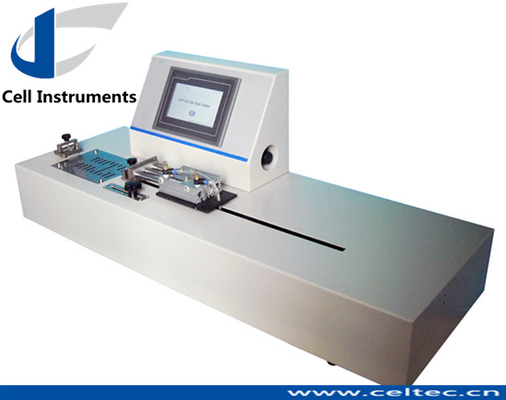

Hot Tack and Seal Strength Tester

| Highlight | ASTM F2029,ASTM F1921,testing |

||

|---|---|---|---|

Hot Tack and Seal Strength Tester

![]()

| HTT-02 Hot Tack Tester | |

| Sealing Temp. | Ambient~250℃ |

| Temp Accuracy | ±0.2℃ |

| Dwell Time | 0.1~9999s(Heat Seal ) |

| Dwell Time | 0.1~9999s(Hot Tack ) |

| Sealing Pressure | 0.15MPa~0.7MPa |

| Sealing Jaws | 50mmx10mm Teflon Coated |

| Jaws Heating | Double Heating |

| Load Cell | 200N(Optional:30N50N100N, etc) |

| Accuracy | 0.5 F.S. |

| Resolution | 0.01N |

| Power | 220V, 50 HZ |

The Hot Tack and Seal Strength Tester is a sophisticated instrument designed to measure the strength of heat seals, providing critical data for ensuring the quality and reliability of packaging. This versatile device evaluates the performance of heat seals in real-time, assessing parameters such as hot tack, seal strength, peeling resistance, and tensile strength. Essential for various industries, including packaging, food, medicine, and beverages, this tester plays a crucial role in maintaining high standards of packaging integrity.

Key Features of the Hot Tack and Seal Strength Tester

-

Integrated Testing Functions: The Hot Tack and Seal Strength Tester combines multiple testing capabilities into one instrument. It efficiently performs hot tack, heat seal, peeling, and tensile tests, making it a comprehensive tool for evaluating package seals.

-

Advanced Temperature Control: Equipped with P.I.D. temperature control, the sealing jaws of the Hot Tack and Seal Strength Tester achieve rapid heating to the set temperature and maintain stability throughout the test, ensuring accurate and reliable results.

-

User-Friendly Interface: The 7-inch TFT touch screen simplifies the operation of the Hot Tack and Seal Strength Tester, allowing for easy parameter setting and test execution.

-

Precision Control Systems: With PLC (Programmable Logic Controller) control, the tester provides precise regulation of temperature and timing, ensuring consistent and reproducible results.

-

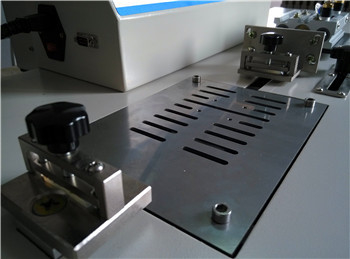

High-Quality Heating: The aluminum encapsulated sealing jaws of the Hot Tack and Seal Strength Tester ensure even heating, enhancing the accuracy of heat seal strength measurements.

-

Efficient Parameter Management: The tester allows for the storage and retrieval of multiple test parameter sets, streamlining the testing process and reducing setup time.

-

Adjustable Testing Speed: The Hot Tack and Seal Strength Tester offers adjustable testing speeds, accommodating various materials and testing requirements.

-

Safety Features: Includes auto zeroing, overload protection, and over-travel protection to safeguard the instrument and ensure accurate test outcomes.

-

Data Management Options: An RS 232 port is available for data transfer, and professional software is offered optionally for advanced data analysis and reporting.

Technical Specifications

- Sealing Temperature: Ambient to 250℃

- Temperature Accuracy: ±0.2℃

- Heat Seal Dwell Time: 0.1 to 9999 seconds

- Hot Tack Dwell Time: 0.1 to 9999 seconds

- Sealing Pressure: 0.15 MPa to 0.7 MPa

- Sealing Jaws: 50mm x 10mm Teflon Coated

- Heating Type: Double Heating

- Load Cell: 200N (Optional: 30N, 50N, 100N, 500N)

- Accuracy: 0.5 F.S.

- Resolution: 0.01N

- Stroke: 500mm

Standards Compliance

The Hot Tack and Seal Strength Tester adheres to the following industry standards:

- ASTM F1921

- ASTM F2029

- QB/T2358

- YBB 00122003

Applications of the Hot Tack and Seal Strength Tester

The Hot Tack and Seal Strength Tester is indispensable for industries where the quality of heat seals is critical. Key applications include:

- Packaging: Ensures the reliability of heat seals in various packaging materials to prevent leakage and ensure product protection.

- Food Industry: Verifies the strength of seals in food packaging to maintain freshness and safety.

- Medical: Tests the sealing integrity of medical device packaging to ensure sterility and efficacy.

- Beverage Industry: Assesses seal quality in beverage containers to prevent spoilage and ensure product integrity.

![]()