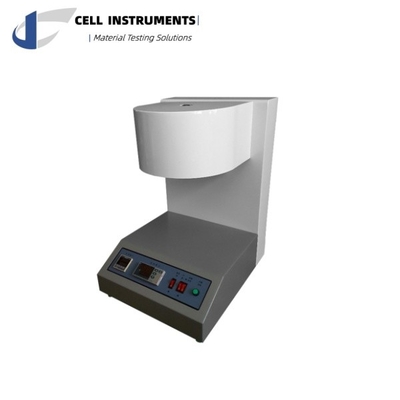

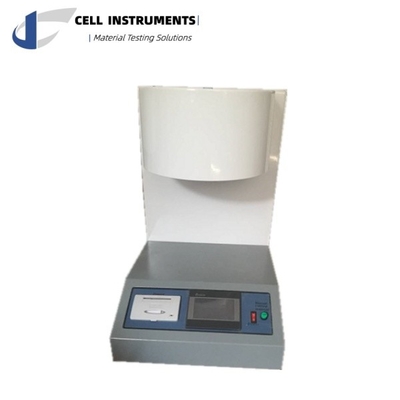

Melt Flow Rate Testing Meter For Plastic And Resin In In Viscous Flow State

| Measuring Range(MFR) | 0.1-400.00g/10min | Temperature Range | Ambient~450°C |

|---|---|---|---|

| Cylinder Internal Diameter | 9.550mm ± 0.025mm | Cylinder Length | 160mm |

| Power Supply | AC220V, 50Hz | Dimensions | 400mm×500mm×600mm |

Melt Flow Rate Testing Meter For Plastic And Resin In In Viscous Flow State

![]()

Melt Flow Rate Testing (MFR) is a critical procedure for evaluating the viscosity and flow behavior of thermoplastic materials under specific temperature and load conditions. This type of testing is fundamental to understanding the quality and performance of plastics and resins used across various industries, including packaging, pharmaceuticals, food, beverages, and academic research. The RZ-A Melt Flow Rate Tester is a state-of-the-art instrument designed for precise and reliable Melt Flow Rate Testing, offering highly accurate results that comply with international standards. This cutting-edge instrument is essential for material quality control, making it an indispensable tool for manufacturers and quality inspection labs.

Introduction of the RZ-A Melt Flow Rate Tester

The RZ-A Melt Flow Rate Tester is designed to meet the demanding needs of both research and industry. Featuring intelligent temperature control and dual-position time relay output, this equipment ensures optimal performance for precise Melt Flow Rate Testing. With its rapid heating capabilities, high accuracy, and ease of use, this tester is suitable for laboratories, manufacturing enterprises, and academic institutions that require consistent and repeatable MFR test results.

This Melt Flow Rate Testing meter excels in measuring the flow properties of various plastics and resins in their viscous flow state, making it highly relevant for companies working with thermoplastic materials. The advanced design ensures that the tester maintains a short constant temperature cycle, minimizing temperature overshooting and enhancing the accuracy and stability of the testing process.

Key Features of the RZ-A Melt Flow Rate Tester

- PID temperature controller and dibit time relay control system: These features allow for precise control over testing conditions, ensuring that temperature stability is maintained throughout the Melt Flow Rate Testing process.

- Dual cutting modes: The instrument supports both timed and manual cutting methods, allowing for customizable intervals and times to suit a variety of testing needs.

- High-efficiency heating: The RZ-A can quickly reach the desired temperature, reducing downtime and increasing the efficiency of the testing process.

- Stable and accurate performance: This tester offers high precision in measuring melt flow rates, delivering reliable results that can be trusted for critical decision-making in quality control.

These features make the RZ-A an ideal instrument for plastic raw material manufacturers, plastic product producers, and research institutions that prioritize accuracy and efficiency in their Melt Flow Rate Testing procedures.

