ISO 534 Paper Thickness gauge Tester High Precise Digital Paper contact Thickness measurement Testing Equipment

| Test Range | 0~2mm(Customization Available) | Resolution | 0.1 μm |

|---|---|---|---|

| Standard Measure Head | Hemispherical Type | Optional Measure Head (flat Foot) | 50 Mm² , 17.5±1 KPa (for Film)/200 Mm² , 50±1 KPa (for Paper) |

| Power | AC 110~220V |

ISO 534 Paper Thickness gauge Tester High Precise Digital Paper contact Thickness measurement Testing Equipment

![]()

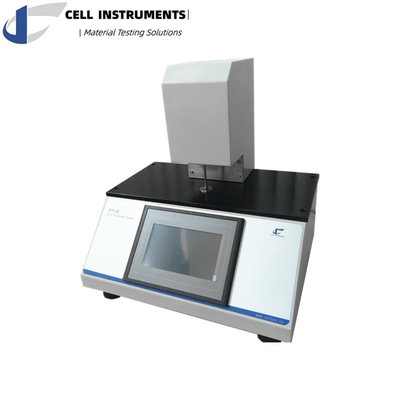

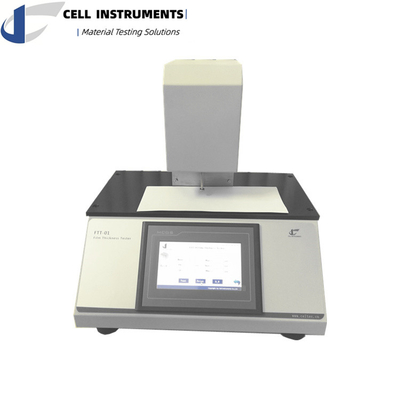

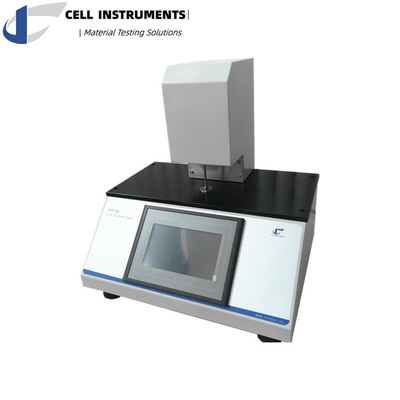

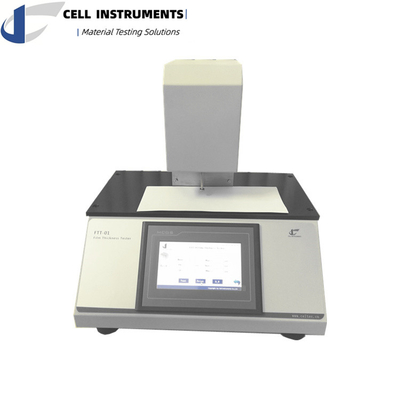

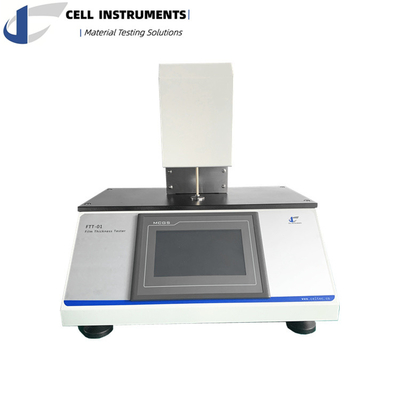

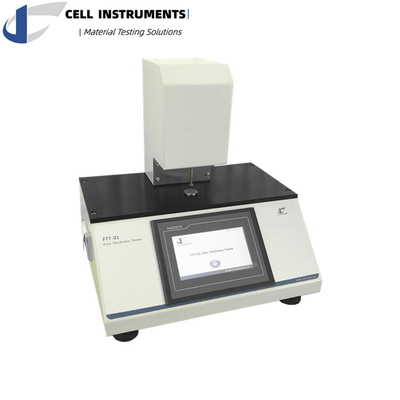

The FTT-01 Film Thickness Testing Machine from Cell Instruments is a cutting-edge solution designed for accurate and reliable measurement of film thickness across a variety of materials. This advanced instrument is ideal for use in laboratories across industries such as packaging, food, medicine, and beverages. It ensures precise thickness testing and complies with various international standards, making it a valuable asset for quality control and material assessment.

Introduction to the FTT-01 Film Thickness Testing Machine

The FTT-01 Film Thickness Testing Machine offers high precision and stability in thickness measurement. Controlled by a sophisticated Programmable Logic Controller (PLC) and operated through an intuitive Human-Machine Interface (HMI) touch screen, this machine simplifies the testing process and enhances accuracy. The FTT-01 utilizes a mechanical scanning method to measure thickness, making it suitable for a wide range of materials, including plastic films, metal sheets, textiles, and paper.

Key Advantages of the FTT-01 Film Thickness Testing Machine

-

Advanced PLC Control and HMI Touch Screen Operation: The FTT-01 Film Thickness Testing Machine features a PLC control system that provides high stability and precision. The HMI touch screen interface ensures user-friendly operation and efficient testing processes.

