Static COF Tester Kinetic COF tester

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Highlight | COF,friction,material surface |

||

|---|---|---|---|

![]()

![]()

| Load Cell | 5 N(or as required) |

| Accuracy | 0.5 F.S. |

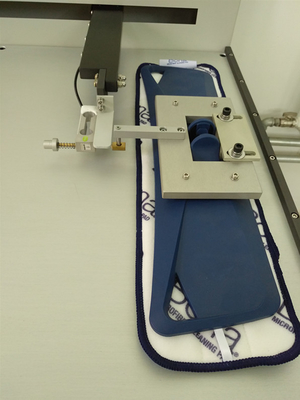

| Sled | 200±1g (or as required) |

| Sled Size | 63.5mm*63.5mm (or as required) |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) |

| Dimensions | 540mm(L)*380mm(W)*240mm(H) |

| Weight | NW 21kg |

| Power | 110~220V 50/60Hz |

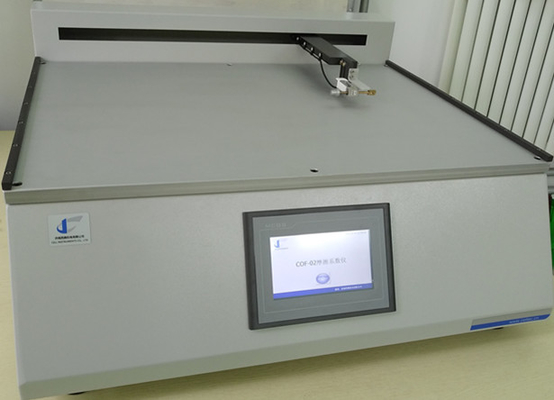

The Static COF Tester Kinetic COF Tester (Model COF-01) is a cutting-edge instrument designed for the accurate determination of static and kinetic coefficients of friction in various materials. This tester is essential for industries such as packaging, food, pharmaceuticals, beverages, and textiles, providing critical data that influences product quality and performance.

Understanding the Principle of the Static COF Tester Kinetic COF Tester

The Static COF Tester Kinetic COF Tester operates on a straightforward yet effective principle. It involves placing two samples together, where a long strip sample is fixed on a flat surface. A sled is then applied to the squared sample, exerting a force. The friction force is meticulously measured as the samples slip against each other, allowing users to ascertain both the static and kinetic coefficients of friction accurately.

Key Features of the Static COF Tester Kinetic COF Tester

- User-Friendly Interface: Equipped with PLC control and a touch screen operation, the Static COF Tester Kinetic COF Tester provides a seamless user experience.

- Real-Time Data Display: Users can view test data, results, and curves in real time, enhancing the analytical process.

- Dual Measurement Capability: This tester can measure both static and kinetic coefficients of friction, making it versatile for various testing scenarios.

- Compliance with Standards: The Static COF Tester Kinetic COF Tester adheres to multiple international standards, ensuring reliability and credibility in testing.

- Advanced Data Analysis: Features such as test results calculation, analysis, and curve superposition empower users to interpret data effectively.

- Connectivity Options: With RS232 output and optional professional software, users can integrate this tester into existing laboratory systems seamlessly.

- Efficient Documentation: The microprint feature allows for easy printing of test results, facilitating record-keeping and reporting.

Technical Specifications

| Specification | Details |

|---|---|

| Load Cell | 5N |

| Accuracy | 0.5 F.S. |

| Stroke | Max 150mm |

| Sled Weight | 200 g (Customization available) |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) |

| Power | AC 220V 50Hz (Customizable) |

| Dimensions | 540mm(L) x 380mm(W) x 240mm(H) |

Compliance Standards

The Static COF Tester Kinetic COF Tester is designed to meet various industry standards, including:

- ASTM D1894: Standard Test Method for Static and Kinetic Coefficient of Friction of Plastic Film and Sheeting.

- ISO 8295: Plastics — Film and sheeting — Determination of the static and kinetic coefficients of friction.

- TAPPI T816: Test Methods for Coefficient of Friction of Paper and Paperboard.

- GB 10006: National Standards of the People’s Republic of China for Plastic Film.

Application of the Static COF Tester Kinetic COF Tester

The Static COF Tester Kinetic COF Tester is versatile, catering to a wide range of applications across industries:

- Packaging Industry: Vital for assessing the slip properties of packaging materials, enhancing packaging design and usability.

- Food and Beverage: Ensures that materials used in food packaging meet safety and quality standards.

- Pharmaceuticals: Guarantees the integrity of packaging materials that come into contact with medical products.

- Textiles: Measures friction in fabrics, aiding in the production of high-quality textile products.

Why Choose the Static COF Tester Kinetic COF Tester?

Investing in the Static COF Tester Kinetic COF Tester ensures your laboratory maintains high standards in testing materials' physical properties. The combination of advanced technology, ease of use, and compliance with international testing standards makes this instrument an invaluable asset for quality control.