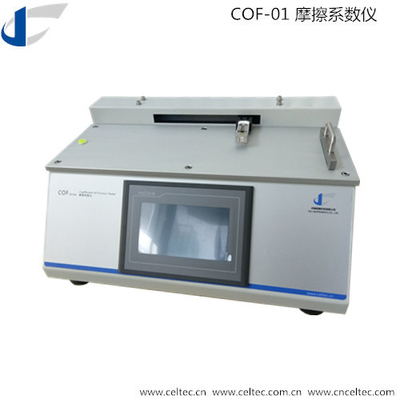

COF Friction Tester ASTM D1894 ISO 8295 Coefficient Of Friction Tester

| Power | Electronic | Usage | Paper Testing Instrument,Textile Testing Instrument,Other,Plastic Testing Machine |

|---|---|---|---|

| Standard | ISO8295,ASTM D1894 | Warranty | 12 Months |

| Product Name | Packaging Materials Coefficient Of Friction Tester | Function | Kinetic And Static Coefficients Of Coefficient Of Friction Test,coefficient Friction Tester,detecting Dynamic Frition Coefficient |

| Power Supply | 110~220V | ||

| Highlight | COF,static and kinetic,friction |

||

COF Friction Tester ASTM D1894 ISO 8295 Coefficient Of Friction Tester

![]()

| COF-01 Coefficient of Friction Tester | |

| Load Cell | 5 N(or as required) |

| Accuracy | 0.5 F.S. |

| Sled | 200±1g (or as required) |

| Sled Size | 63.5mm*63.5mm (or as required) |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) |

| Dimensions | 540mm(L)*380mm(W)*240mm(H) |

| Weight | NW 21kg |

| Power | 110~220V 50/60Hz |

The COF-01 Friction Tester is designed for the precise determination of both static and kinetic coefficients of friction (COF) in a wide range of materials. It plays a critical role in industries like packaging, food, pharmaceuticals, and other sectors where understanding the frictional properties of materials is essential for product performance. This tester ensures materials such as plastic films, paper, fabrics, and rubber meet the highest quality standards by providing accurate friction measurements.

By leveraging advanced technology and adhering to major testing standards like ASTM D1894 and ISO 8295, the COF Friction Tester offers reliability and consistency in results, helping companies improve their product development, quality control, and compliance processes.

Importance of Friction Testing in Industry

In various industries, particularly packaging, understanding friction is critical. The COF Friction Tester helps determine how materials interact with each other during manufacturing, packaging, transportation, and storage. The coefficient of friction directly impacts the ability to process materials on automated machinery, the ease of handling, and the overall quality of the product. Factors such as material composition, surface treatment, and environmental conditions can all influence friction, making testing essential.

Application of the COF Friction Tester

The COF Friction Tester measures both static (µs) and kinetic (µd) coefficients of friction, ensuring detailed analysis of material behavior under different conditions. With this device, companies can optimize material performance, minimize processing issues, and enhance the quality of final products. The tester is suitable for use in industries such as:

- Packaging: Ensuring the smooth handling of films and sheets in automated systems.

- Pharmaceuticals: Testing the friction of materials used in packaging medical products.

- Food and Beverage: Measuring the friction properties of packaging to ensure ease of use and product safety.

- Textiles: Evaluating fabrics for friction performance, improving product feel and durability.

Features of the COF Friction Tester

- PLC Control and HMI Touch Screen: This intuitive system ensures easy operation, allowing users to efficiently set up tests and manage data.

- Precision Ball Lead Screw Mechanism: Guarantees the accuracy and repeatability of test results by providing a stable and precise motion of the test sled.

- Real-Time Test Curve Display: Instant feedback with maximum, minimum, and average test results automatically recorded, ensuring accurate data tracking.

- Comprehensive Testing: Measures both static and kinetic coefficients of friction, offering a complete understanding of material friction behavior.

- Compliance with Standards: The COF Friction Tester meets international standards like ASTM D1894, ISO 8295, TAPPI T816, and GB 10006, making it suitable for global applications.

- Microprinter and Data Output: Includes an integrated microprinter for easy report generation and RS232 output for advanced data management via optional professional software.

- Durable Aluminum Test Plane: Built for long-lasting performance, with high resistance to wear and tear.

- Customizable Display: Local language support enhances usability across different regions.

Technical Specifications of COF Friction Tester

- Load Cell: 5 N (customizable as required)

- Accuracy: 0.5% Full Scale

- Sled: 200±1g (customizable as required)

- Sled Size: 63.5mm x 63.5mm (customizable as required)

- Test Speed: 100mm/min (ISO), 150mm/min (ASTM)

- Dimensions: 540mm(L) x 380mm(W) x 240mm(H)

- Weight: 21kg

- Power Supply: 110~220V 50/60Hz

Benefits of Using the COF Friction Tester

- Improved Product Quality: By measuring the friction properties of materials, companies can ensure their products meet performance requirements during packaging, transport, and usage.

- Increased Efficiency in Manufacturing: Accurate COF measurements help optimize machinery settings and material handling processes, reducing waste and improving production speed.

- Compliance with International Standards: The COF Friction Tester adheres to ASTM, ISO, and TAPPI standards, ensuring your products meet global regulatory requirements.

- Enhanced Data Analysis: With the optional software for data output, companies can perform in-depth analysis and generate detailed reports, aiding in quality control and research and development.

COF Friction Tester Principle

The COF Friction Tester operates on a simple yet effective principle. Two samples are placed in contact, with one fixed on a flat surface while the other is subjected to force via a sled. The friction force is measured when the two materials slip against each other. The system calculates both static and kinetic friction coefficients using the formula:

Where:

- μ is the coefficient of friction

- f is the force of friction

- N is the normal force

Why Choose the COF Friction Tester?

- Versatile Testing Capabilities: Suitable for a wide range of materials, including films, sheets, rubber, and fabrics, this tester is an essential tool for quality control in many industries.

- User-Friendly Interface: The intuitive touch screen interface and advanced control system make it easy to operate and manage tests, even for users with minimal experience.

- Reliable and Consistent Results: By adhering to industry standards and using precision components, the COF Friction Tester delivers accurate and repeatable test results, ensuring product reliability.

- Comprehensive Data Management: With integrated microprinting and data export capabilities, users can easily manage and analyze test results, making it ideal for both routine testing and research applications.

![]()