Leak Tester Blister Leakage Tester ASTM D3078 Vacuum Leak Tester Food Sachet Water Bubble Leak Tester

| Power | 110~220V | Brand | CELL INSTRUMENTS |

|---|---|---|---|

| Highlight | leakage,leak detector,leakage tester |

||

Leak Tester Blister Leakage Tester ASTM D3078 Vacuum Leak Tester Food Sachet Water Bubble Leak Tester

| LT-03 | |

| Test Range | 0~-90 KPa |

| Chamber | Acrylic Cylinder Shape |

| Test Space | Φ270*H210mm (Inside Usable) |

| Compressed Air | 0.7MPa (Prepared by user) |

| Power | 110~220V 50/60Hz |

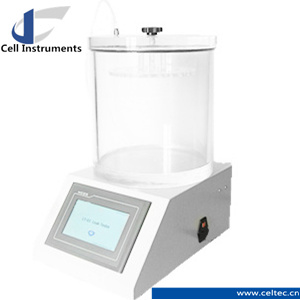

The Leak Tester is a critical instrument designed to examine the airproof property of various packaging materials, containers, bags, and pipes. Our LT-03 package airproof Leak Tester provides accurate and reliable results, making it an essential tool for industries that require precise leak detection, including food, beverage, pharmaceutical, daily chemical, electrical, and electronics. Complying with globally recognized standards such as ASTM D3078 and GB/T 15171, this Leak Tester ensures that products meet the highest quality and safety standards.

Applications of Leak Tester

The Leak Tester is versatile and can be applied in multiple industries:

- Food Industry: Ensures the safety and preservation of products by identifying leaks in food sachets, pouches, and packaging materials. Leak testing is crucial to maintaining freshness and preventing contamination.

- Beverage Industry: Detects leaks in beverage containers, bottles, and caps, ensuring that packaging is secure, avoiding spoilage or loss of carbonation.

- Pharmaceutical Industry: Critical for leak testing of pharmaceutical containers and blister packs, safeguarding product sterility and ensuring that the packaging remains intact.

- Daily Chemical Industry: Prevents leakage of daily chemical products such as shampoos, detergents, and lotions, maintaining product quality and consumer satisfaction.

- Electrical & Electronics: Ensures that electronic components and devices are protected from environmental factors like moisture, preventing damage and ensuring product longevity.

How the Leak Tester Works

The Leak Tester consists of two main parts: the mainframe and the vacuum chamber. The process is simple but highly effective:

- Sample Placement: The test sample (such as a sachet, blister pack, or container) is placed into the vacuum chamber filled with water.

- Vacuum Process: The air above the water level is evacuated using a venturi vacuum ejector, creating a pressure difference between the inside and outside of the sample.

- Leak Detection: If the sample is not airproof, it will inflate, and a stream of bubbles will indicate leakage. This visual confirmation provides quick and clear identification of compromised packaging.

- Automatic Control: The entire testing process is automatic, minimizing human error and ensuring consistent and accurate results.

Key Features of Leak Tester

Our LT-03 Leak Tester offers advanced features to enhance efficiency and accuracy:

- Fully Automatic Leak Testing Process: The entire leak test is performed automatically, streamlining operations and reducing manual intervention.

- User-Friendly Touchscreen Operation: With an intuitive touchscreen interface, operators can easily control the testing process and adjust parameters.

- Digital Vacuum Control: The vacuum degree and test time can be precisely inputted, ensuring accurate results tailored to specific testing requirements.

- Data Logging and Analysis: The system automatically saves test parameters and results, allowing for easy data retrieval and analysis for quality control purposes.

- Vacuum Maintenance and Air Back-Flushing: Automatically maintains the vacuum during the test, with a back-flushing feature that safely releases air after testing.

- Durable Design: The vacuum chamber is made of extra-thick Perspex, ensuring durability and resistance to wear and tear.

- Customizable Chamber Sizes: Various chamber sizes are available to accommodate different sample sizes, making the Leak Tester adaptable to a wide range of packaging and container types.

- No External Vacuum Pump Required: The built-in venturi vacuum system eliminates the need for a bulky external vacuum pump, reducing space requirements and simplifying operation.

- Low Maintenance: The Leak Tester is designed for easy operation and maintenance, making it a practical choice for laboratories and production lines.

Technical Specifications of Leak Tester

- Vacuum Range: 0 ~ -90KPa / 0 ~ -13 PSI

- Test Space Dimensions: Φ270 mm x 210 mm (H) (Customizable)

- Gas Source: Compressed air

- Gas Pressure: 0.7MPa / 101.5 PSI

- Standards: ASTM D3078, GB/T 15171

The flexibility of the Leak Tester makes it suitable for a wide range of testing scenarios. Whether you need to test the integrity of small sachets or large containers, the customizable chamber sizes and versatile vacuum range make this instrument ideal for both research and production environments.

Why Choose Our Leak Tester?

- Compliance with International Standards: The Leak Tester complies with ASTM D3078 and GB/T 15171, ensuring that your products meet the highest international safety and quality standards.

- Wide Industry Applications: The Leak Tester is trusted by businesses across various industries including food, beverage, pharmaceuticals, chemicals, and electronics.

- High Accuracy and Efficiency: The automatic testing process, combined with digital controls, ensures precise and repeatable results, minimizing the risk of undetected leaks.

- Durable and Reliable: Built with high-quality materials and designed for continuous use, the Leak Tester delivers long-lasting performance with minimal maintenance.

- Customizable Solutions: With various chamber sizes and adaptable features, the Leak Tester can be tailored to meet your specific testing needs.

Industry Standards Compliance: ASTM D3078 and GB/T 15171

The Leak Tester complies with two critical standards:

- ASTM D3078: This standard outlines the testing method for detecting gross leaks in packaging through the bubble emission method. It's particularly useful for testing flexible packaging in the food, pharmaceutical, and daily chemical industries.

- GB/T 15171: The Chinese equivalent to ASTM D3078, providing guidelines for leak testing in various types of packaging.

By adhering to these standards, our Leak Tester helps businesses ensure that their packaging is safe, airproof, and compliant with regulatory requirements.

![]()

![]()