Plastic Film Testing Equipment Hot Tack Tester Polymer Hot Seal And Tack Tester Astm F1921 Standard Complied

| Product Name | Hot Tack Tester,Property Test For Plastic Film Hot Tack Tester | Dwell Time | 0.1s~9999s |

|---|---|---|---|

| Keyword | Hot Tack Tester,hot Tack Testing Equipment | Warranty | 12 Months |

| Power Supply | AC 220V | Delay Time | 0.1s~9999s |

| Standard | ASTM F1921 | Resolution | 0.01N |

| Seal Surface | 180 Mm*10 Mm(Customization Is Available) | ||

| Highlight | film,test,equipment |

||

Plastic Film Testing Equipment Hot Tack Tester Polymer Hot Seal And Tack Tester Astm F1921 Standard Complied

| Sealing Temp. | Ambient~250℃ |

| Temp Accuracy | ±0.2℃ |

| Dwell Time | 0.1~9999s(Heat Seal ) |

| Dwell Time | 0.1~9999s(Hot Tack ) |

| Sealing Pressure | 0.15MPa~0.7MPa |

| Sealing Jaws | 50mmx10mm Teflon Coated |

| Jaws Heating | Double Heating |

| Load Cell | 200N(Optional:30N50N100N, etc) |

| Accuracy | 0.5 F.S. |

| Resolution | 0.01N |

| Power | 220V, 50 HZ |

Introducing the advanced Hot Tack Tester, a high-performance instrument designed to accurately measure the hot tack strength of heat-sealed materials, particularly crucial in packaging applications. With versatile applications across industries like packaging, food processing, pharmaceuticals, beverages, and more, this Hot Tack Tester offers precise testing solutions to ensure the quality and durability of thermoplastic seals in real-world environments.

Key Features of the Hot Tack Tester

The Hot Tack Tester is engineered to deliver comprehensive testing capabilities, offering essential insights into the performance of heat seals formed immediately after sealing. This device excels in vertical form-fill-seal (VFFS) processes, where the sealed packages must endure considerable stress while still hot. With integrated testing options for hot tack, heat seal, peel strength, and tensile strength, the Hot Tack Tester ensures optimal testing accuracy and efficiency.

- All-in-One Testing: The instrument integrates hot tack, heat seal, peeling, and tensile tests into one comprehensive system, enabling multi-functional testing for a wide range of materials.

- Precision Temperature Control: The sealing jaws are equipped with P.I.D. temperature control for rapid and stable heating, ensuring consistent testing conditions. Temperature precision is critical in evaluating the seal strength at different temperature ranges.

- User-Friendly Interface: The 7-inch TFT touchscreen enables intuitive operation, while the PLC-controlled system ensures industrial-level stability.

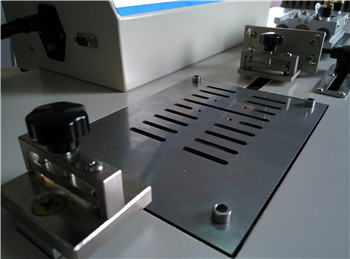

- Durable Sealing Jaws: Constructed from aluminum and designed for even heat distribution, the encapsulated sealing jaws provide reliable performance and long-lasting durability.

- Customizable Parameters: This Hot Tack Tester allows the user to save multiple test parameter settings, streamlining repetitive testing and improving workflow efficiency.

- Advanced Safety Features: The instrument is equipped with auto-zeroing, overload protection, and over-travel protection, ensuring both the accuracy of results and the safety of the testing process.

- Data Management Capabilities: With an optional RS232 port and professional software, the device can connect to external systems for advanced data analysis and record-keeping, improving efficiency and traceability in testing labs.

Applications of Hot Tack Tester

The Hot Tack Tester plays a critical role in industries that rely on the quality of heat seals in packaging materials. This includes packaging for food, beverages, pharmaceuticals, medical devices, and other products that require secure and durable packaging solutions. The tester is particularly valuable in vertical form-fill-seal (VFFS) operations, where minimal cooling time is available between sealing and filling processes. In such applications, evaluating the hot tack strength ensures that seals can withstand product weight and stress immediately after sealing.

Industries Benefiting from the Hot Tack Tester:

- Food and Beverage Packaging: Ensures that the packaging retains integrity during the filling process, preventing leaks or failures in heat-sealed products.

- Pharmaceutical and Medical Packaging: Critical for ensuring that sealed medical and pharmaceutical products meet stringent safety and quality standards.

- Consumer Goods: Applicable for packaging solutions in daily consumer products that require strong and reliable seals to preserve quality.

How Does the Hot Tack Tester Work?

The Hot Tack Tester works by measuring the heat seal strength of thermoplastic materials immediately after sealing. Using heated jaws, the device applies controlled temperature, contact pressure, and test speed to seal the material. The hot tack strength is then measured under specified load conditions to ensure the seal can withstand typical stresses encountered in industrial packaging lines.

Technical Specifications:

- Temperature Range: Ambient to 250°C

- Temperature Accuracy: ±0.2°C

- Dwell Time: 0.1–9999s for both heat seal and hot tack measurements

- Sealing Pressure: 0.15–0.7MPa

- Jaw Dimensions: 50mm x 10mm, Teflon-coated for durability

- Heating: Double-sided heating for uniform temperature distribution

- Load Capacity: 200N (Optional 30N, 50N, 100N)

- Accuracy: 0.5% full scale

- Resolution: 0.01N

- Power Supply: 220V, 50Hz

This comprehensive instrument provides manufacturers and testing labs with the ability to ensure that heat-sealed packages meet stringent quality standards, safeguarding product integrity.

Standards Compliance

The Hot Tack Tester complies with multiple industry standards to ensure that testing is performed accurately and consistently across all applications:

- ASTM F1921: Standard Test Method for Hot Tack of Thermoplastic Materials.

- ASTM F2029: Standard Practices for Making Heat Seals for Determination of Hot Tack.

- QB/T 2358: Chinese national standard for heat seal and hot tack properties.

- YBB 00122003: Chinese pharmaceutical packaging material standard.

Why Choose Our Hot Tack Tester?

Choosing the right Hot Tack Tester for your laboratory or production line is crucial for maintaining product quality and operational efficiency. Our Hot Tack Tester offers unmatched precision and versatility, designed to handle the rigorous demands of modern industrial packaging. Its compliance with leading international testing standards ensures that your packaging meets regulatory requirements, helping you avoid costly product failures and ensuring customer satisfaction.

- Reliable Performance: Precision engineering ensures that the Hot Tack Tester delivers consistent and reliable results across a range of testing conditions.

- User-Friendly Operation: The combination of a 7-inch touchscreen and PLC control simplifies operation, while data storage and retrieval functions help streamline testing procedures.

- Enhanced Durability: Built with high-quality materials, including aluminum encapsulated jaws, the instrument is designed for long-term use in industrial environments.

- Customizable Options: Choose from multiple load cell configurations to suit your specific testing requirements.

![]()

![]()