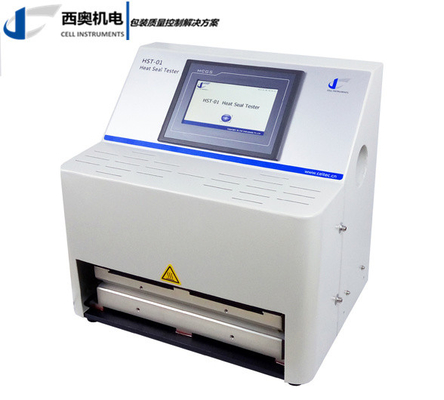

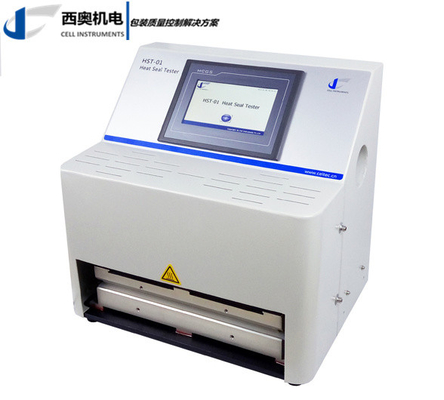

Aseptic Bag Heat Seal Tester Heat Sealer For Lab Use

| Power | Electronic | Usage | Plastic Testing Machine |

|---|

Aseptic Bag Heat Seal Tester Heat Sealer For Lab Use

Main Parameter

| Sealing Temp. | Ambient~300℃ |

| Deviation | ±0.2℃ |

| Sealing Time | 0.1S~9999S |

| Sealing Pressure | 0.15~0.7 MPa |

| Seal Jaws | 330*10 mm L*W |

| Gas Pressure | 0.7 MPa |

| Port Size | Ф6 mm PU Hose |

| Power | AC 220V 50Hz |

![]()

The Aseptic Bag Heat Seal Tester is an advanced laboratory instrument designed to simulate the heat sealing process utilized in the production of aseptic bags and other packaging materials. This essential testing device is tailored to determine the heat sealability of various surfaces and sealant layers, including films, laminates, composites, and polymers. It ensures that packaging meets industry standards for quality and safety, making it a crucial tool for manufacturers in the food, beverage, pharmaceutical, and packaging industries.

The Aseptic Bag Heat Seal Tester adheres to the stringent ASTM F2029 standard, providing reliable and consistent results for all heat sealing tests. With its precision engineering and advanced features, this tester is a must-have for laboratories focused on ensuring optimal sealing performance in their products.

Key Technical Features

-

Precision Temperature Control: The Aseptic Bag Heat Seal Tester employs a Proportional-Integral-Derivative (PID) controller for precise sealing temperature management. This feature guarantees that each test is performed at the exact temperature required for effective sealing.

-

Uniform Heating: The aluminum encapsulated sealing jaws are designed to deliver uniform heating across the sealing surface, eliminating inhomogeneous heating and ensuring consistent seal quality.

-

Accurate Timing Control: With a precise timer, the Aseptic Bag Heat Seal Tester ensures accurate control over sealing time, ranging from 0.1 seconds to 9999 hours. This allows for thorough testing under various conditions.

-

Independent Jaw Heating: The upper and lower sealing jaws can be heated independently, enabling customization for different materials and thicknesses, thus enhancing testing versatility.

-

Customizable Sealing Jaws: Users can request custom dimensions, shapes, and surface finishes for the sealing jaws to accommodate specific testing needs.

-

User-Friendly Operation: The device features both manual and foot switch options for starting tests, along with an anti-scald design to enhance user safety.

Technical Specifications

- Sealing Temperature: Room Temperature to 300°C

- Temperature Deviation: ±0.2°C

- Sealing Time: 0.1 seconds to 9999 hours

- Sealing Pressure: 0.15 MPa to 0.7 MPa

- Seal Jaw Dimensions: 330 mm × 10 mm (Customizable)

- Gas Pressure: 0.5 MPa to 0.7 MPa

- Port Size: Ф6 mm PU Hose

- Dimensions: 455 mm (L) × 320 mm (W) × 440 mm (H)

- Power Supply: AC 220V, 50Hz (Customization available)

Applications of the Aseptic Bag Heat Seal Tester

The Aseptic Bag Heat Seal Tester is widely used across various industries, including:

- Food Industry: Ensuring the integrity of packaging materials that preserve food quality and safety.

- Beverage Industry: Testing the seals of beverage pouches and bags to prevent leakage and spoilage.

- Pharmaceutical Industry: Validating the sealing properties of aseptic packaging for medical products to maintain sterility.

- Packaging Sector: Offering reliable testing solutions for manufacturers aiming to meet regulatory and quality standards.

Why Choose the Aseptic Bag Heat Seal Tester?

Investing in the Aseptic Bag Heat Seal Tester means committing to quality assurance and safety in your products. This state-of-the-art testing instrument helps you identify potential weaknesses in your packaging, ensuring that your products reach consumers in optimal condition. Its robust design, combined with user-friendly features, makes it an essential tool for laboratories striving for excellence in material testing.

By incorporating the Aseptic Bag Heat Seal Tester into your testing protocol, you will enhance your product development process and improve customer satisfaction through reliable and high-quality packaging solutions.

![]()