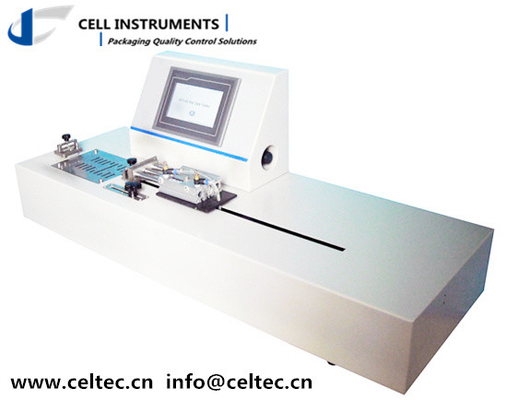

Peeling And Tensile Tester Hot Tack Polymer Test ASTM F1921

| Product Name | Hot Tack Tester,Property Test For Plastic Film Hot Tack Tester | Seal Temperature | Room Temperature~250 |

|---|---|---|---|

| Keyword | Hot Tack Tester,hot Tack Testing Equipment | Warranty | 12 Months |

| Power Supply | AC 220V | Standard | ASTM F1921 |

| Resolution | 0.01N | ||

| Highlight | peeling,tensile,tester |

||

Peeling And Tensile Tester Hot Tack Polymer Test ASTM F1921

The Hot Tack Polymer Test is an essential laboratory instrument for testing the physical properties of materials, primarily used to evaluate the strength of heat seals between thermoplastic surfaces immediately after sealing, before they cool to room temperature. This test is especially crucial for vertical form-fill-seal (VFFS) packaging applications, where precise and reliable sealing is critical for product quality and safety.

By integrating Hot Tack Polymer Test, heat sealing, peeling, and tensile testing in one device, this tester provides comprehensive analysis for packaging materials. It is highly valued in industries such as food, pharmaceuticals, and packaging, ensuring that sealed packages maintain their integrity during shipping, storage, and use.

![]()

Key Features of the Hot Tack Polymer Test

-

Comprehensive Testing Capabilities: The Hot Tack Polymer Test combines hot tack, heat seal, peeling, and tensile tests in one advanced instrument, making it an indispensable tool for laboratories focused on material quality.

-

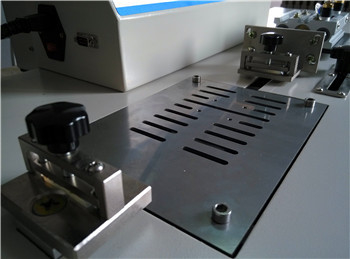

Precision Control with P.I.D. Temperature: The sealing jaws are managed by a P.I.D. temperature controller, ensuring that temperature rises quickly to the set level and remains stable throughout the test.

-

User-Friendly Operation: The tester is equipped with a 7-inch TFT touchscreen for intuitive and efficient operation, allowing for easy adjustments and monitoring of test parameters.

-

High Durability and Performance: The sealing jaws are encapsulated in aluminum, providing even heating distribution and extending the lifespan of the machine.

-

Adjustable Testing Speeds: With adjustable test speeds, users can tailor the Hot Tack Polymer Test to meet specific material requirements, ensuring versatile application across a wide range of products.

-

Enhanced Safety Features: The instrument includes anti-scald design elements, along with manual and foot switch start options for added safety during operation.

-

Auto Zeroing and Protection: Automatic zeroing, overload, and over-travel protection are integrated into the system to prevent operational issues and ensure consistent, accurate results.

-

Data Connectivity and Software Integration: Equipped with an RS 232 port and optional professional software, the tester offers seamless data transfer and comprehensive analysis, making it easier to interpret results and maintain records.

Applications of Hot Tack Polymer Test

The Hot Tack Polymer Test plays a pivotal role in quality control for various industries, including:

- Packaging: Ensures the integrity of sealed packages in food, beverages, and consumer goods.

- Pharmaceuticals: Guarantees that medicinal products remain secure and uncontaminated during transportation.

- Cosmetics: Confirms the durability of product packaging for creams, lotions, and other beauty products.

- Food and Beverage: Assesses the strength of heat seals in packaging, ensuring that products are protected from contamination or spoilage.

Technical Specifications

| Feature | Specification |

|---|---|

| Sealing Temperature | Ambient ~ 250℃ |

| Temperature Accuracy | ±0.2℃ |

| Heat Seal Dwell Time | 0.1~9999s |

| Hot Tack Dwell Time | 0.1~9999s |

| Sealing Pressure | 0.15MPa ~ 0.7MPa |

| Sealing Jaws Dimensions | 50mm x 10mm, Teflon Coated |

| Sealing Jaws Heating | Double Heating |

| Load Cell | 200N (Optional: 30N, 50N, 100N, 500N) |

| Accuracy | 0.5 F.S. |

| Resolution | 0.01N |

| Stroke | 500mm |

| Gas Source | 0.5MPa ~ 0.7MPa |

| Port Size | Ф6mm PU Hose |

| Dimensions | 1100mm(L) × 390mm(W) × 420(H) |

This comprehensive set of technical features ensures that the Hot Tack Polymer Test provides accurate and reliable data for quality assurance purposes across multiple industries.

Standards and Compliance

The Hot Tack Polymer Test adheres to international testing standards, ensuring that users receive results that meet industry requirements. These standards include:

- ASTM F1921: Standard Test Method for Hot Tack of Thermoplastic Materials.

- ASTM F2029: Standard Practices for Hot Tack Testing of Heat Seal Coatings for Flexible Packaging.

- QB/T2358: Chinese standard for testing materials.

- YBB 00122003: A pharmaceutical packaging material standard used in China.

These compliance standards reinforce the accuracy, reliability, and relevance of the Hot Tack Polymer Test, making it suitable for businesses that require high levels of quality assurance and material testing accuracy.

Industries Benefiting from the Hot Tack Polymer Test

![]()

-

Food Packaging: Food manufacturers use the Hot Tack Polymer Test to evaluate the quality of sealed pouches, containers, and bags, ensuring that products remain fresh and uncontaminated.

-

Pharmaceuticals: Medicine packaging demands strong seals that protect the integrity of the product. This tester ensures that pharmaceutical packaging complies with stringent safety standards.

-

Beverage Packaging: In the beverage industry, strong seals are essential to avoid leaks and maintain freshness. The Hot Tack Polymer Test is an important tool in ensuring packaging quality.

-

Research and Academia: Research institutions and universities use this tester to explore new materials and packaging methods, contributing to advancements in material science and packaging technology.