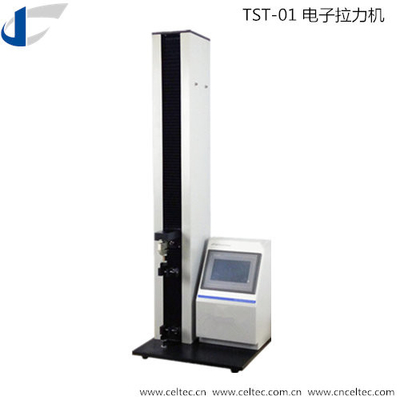

Plastic Tensile Performance Testing Universal Tensile Strength Testing Machine

| Product Name | Nylon Material Tensile Testing Machine,Electronic Tensile Testing Machine | Accuracy | ±0.5% |

|---|---|---|---|

| Test Speed | 1-500mm/min (adjustable ) | Screw | High Precise Ball Screw |

| Highlight | tensile,testing machine,UTM |

||

Plastic Tensile Performance Testing Universal Tensile Strength Testing Machine

![]()

| TST-01 | |

| Test Range | 0-500N (or 50N, 100N, 200N, etc) |

| Stroke | 800mm (customizable for other strokes) |

| Test Speed | 1~500mm/min |

| Displacement Accuracy | 0.01mm |

| Accuracy | 0.5% Full Scale |

| Sample Width | 27mm (optional width available) |

| Control | PLC and HMI Screen |

| Data Output | Microprinter (optional), RS232 (optional) |

The Universal Tensile Strength Testing Machine is an advanced and versatile testing instrument designed to measure the tensile, peeling, tearing, and deformation properties of various materials. It is widely used in industries such as packaging, food, pharmaceuticals, beverages, and academia to assess material strength, durability, and quality. With its precision and ease of use, this machine ensures accurate results for both research and quality control applications.

The Universal Tensile Strength Testing Machine is crucial for testing physical properties like tensile strength, elongation, and tear resistance in materials such as plastic films, composite materials, adhesives, non-woven fabrics, rubber, paper, and much more. Laboratories and manufacturers rely on this machine to guarantee product compliance with industry standards and optimize material performance.

Applications of the Universal Tensile Strength Testing Machine

This versatile machine is suitable for a wide range of material testing applications:

- Plastic Films and Packaging Materials: Test tensile strength, elongation, and tear resistance to ensure the durability and performance of packaging materials.

- Adhesives and Labels: Evaluate peeling and adhesive strength for packaging, labels, medical tapes, and stickers to ensure strong bonding and reliability.

- Non-Woven Fabrics: Test mechanical properties like tensile strength and elongation, widely used in medical textiles, hygiene products, and industrial applications.

- Composite Materials: Assess tensile strength and deformation properties of high-performance materials used in aerospace, automotive, and industrial sectors.

- Paper and Cardboard: Measure tear strength, tensile properties, and elongation for paper products used in packaging and printing industries.

- Rubber and Elastomers: Test tensile and elongation properties of rubber materials used in industrial applications, automotive parts, and consumer goods.

Key Features of the Universal Tensile Strength Testing Machine

- 7-inch TFT Touch Screen: The intuitive touch screen makes it easy to set parameters, initiate tests, and monitor real-time results.

- PLC Programmable Logic Controller: The advanced control system ensures precise control over the driving system and overall machine performance, enhancing the accuracy of tests.

- Precision Ball Screw: Ensures accurate speed and displacement control, essential for consistent and reliable test results.

- Adjustable Test Speed: Offers flexibility in testing various materials with different mechanical properties by adjusting the speed from 1 to 500 mm/min.

- Multiple Testing Capabilities: The Universal Tensile Strength Testing Machine can perform a variety of tests, including tensile, peeling, puncture, and tearing.

- Versatile Fixtures: Equipped with multiple fixtures to accommodate different material types and test scenarios, including both pulling and compression tests.

- Safety Features: Limiting devices and automatic returning functions provide a safe and user-friendly operating experience.

- Optional Microprinter: The machine can be fitted with a microprinter for printing real-time test results, making it convenient for data collection and analysis.

Technical Specifications

- Test Range: 0-500N (Standard); Optional ranges include 50N, 100N, 200N, and 1000N.

- Test Speed: Adjustable between 1 and 500 mm/min, allowing flexibility for different materials and test requirements.

- Accuracy: ±0.5% Full Scale (F.S.), ensuring precise, consistent test results.

- Effective Stroke: 800mm, suitable for testing a variety of material sizes and elongation requirements.

Compliance with International Standards

The Universal Tensile Strength Testing Machine is designed to comply with international testing standards, providing reliable and trustworthy test results that meet industry requirements. These standards include:

- ISO 37: Standard for tensile properties of vulcanized and thermoplastic rubbers.

- ASTM D882: Test method for tensile properties of thin plastic sheeting.

- ASTM E4: Standard practices for force verification of testing machines.

- ASTM D3330: Test method for peel adhesion of pressure-sensitive tapes.

- ASTM F904: Test method for comparison of peel or stripping characteristics of adhesive bonds.

- ASTM F88: Standard test method for seal strength of flexible barrier materials.

- ASTM D1938: Standard test method for tear propagation resistance of plastic film and thin sheeting.

- JIS P8113: Japanese Industrial Standard for tensile testing of paper.

Why Choose the Universal Tensile Strength Testing Machine?

- Precision and Reliability: The Universal Tensile Strength Testing Machine ensures consistent, precise results with high accuracy and repeatability, making it ideal for demanding research and quality control applications.

- Customizable Test Parameters: Its wide range of test speeds and forces allows you to tailor tests for specific material requirements, ensuring the most accurate and relevant results for each application.

- Versatility Across Industries: Whether you're testing packaging materials, adhesives, textiles, or industrial composites, the Universal Tensile Strength Testing Machine provides comprehensive testing solutions for a variety of industries.

- Global Compliance: The machine adheres to widely accepted international standards, providing confidence in your materials' compliance with industry regulations.

- Ease of Use: The user-friendly interface and automated features simplify the testing process, improving productivity in laboratory and production environments.

Benefits of the Universal Tensile Strength Testing Machine

- Increased Product Quality: By providing reliable data on the tensile, peeling, and tear strength of materials, this machine helps manufacturers improve product quality and performance.

- Reduced Material Waste: Testing materials for durability and strength helps identify areas for improvement, reducing waste and optimizing material usage during production.

- Faster Testing Cycles: The automated return function and adjustable test speed help speed up the testing process, allowing for more tests in a shorter period.

- Comprehensive Material Testing: With its ability to test various mechanical properties, including tensile strength, peeling, tearing, and puncture force, this machine is a complete solution for material testing needs.

- Compliance Assurance: By adhering to global standards, the Universal Tensile Strength Testing Machine ensures that your products meet industry-specific regulatory requirements, giving you peace of mind in product safety and performance.

Typical Use Cases

- Packaging Industry: Ensures the tensile and tear strength of plastic films, paper, and cardboard materials used in packaging to maintain product integrity.

- Pharmaceutical Industry: Tests medical packaging materials for durability and strength to ensure product safety and compliance.

- Adhesive and Sealant Manufacturing: Evaluates the strength and adhesion properties of tapes, stickers, and other adhesive products.

- Textile and Non-Woven Fabrics: Tests the tensile and elongation properties of materials used in healthcare, hygiene products, and industrial applications.

- Rubber and Elastomer Products: Tests the strength and elasticity of rubber materials for automotive, industrial, and consumer goods applications.

![]()