flex Resistance—is crucial for maintaining the integrity of packaged goods during transportation. Packaging materials that fail to pass the Gelbo Flex Testing Machine evaluation are prone to developing cracks, pinholes, and other defects that can lead to contamination or spoilage of the contents. By simulating real-world flexing and twisting conditions, the Gelbo Flex Testing Machine helps manufacturers reduce the risk of packaging failures, ensuring that products arrive intact at their destination.

Key Applications of the Gelbo Flex Testing Machine

The Gelbo Flex Testing Machine is widely used across multiple industries, including:

- Food Packaging: Ensuring flexible packaging materials maintain their barrier properties during the distribution process.

- Pharmaceutical Packaging: Testing the flex resistance of medical packaging to prevent contamination.

- Cosmetics: Evaluating the durability of flexible containers and pouches.

- Textiles and Composites: Ensuring that flexible materials can withstand repetitive use without compromising strength.

- Adhesive Products: Testing the flex durability of adhesive-backed films used in industrial applications.

By identifying weak points in packaging films and laminates, the Gelbo Flex Testing Machine contributes significantly to improving packaging performance across these industries.

Gelbo Flex Testing Machine – Detailed Working Process

The Gelbo Flex Testing Machine operates by subjecting packaging materials to a combination of twisting and compression motions, replicating the real-world conditions they would face during distribution. The test sample is attached to mandrels within the testing chamber and exposed to various cycles of flexing. The machine's ability to perform both long-stroke and short-stroke flexing tests ensures comprehensive evaluation of the material’s resistance to flex fatigue.

Testing Procedure:

- Sample Setup: A film sample of 200 x 280 mm is placed between two mandrels.

- Flexing Motion: The machine initiates a twisting motion at an angle of 440°, covering a 90 mm stroke length. Simultaneously, the material undergoes a 65 mm horizontal compression, simulating real-world strain.

- Cycle Speed: Each cycle occurs at a rate of 45 cycles per minute.

- Pre-Programmed Modes: The tester allows users to select from five test modes, offering flexibility in testing duration and intensity. These include:

- Mode A: Full flex for 1 hour (2,700 cycles).

- Mode B: Full flex for 20 minutes (900 cycles).

- Mode C: Full flex for 6 minutes (270 cycles).

- Mode D: Full flex for 20 cycles.

- Mode E: Partial flex for 20 cycles.

ASTM F392 Compliance

The Gelbo Flex Testing Machine is fully compliant with the ASTM F392 standard, which defines the methodology for assessing the flex durability of flexible barrier materials. Adherence to this standard ensures that test results are reliable and reproducible, giving manufacturers confidence in their product’s ability to withstand rigorous distribution environments.

Technical Specifications of Gelbo Flex Testing Machine (GFT-02)

- Flex Frequency: 45 cycles per minute.

- Flex Angle: 440° for long stroke (90 mm), 400° for short stroke (80 mm).

- Capacity: 3.5 N.m.

- Horizontal Stroke: 155 mm (long stroke), 80 mm (short stroke).

- Stations: 3 test stations for simultaneous testing.

- Sample Size: 280 x 200 mm.

- Power Supply: 110~220V adaptable for global use.

Advanced Features and User-Friendly Interface

The Gelbo Flex Testing Machine incorporates advanced PLC control with an intuitive HMI touch screen interface, making it easy to operate. With five pre-programmed test modes, users can quickly set up tests based on the specific requirements of their materials. Additionally, the device allows for quick switching between long-stroke and short-stroke flex tests, providing versatility and accuracy in testing.

Key Benefits of the Gelbo Flex Testing Machine

- Ensures Packaging Durability: By subjecting materials to realistic flex conditions, the Gelbo Flex Testing Machine helps ensure that packaging can withstand the rigors of transportation and handling.

- Improves Product Safety: With accurate testing, manufacturers can minimize the risk of packaging failures, reducing the likelihood of product contamination or damage.

- Increases Efficiency: With three testing stations and fast cycle times, the Gelbo Flex Testing Machine can process multiple samples simultaneously, improving throughput.

- User-Friendly Operation: The PLC-controlled system, combined with a touch-screen interface, simplifies the testing process, allowing operators to easily manage test parameters and monitor results.

Industries That Benefit from Gelbo Flex Testing

The Gelbo Flex Testing Machine is indispensable for companies involved in the production of packaging films, medical devices, food packaging, and textiles. Its ability to test the flex resistance of various materials ensures that products remain safe and intact throughout the supply chain. This testing machine is ideal for:

- Food and Beverage Manufacturers: Ensuring that flexible packaging materials maintain their integrity during storage and transport.

- Pharmaceutical Companies: Testing the durability of packaging materials used for medical products.

- Consumer Goods: Ensuring flexible packaging meets durability standards in industries such as personal care and cosmetics.

Frequently Asked Questions (FAQ)

Q1: What type of materials can be tested with the Gelbo Flex Testing Machine?

A1: The Gelbo Flex Testing Machine is suitable for testing a variety of flexible barrier materials, including packaging films, laminates, composites, and coatings.

Q2: How does the Gelbo Flex Testing Machine ensure accurate results?

A2: The machine uses a combination of twisting and horizontal compression motions to simulate real-world conditions. The adherence to ASTM F392 standards ensures test accuracy and repeatability.

Q3: Is the machine suitable for high-volume testing?

A3: Yes, the GFT-02 Gelbo Flex Testing Machine features three test stations and can perform up to 45 cycles per minute, making it ideal for high-throughput environments.

Q4: Can the test parameters be customized?

A4: The Gelbo Flex Testing Machine offers five pre-programmed test modes, allowing users to select the most appropriate conditions for their testing needs.

Q5: What industries commonly use the Gelbo Flex Testing Machine?

A5: Industries that benefit from this machine include food packaging, pharmaceuticals, textiles, medical device manufacturers, and more.

![]()