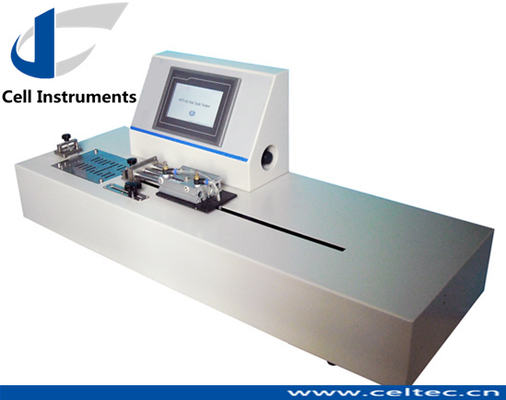

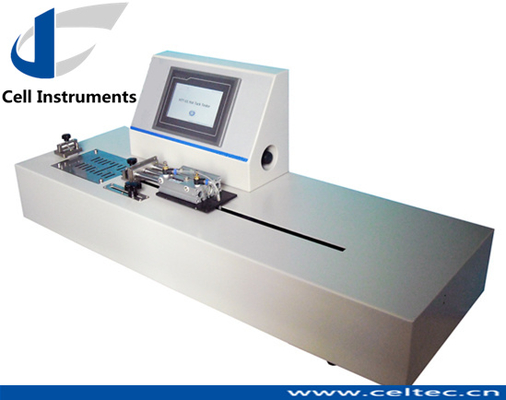

Flexible Package Hot Tack Testing Machine ASTM F1921 Hot Tack Tester

| Product Name | Hot Tack Tester,Property Test For Plastic Film Hot Tack Tester,Flexible Package Hot Tack Testing Machine HTT- 01,Heat Seal And Hot Tack Tester HTT- 01 Hot Tack Force Tester | Standard | ASTM F1921 |

|---|---|---|---|

| Sealing Temp. | Ambient~250℃ | Temp Accuracy | ±0.2℃ |

| Sealing Pressure | 0.15MPa~0.7MPa | Sealing Jaws | 50mmx10mm Teflon Coated |

| Jaws Heating | Double Heating | ||

| Highlight | Flexible Package,testing machine,package material |

||

Flexible Package Hot Tack Testing Machine ASTM F1921 Hot Tack Tester

![]()

| Sealing Temp. | Ambient~250℃ |

| Temp Accuracy | ±0.2℃ |

| Dwell Time | 0.1~9999s(Heat Seal ) |

| Dwell Time | 0.1~9999s(Hot Tack ) |

| Sealing Pressure | 0.15MPa~0.7MPa |

| Sealing Jaws | 50mmx10mm Teflon Coated |

| Jaws Heating | Double Heating |

| Load Cell | 200N(Optional:30N50N100N, etc) |

| Accuracy | 0.5 F.S. |

| Resolution | 0.01N |

| Power | 220V, 50 HZ |

Introducing the Flexible Package Hot Tack Testing Machine – a state-of-the-art instrument designed to evaluate the hot tack properties of heat-sealed layers with precision and efficiency. Our HTT-02 Flexible Package Hot Tack Testing Machine complies with ASTM F1921 standards, ensuring top-tier performance in critical industries such as packaging, food, pharmaceuticals, beverages, and more. This device offers unmatched accuracy, making it indispensable for testing seals under demanding conditions.

Application of the Flexible Package Hot Tack Testing Machine

The Flexible Package Hot Tack Testing Machine is specifically engineered to assess the strength of heat seals formed between thermoplastic surfaces. This assessment is crucial in industries like packaging, where heat-sealed bags and pouches are filled and sealed almost simultaneously in vertical form-fill-seal (VFFS) processes. The ability to test seals while they are still hot and under pressure ensures that packaging lines operate efficiently and that product integrity remains intact.

This machine is ideal for testing in industries including:

- Food packaging: Ensures airtight seals that preserve freshness and prevent leakage.

- Pharmaceutical packaging: Confirms the robustness of seals for safety and product integrity.

- Beverage packaging: Evaluates the strength of seals in liquid containers to prevent spills and contamination.

- Medical devices: Verifies the durability of sealed packaging for sterile instruments.

With its ability to test seals under high loads and varying temperatures, the Flexible Package Hot Tack Testing Machine offers unparalleled flexibility and precision.

Importance of Hot Tack Testing in Packaging

In packaging processes like VFFS, very little time is available between sealing and filling. During this brief cooling period, the heat-sealed layer must withstand the stress of filling, which makes hot tack testing critical for ensuring the seals do not fail. The Flexible Package Hot Tack Testing Machine replicates these real-world conditions, allowing manufacturers to guarantee that their seals are strong enough to maintain product integrity even under heavy loads.