Comprehensive Technical Specifications

The RZ-A Melt Flow Rate Tester is designed to meet a wide range of testing requirements. Below are its key technical parameters:

| Items | Parameters | ||||

| Models | RZ-A | RZ-B | RZ-W | RZ-C | RZ-H |

| Method | MFR | MFR&MVR | |||

| Control/Display | LED | PLC, touch Screen | PC, Touch Screen, PLC | PLC, Touch Screen | |

| Software | N/A | Yes | N/A | ||

| Micro Printer | N/A | N/A | Yes | ||

| Measuring Range/10min | 0.1-400g | 0.1-800g(MFR) 0.1-800cm³(MVR) |

0.1-3000g(MFR) 0.1-3000cm³(MVR) |

(0.01~200)g(MFR) (0.1~2500)cm³(MVR) |

|

| Temperature Range | Ambient~450°C | ||||

| Temp. Precision | ±0.2°C | ±0.5°C | ±0.2°C | ||

| Time Accuracy | 1S or 0.01S | 0.1S | |||

| Disp. Precision | 0.01mm | ||||

| Load | Full Load 0.325~21.6kg | ||||

| Cutting Mode | Manual, Time | Time; Auto | Time; Auto | ||

| Cylinder Diameter | 9.550mm ± 0.025mm | ||||

| Cylinder Length | 160mm | ||||

| Die | Tungsten Carbide, L8.000mm ± 0.025mm, Internal Diameter 2.095mm ± 0.005mm | ||||

| Power | 0.45 KW | 0.5 KW | 0.45 KW | ||

| Power Supply | AC220V, 50Hz | ||||

Applications of Melt Flow Rate Testing

Melt Flow Rate Testing is crucial in determining the processing behavior of thermoplastics. This test is widely used in industries such as packaging, pharmaceuticals, food, and beverages. By understanding the flow properties of materials under controlled temperature and load, manufacturers can optimize production processes, ensure consistent product quality, and meet regulatory standards. The RZ-A Melt Flow Rate Tester is particularly well-suited for applications involving polyethylene (PE), polypropylene (PP), polystyrene (PS), and other thermoplastics.

For manufacturers of plastic products, quality control is critical to maintaining product consistency. The Melt Flow Rate Testing provided by the RZ-A helps ensure that the materials meet the required performance standards, whether for packaging films, plastic containers, or medical devices. The data obtained from this tester allows engineers and researchers to fine-tune material formulations, ensuring that the final products meet customer specifications.

Why Choose the RZ-A Melt Flow Rate Tester?

- Unmatched Accuracy: With its PID temperature controller and precise load control, the RZ-A provides highly accurate results, ensuring that your Melt Flow Rate Testing is reliable and repeatable.

- Ease of Use: The user-friendly design, combined with customizable testing options, makes this instrument easy to operate, even for users with limited experience in Melt Flow Rate Testing.

- Durability and Stability: Built with high-quality materials, including tungsten carbide for critical components, this tester offers long-lasting durability and stable performance, even in high-use environments.

- Versatility: The wide range of test parameters makes the RZ-A suitable for a variety of materials and industries, from packaging to pharmaceuticals.

Compliance with International Standards

The RZ-A Melt Flow Rate Tester complies with key international standards for Melt Flow Rate Testing, ensuring that test results are consistent with global quality benchmarks. Compliance with these standards is essential for companies that produce or import thermoplastic materials in regulated markets. The tester can also be used for research and development purposes, where precise material characterization is required.

Industries That Benefit from Melt Flow Rate Testing

- Packaging: Melt Flow Rate Testing helps determine the performance of plastic films and containers used in food, beverage, and medical packaging.

- Pharmaceuticals: Ensuring that plastic materials used in medical devices and packaging meet quality standards is critical for safety and regulatory compliance.

- Food & Beverage: Plastics used in food storage and packaging must meet stringent quality requirements, and Melt Flow Rate Testing ensures that these materials perform as expected.

- Academic Institutions: Research laboratories use the RZ-A to study material properties, ensuring that their findings are backed by precise and reliable data.

![]()

![]()