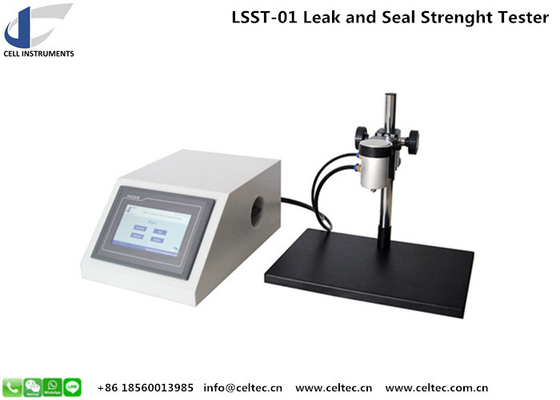

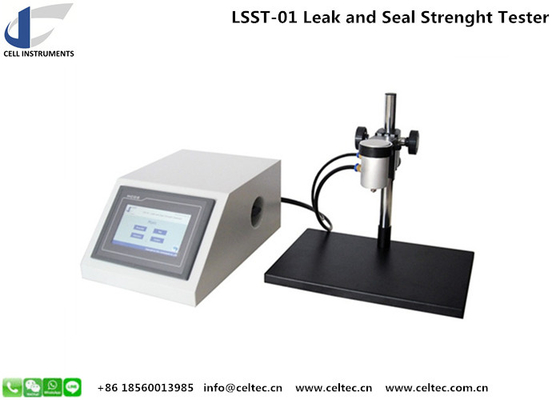

Leak And Seal Strength Detector Pressure Decay Burst Tester Creep To Failure Leakage Tester

| Power | 110~220V | Standards | ASTM F1140 ASTM F2054 |

|---|---|---|---|

| Highlight | seal strength,burst tester,burst stength |

||

Leak And Seal Strength Detector Pressure Decay Burst Tester Creep To Failure Leakage Tester

| LSST-01 Leak and Seal Strength Tester | |

| Test Range | 0~600KPa |

| Sample Width | 300mm (standard) |

| Inflating Head | Φ4mm |

| Compressed Air | 0.4~0.7MPa (Prepared by user) |

| Power | 110~220V 50/60Hz |

The Leak And Seal Strength Detector is an essential tool designed for accurately testing the sealing strength, burst pressure, and leakage of flexible packages, containers, bottles, tubes, cups, and more. This precision instrument is widely used in various industries such as packaging, pharmaceuticals, food, beverages, and laboratories. It offers comprehensive testing capabilities that ensure product integrity and compliance with international standards, making it a must-have for manufacturers and quality control departments.

This instrument is particularly suitable for testing the sealing and integrity of flexible packaging materials used in food packaging, medical device packaging, and more. Whether it's evaluating the burst strength of a food package or detecting leaks in a medical-grade pouch, the Leak And Seal Strength Detector provides precise results that help manufacturers meet rigorous safety and quality standards.

Key Features of the Leak And Seal Strength Detector

-

Three Test Modes for Comprehensive Analysis

The Leak And Seal Strength Detector offers three distinct testing modes: Burst Test, Creep Test, and Creep to Failure. These modes enable precise testing for various material types and applications, allowing users to assess packaging performance under different stress conditions.- Burst Test: This test assesses the maximum pressure a package can withstand before it bursts, offering critical insights into packaging durability.

- Creep Test: Evaluates how a package holds up under a constant load over a specified period, ensuring the package can maintain integrity over time.

- Creep to Failure Test: A comprehensive test to determine when the package will fail under a consistent load, helping predict potential issues in real-world scenarios.

-

High-Precision Technology

The Leak And Seal Strength Detector is powered by a PLC programmable logic controller, ensuring highly accurate and repeatable test results. Its 7-inch human-machine interface (HMI) provides an intuitive user experience, enabling users to operate the system with ease. -

Automatic Test Result Statistics

Once tests are completed, the instrument automatically generates detailed statistics, simplifying data collection and analysis. This helps laboratories and quality control departments streamline the testing process, ensuring faster decision-making based on real-time data. -

Customization for Specific Testing Requirements

Both the testing programs and sample holding accessories can be customized according to the specific requirements of the user. Whether you need a tailored program for a unique packaging type or specialized sample holders for irregularly shaped products, the Leak And Seal Strength Detector offers flexibility to suit a variety of testing needs. -

Compliance with Global Standards

The Leak And Seal Strength Detector complies with international testing standards, including ISO 11607-1, ISO 11607-2, ASTM F1140, and ASTM F2054. This makes it a reliable choice for companies looking to meet global regulatory requirements and maintain the highest quality standards.

Applications of Leak And Seal Strength Detector

The Leak And Seal Strength Detector is highly versatile and is used across several industries. Here are some of the common applications:

- Food Packaging Testing: Ensures that flexible packaging can withstand transportation and handling without leaks or bursts, thus preserving food quality and safety.

- Medical Device Packaging: Assesses the integrity of sterilized medical device packaging to prevent contamination, ensuring compliance with ISO and ASTM standards.

- Pharmaceuticals: Used to evaluate the sealing strength of packaging for pills, powders, and liquids to maintain product efficacy and safety.

- Beverage Industry: Tests the seal strength of bottles and containers to ensure product freshness and prevent leakage during distribution.

- Research Laboratories: Provides a reliable way to test new packaging materials and technologies, supporting innovation and product development.

Technical Specifications of Leak And Seal Strength Detector

-

Pressure Range: 0~600 KPa

The wide pressure range allows the instrument to test a variety of packaging materials, from lightweight films to heavier-duty packaging. -

Beam Width: 300 mm (for open packages)

A large beam width is ideal for testing wide package types like pouches and larger containers, providing consistent and accurate results. -

Inflating Head: Φ4 mm (Standard for sealed packages)

The specialized inflating head design ensures that even sealed packages can be thoroughly tested for leaks without damaging the material. -

Gas Pressure: 0.4 MPa ~ 0.9 MPa

The adjustable gas pressure allows flexibility in testing different packaging types, providing accurate measurements without overloading the material. -

Port Size: Φ6 mm PU hose

Standard hose sizes make it easy to connect the detector to existing systems in the laboratory, ensuring smooth and efficient operation.

Benefits of Using the Leak And Seal Strength Detector

-

Increased Product Reliability

By utilizing the Leak And Seal Strength Detector, manufacturers can ensure that their packaging meets stringent safety and quality requirements, preventing costly product recalls and enhancing brand reputation. -

Compliance with Industry Standards

With built-in compliance to ISO and ASTM standards, companies can confidently use the Leak And Seal Strength Detector to verify that their packaging is up to code, ensuring smooth regulatory approval and market access. -

Improved Efficiency

The automatic test result statistics and intuitive interface allow for faster and more efficient testing, reducing downtime and improving overall productivity in the lab or production facility. -

Customizable for Diverse Testing Needs

The customizable test programs and accessories make the Leak And Seal Strength Detector suitable for a wide range of industries and packaging types, providing unparalleled versatility.

![]()

![]()