Without effective hot tack testing, products can suffer from packaging failures such as leaks, contamination, or compromised freshness, all of which negatively affect product quality and customer satisfaction. By using the HTT-02 Flexible Package Hot Tack Testing Machine, companies can enhance the durability of their packaging, reduce the risk of product recalls, and ensure regulatory compliance.

Compliance with ASTM F1921 Standards

Our Flexible Package Hot Tack Testing Machine is fully compliant with ASTM F1921, a key standard for testing the hot tack properties of heat-sealed layers in thermoplastic packaging. This compliance ensures that the machine provides accurate and reliable results, as specified by the standard's Method A and Method B testing procedures. ASTM F1921 is essential for industries where heat sealing plays a crucial role in product packaging and quality control.

By adhering to ASTM F1921, the HTT-02 Flexible Package Hot Tack Testing Machine provides peace of mind for businesses that require consistent, high-quality testing to maintain their competitive edge.

Operating Principle

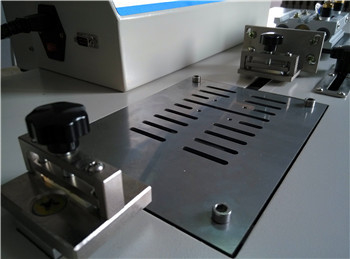

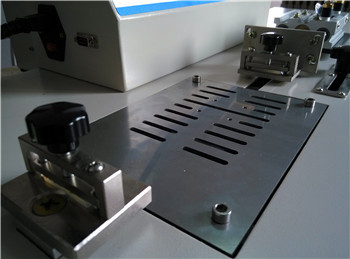

The Flexible Package Hot Tack Testing Machine operates based on a principle of controlled conditions. It uses flat, heated jaws to seal sample strips of thermoplastic under specific parameters, such as temperature, contact time, and pressure. These controlled conditions allow for an accurate evaluation of hot tack strength, which is essential for gauging how well a seal will perform under actual packaging conditions.

Whether it’s evaluating seals for plastic bags, pouches, or other flexible packaging materials, the HTT-02 ensures that manufacturers can confidently determine the hot tack strength of their products, ensuring that they meet both performance and safety standards.

Technical Features

- Advanced PLC control: Ensures industrial-level stability for consistent and accurate test results.

- User-friendly 7-inch HMI touch screen: Simplifies operation and data management with an intuitive interface.

- Precision P.I.D. temperature control: Guarantees accurate and reliable testing conditions, allowing users to set precise parameters.

- Durable aluminum encapsulated sealing jaws: Built for longevity and consistent performance, ensuring reliable sealing over extended use.

- Auto-zeroing and overload protection: Adds layers of safety and accuracy, preventing damage to the equipment and ensuring high-precision testing.

- Adjustable test speeds: Tailors the testing process to meet specific application needs.

- Optional RS 232 port and professional software: Enables advanced data management and integration with existing laboratory information systems, enhancing workflow efficiency.

These technical features combine to make the Flexible Package Hot Tack Testing Machine an essential tool for companies that rely on precision and reliability in their packaging processes.

Main Parameters

| Parameter | Specification |

|---|---|

| Sealing Temperature | Ambient ~ 250℃ |

| Temperature Accuracy | ± 0.2℃ |

| Dwell Time (Heat Seal) | 0.1 ~ 9999s |

| Dwell Time (Hot Tack) | 0.1 ~ 9999s |

| Sealing Pressure | 0.15MPa ~ 0.7MPa |

| Sealing Jaws | 50mm x 10mm Teflon Coated |

| Jaws Heating | Double Heating |

| Load Cell | 200N (Optional: 30N, 50N, 100N, etc.) |

| Accuracy | 0.5 F.S. |

| Resolution | 0.01N |

| Power | 220V, 50HZ |

These technical specifications make the Flexible Package Hot Tack Testing Machine one of the most reliable and accurate testing instruments available on the market.

Why Choose the Flexible Package Hot Tack Testing Machine?

- Industry-leading precision: The HTT-02 Flexible Package Hot Tack Testing Machine offers highly accurate testing results that are essential for ensuring the quality and durability of packaging.

- Compliance with global standards: Fully compliant with ASTM F1921, this machine meets the rigorous requirements of industries that prioritize product safety and packaging integrity.

- User-friendly design: With its intuitive touch screen and advanced features, this machine simplifies the testing process, making it accessible for operators of all skill levels.

- Versatility: Suitable for various industries, including food, pharmaceuticals, beverages, and medical devices, this machine is a versatile tool for testing the strength of flexible packaging.

By investing in the Flexible Package Hot Tack Testing Machine, companies can improve their packaging processes, reduce the risk of product failures, and ensure that their packaging meets both industry and regulatory standards.

![]()