-

Automatic Presser Foot Lifting: This feature streamlines the testing process by automatically lifting the presser foot, ensuring consistent and accurate thickness measurements.

-

Real-Time Data Display: The machine offers real-time displays of maximum, minimum, average, and standard deviation measurements, allowing for immediate analysis and quality control.

-

Comprehensive Test Result Storage and Micro Printing: The FTT-01 includes capabilities for storing test results and micro printing, which enhances documentation and record-keeping.

-

Optional RS232 Port and Software Integration: The inclusion of an RS232 port supports connectivity with optional software for advanced data analysis and reporting.

-

Versatile Sample Feeding Options: The FTT-01 Film Thickness Testing Machine accommodates both manual and automatic sample feeding, providing flexibility to meet diverse testing needs.

Why You Need the FTT-01 Film Thickness Testing Machine

-

Ensures Product Quality Assurance: The FTT-01 Film Thickness Testing Machine helps maintain consistent film thickness, preventing defects such as uneven appearance and poor performance.

-

Optimizes Cost Control: By optimizing material usage, this machine helps reduce production costs associated with excessive material consumption.

-

Guarantees Regulatory Compliance: The FTT-01 meets industry standards, particularly in food packaging and medical devices, ensuring compliance with thickness requirements for safety and performance.

-

Facilitates Process Optimization: The machine acts as an indicator of a well-controlled manufacturing process, allowing for the identification and correction of deviations or equipment issues.

-

Enhances Material Efficiency: By optimizing thickness, the FTT-01 ensures efficient use of material resources, reducing waste.

-

Boosts Customer Satisfaction: Meeting specific product dimensions and performance characteristics enhances customer satisfaction and encourages repeat business.

Purpose of the FTT-01 Film Thickness Testing Machine

- Ensuring Product Quality and Consistency: Achieve precise and consistent thickness measurements.

- Facilitating Cost Control: Optimize material usage and reduce costs.

- Guaranteeing Regulatory Compliance: Meet strict industry standards for thickness.

- Enabling Process Control and Optimization: Monitor and improve manufacturing processes.

- Enhancing Material Efficiency: Reduce waste and optimize material usage.

- Meeting Customer Expectations: Deliver products that meet exact specifications and performance standards.

Applications

The FTT-01 Film Thickness Testing Machine is versatile and can measure the thickness of a wide range of materials, including:

- Plastic films

- Metal sheets

- Fabrics

- Textiles

- Membranes

- Paper

- Foil

- Wafers

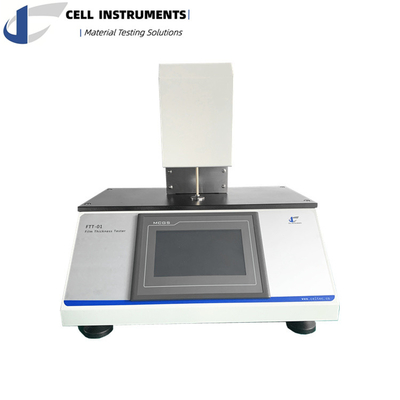

Specifications

| Test Range | 0~2mm(Customization available) |

| Resolution | 0.1 μm |

| Standard Measure Head | Hemispherical type |

| Optional Measure Head (flat foot) | 50 mm² , 17.5±1 KPa (for film) 200 mm² , 50±1 KPa (for paper) |

| Power | AC 110~220V |

Standards Compliance

The FTT-01 Film Thickness Testing Machine adheres to several international standards, ensuring precision and reliability, including:

- ASTM D374-99: Standard Test Methods for Thickness of Solid Electrical Insulation

- ASTM D1777: Standard Test Method for Thickness of Textile Materials

- ISO 3034:2011: Corrugated Fiberboard - Determination of Single Sheet Thickness

- ISO 534-2011: Paper and Board - Determination of Thickness, Density, and Specific Volume

- ISO 4593: Plastics - Film and Sheeting - Determination of Thickness by Mechanical Scanning

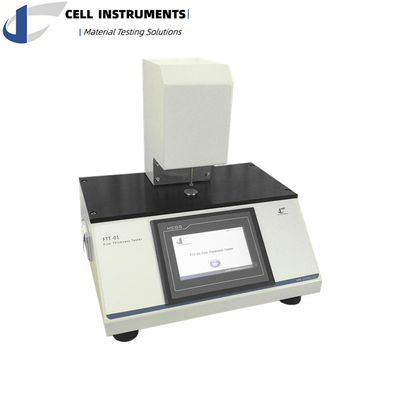

Technical Features

- PLC and HMI Control: Advanced control systems for precision and ease of use.

- Automatic Presser Foot Lifting: For consistent and accurate measurements.

- Real-Time Data Display: Immediate analysis of measurement data.

- Test Result Storage and Micro Printing: Detailed documentation capabilities.

- RS232 Port and Software Compatibility: For extended data analysis.

- Manual and Automatic Sample Feeding: Flexible testing options.

The FTT-01 Film Thickness Testing Machine is a premier instrument for accurate thickness measurement, contributing to improved product quality, cost efficiency, regulatory compliance, and process control across various industries.

![]()