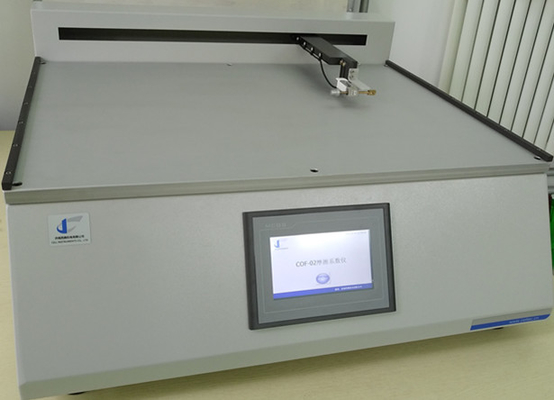

Textile Coefficient Of Friction Tester COF Testing Device

| Highlight | Textile,material test,fricion tester |

||

|---|---|---|---|

Textile Coefficient Of Friction Tester COF Testing Device

| Load Cell | 5 N(or as required) |

| Accuracy | 0.5 F.S. |

| Sled | 200±1g (or as required) |

| Sled Size | 63.5mm*63.5mm (or as required) |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) |

| Dimensions | 540mm(L)*380mm(W)*240mm(H) |

| Weight | NW 21kg |

| Power | 110~220V 50/60Hz |

![]()

![]()

The Textile Coefficient of Friction Tester is an essential instrument designed to accurately measure the static and kinetic coefficients of friction for a wide range of materials including plastic films, rubber, paper, and textiles. This advanced COF testing device is pivotal for industries such as packaging, food, medicine, and textiles, providing critical data to ensure material performance and quality.

Key Features

-

Precision Measurement: The Textile Coefficient of Friction Tester measures the frictional forces between different materials, allowing for the determination of both static and kinetic coefficients. This is crucial for applications where material interaction is vital.

-

Advanced Technology: Utilizing PLC control and a user-friendly touch screen interface, the tester offers real-time data display, enabling users to visualize test results and friction curves instantly.

-

Comprehensive Testing Capabilities: This device is capable of testing various materials such as PP woven bags, fabrics, metal-plastic composite belts for communication cables, and even brake pads. Its versatility makes it an invaluable tool in a laboratory setting.

-

International Standards Compliance: The Textile Coefficient of Friction Tester adheres to multiple international testing standards including ASTM D1894, ISO 8295, TAPPI T816, and GB 10006, ensuring reliable and comparable results across different materials and applications.

-

Data Management and Output: The system features RS232 output capabilities and professional software for detailed data analysis and reporting. Additionally, it includes microprint functionality for easy printing of test results.

Testing Principle

The testing process involves placing two samples in contact. A long strip sample is fixed on a flat surface while a squared sample is subjected to force via a sled. As the samples slip against one another, the friction force is meticulously measured, allowing for precise calculation of the coefficient of friction.

Applications

The Textile Coefficient of Friction Tester is ideal for a variety of applications, including:

- Testing the friction properties of textiles and fabrics.

- Evaluating the performance of packaging materials.

- Assessing the frictional behavior of medical device materials.

- Quality control in manufacturing processes involving rubber and plastic materials.

Why Choose Our Tester?

- Reliability: Built to deliver consistent and repeatable results.

- User-Friendly Design: The intuitive interface simplifies operation and reduces training time.

- Comprehensive Support: Backed by expert customer service to assist with any technical queries.

Conclusion

The Textile Coefficient of Friction Tester is not just a testing device; it's a gateway to ensuring quality and performance in materials used across diverse industries. By accurately measuring the frictional characteristics of textiles and other materials, businesses can enhance product development and maintain high standards of quality assurance.