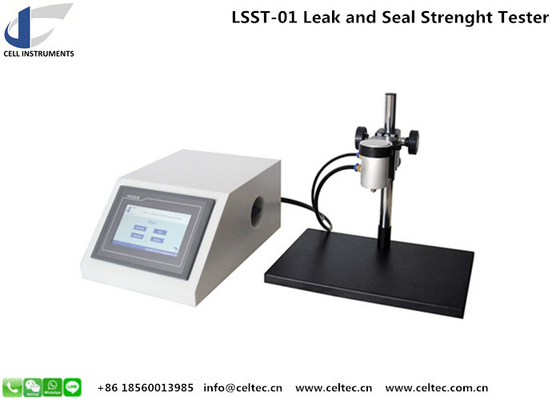

ASTM F2054 ASTM F1140 Flexible package burst tester pressure decay burst tester

| Power | 110~220V | Usage | Plastic Testing Machine |

|---|---|---|---|

| Warranty | 12 Months | Test Range | 0~600KPa |

| Sample Width | 300mm (standard) | Inflating Head | Φ4mm |

Burst Tester for Evaluating Package Integrity

Application

he ASTM F2054 and ASTM F1140 compliant burst tester is an indispensable tool for assessing the integrity of flexible packaging through pressure decay leak testing. Designed to ensure the delivery of optimal product protection, this tester evaluates the seal integrity of various packaging solutions across industries such as packaging, food, medicine, beverage, and academia.

Test Method: Utilizing the pressure decay method, this advanced tester pressurizes the sample to a predetermined level, sealing the air source to monitor any subsequent pressure reduction. By detecting deviations in pressure, it identifies potential leaks, enabling thorough evaluations of packaging performance. The burst tester offers comprehensive analysis through burst testing, creep testing, and creep-to-failure testing methodologies.

Technical Features

- PLC-controlled unit guarantees industrial-level stability, complemented by an intuitive HMI touch screen interface for seamless operation.

- Automatic test result tracking and storage facilitate efficient data management and analysis.

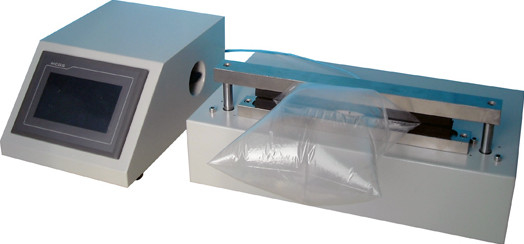

- Versatile compatibility with a range of fixtures accommodates diverse package forms, including three-side-seal, closed packages, doy packs, tubes, sealed trays, and cups.

- Three test modes—burst, creep, and creep to failure—provide flexibility for varied testing requirements.

- Customizable sensitivity and threshold settings ensure precise and tailored evaluations.

- Pressure range extends up to 600KPa, with options for further customization to meet specific testing needs.

- Adheres to ASTM F2054 and ASTM F1140 standards, guaranteeing adherence to industry regulations and quality assurance protocols.

In addition to its primary function of assessing package integrity, the burst tester serves as a crucial instrument for quality assurance and compliance within the packaging industry. By detecting potential leaks and ensuring seal integrity, it mitigates risks associated with product contamination, spoilage, and compromised safety standards. With its advanced capabilities and adherence to industry standards, the burst tester offers peace of mind to manufacturers and consumers alike.

![]()

![]()

Flexible package burst tester features

1. Three test modes of burst, creep and creep to failure are available on Burst Strength Tester.

2. PLC programmable logic controller realizes precise pressure and time control.

3. 7 inch TFT touching screen for convenient parameter setting and test operation.

4. Multiple groups of test parameters can be save to avoid the repetitive setting time.

5. Test result auto statistics and storage.

6. Dual test methods of restraint distension and unrestraint distension

7. Program customization available.

![]()

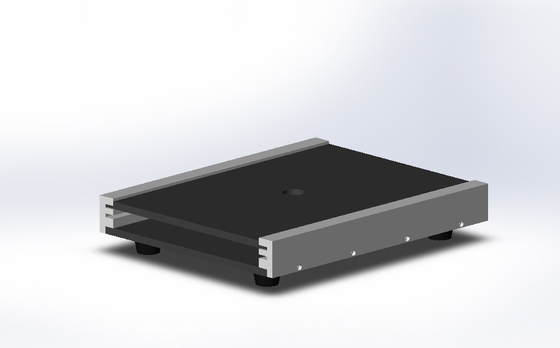

Flexible package burst tester technical specifications

|

Pressure Range |

0~600 KPa |

|

Beam Width |

300mm(for open package) |

|

Inflating Head |

Φ4mm (Standard for sealed package) |

|

Gas Pressure |

0.4 MPa~0.9 MPa |

|

Port Size |

Φ6 mm PU hose |

![]()

Cell Instruments is committed to development of material testing instruments for plastic, paper, bottle, box, containers, etc., PLC program and machinery customization. Please contact +86 531 88977152 (mail: info#celtec.cn Skype: smrelin ) for more information. Let us be a cell of your quality.

![]()

![]()