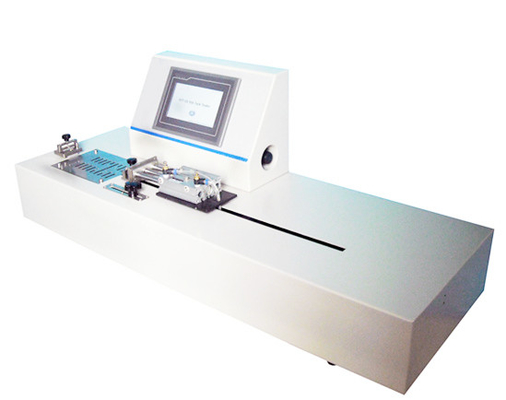

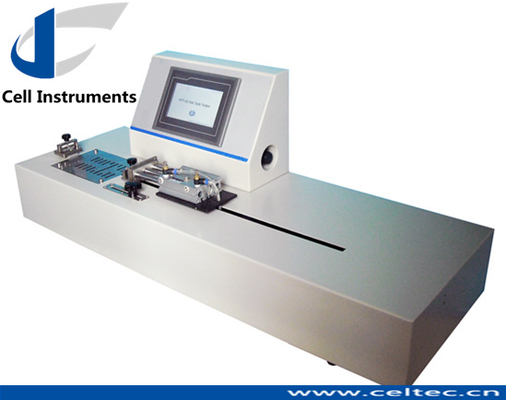

Hot Tack Seal Tester Astm F1921 Conformed Both Method A And Method B

| Power | AC 220V 50Hz | Usage | Plastic Testing Machine |

|---|---|---|---|

| Product Name | Hot Tack Tester,Property Test For Plastic Film Hot Tack Tester,Flexible Package Hot Tack Testing Machine HTT- 01,Heat Seal And Hot Tack Tester HTT- 01 Hot Tack Force Tester | Standard | ASTM F1921 |

| Highlight | Hot Tack,sealer,seal strength |

||

Hot Tack Seal Tester Astm F1921 Conformed Both Method A And Method B

![]()

| Sealing Temp. | Ambient~250℃ |

| Temp Accuracy | ±0.2℃ |

| Dwell Time | 0.1~9999s(Heat Seal ) |

| Dwell Time | 0.1~9999s(Hot Tack ) |

| Sealing Pressure | 0.15MPa~0.7MPa |

| Sealing Jaws | 50mmx10mm Teflon Coated |

| Jaws Heating | Double Heating |

| Load Cell | 200N(Optional:30N50N100N, etc) |

| Accuracy | 0.5 F.S. |

| Resolution | 0.01N |

| Power | 220V, 50 HZ |

Hot Tack Seal Tester: Precision in Sealing Technology

The Hot Tack Seal Tester is an essential instrument for industries requiring precise measurement of sealing properties. Conforming to ASTM F1921, this advanced testing equipment is designed to evaluate the hot tack strength of heat seals, ensuring quality and performance across various applications, including packaging, food, and pharmaceuticals.

Compliance with Standards

Our Hot Tack Seal Tester meets rigorous industry standards, including ASTM F2029, QB/T 2358, and YBB 00122003, guaranteeing reliability and accuracy in your testing processes.

Key Features of the Hot Tack Seal Tester

- User-Friendly Interface: The 7-inch TFT touchscreen simplifies parameter settings and operational controls, making it accessible for users at all experience levels.

- Precise Control Mechanisms: Equipped with a PLC (Programmable Logic Controller) for exact dwell time and sealing pressure control, the Hot Tack Seal Tester delivers consistent results.

- Advanced Temperature Regulation: The P.I.D. (Proportional, Integral, Derivative) system ensures accurate sealing temperature control, crucial for reliable test outcomes.

- Uniform Heating Technology: Our aluminum encapsulated sealing jaws guarantee uniform heating, eliminating inhomogeneous temperature distribution that can affect seal integrity.

- Customizable Sealing Jaws: The Hot Tack Seal Tester offers customization options for sealing jaws in terms of dimension, shape, and surface, catering to specific testing needs.

- Independent Heating: The ability to independently heat the upper and lower sealing jaws allows for versatile testing scenarios and enhances the accuracy of seal strength measurements.

Technical Specifications

- Temperature Range: Room Temperature to 300℃

- Temperature Deviation: ±0.2℃

- Dwell Time: 0.1 seconds to 9999 seconds

- Sealing Pressure: 0.15 MPa to 0.7 MPa

- Sealing Jaw Dimensions: 330mm × 10mm (Customizable)

- Heating Mechanism: Double heating of upper and lower jaws

Applications of the Hot Tack Seal Tester

The Hot Tack Seal Tester is vital for testing materials in various sectors:

- Packaging Industry: Evaluate the performance of heat seals in flexible packaging solutions.

- Food Industry: Ensure the integrity of seals on food packaging to maintain freshness and safety.

- Pharmaceuticals: Validate the reliability of seals on medication packaging, crucial for product stability and compliance.

- Beverages: Test the sealing capabilities of containers, ensuring product quality and longevity.

Benefits of Using the Hot Tack Seal Tester

- Enhanced Quality Control: Regular testing with the Hot Tack Seal Tester helps maintain high standards of product quality.

- Increased Efficiency: Streamlined operations with user-friendly controls lead to faster testing cycles.

- Cost-Effective Solutions: By ensuring proper sealing techniques, the Hot Tack Seal Tester helps reduce waste and product recalls.

Summary

Investing in the Hot Tack Seal Tester means prioritizing quality and reliability in your sealing processes. Its precise controls and advanced technology make it an invaluable tool for any laboratory or manufacturing setting concerned with material integrity.

![]()