Burst Tester Pressure Decay Burst Tester ASTM F2054 Open Pouch Burst Tester

| Warranty | 12 Months | Power | 110~220V |

|---|---|---|---|

| Highlight | burst,seal strength,creep to failure |

||

Burst Tester Pressure Decay Burst Tester ASTM F2054 Open Pouch Burst Tester

![]()

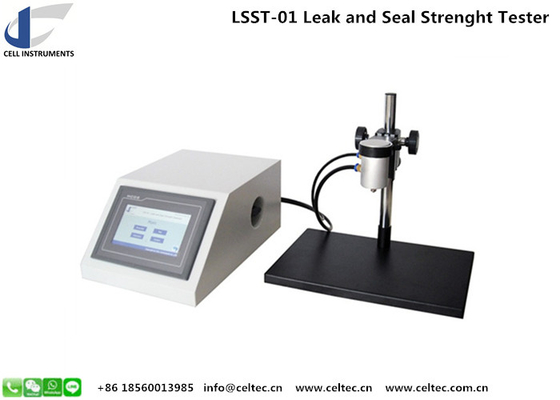

| LSST-01 Leak and Seal Strength Tester | |

| Test Range | 0~600KPa |

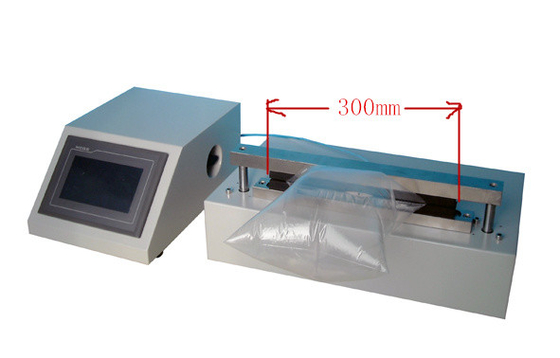

| Sample Width | 300mm (standard) |

| Inflating Head | Φ4mm |

| Compressed Air | 0.4~0.7MPa (Prepared by user) |

| Power | 110~220V 50/60Hz |

The Burst Tester is an advanced testing instrument designed for the quantitative determination of various physical properties of flexible and aseptic packages. It plays a crucial role in evaluating the sealing strength, heating sealing quality, burst pressure, and leakage of different packaging materials. Ideal for use in laboratories across industries such as packaging, food, medicine, and beverages, this device ensures that packages meet the required standards for durability and performance.

The Burst Tester is also instrumental in testing the sealing performance of pilfer-free bottle caps and soft tubes. It assesses parameters such as compression strength, the connection strength between the cap and body, cap losing strength, seal strength, and the butting strength of tubes. This comprehensive functionality makes it a versatile tool for various applications.

Burst Tester Pressure Decay Burst Tester Principle

The Burst Tester operates using three distinct test modes to evaluate package performance under pressure:

-

Burst Test: This mode internally pressurizes the package until it fails. The maximum pressure detected before failure is recorded as the burst pressure.

-

Creep Test: The package is pressurized to a specific level and maintained at that pressure for a defined period. The result is evaluated as pass or fail based on the package's ability to withstand the pressure.

-

Creep to Failure: In this mode, the package is subjected to a higher pressure than the creep test and held until it fails. The time until failure is measured, providing insights into the package's endurance.

Features of the Burst Tester

- Three Test Modes: The Burst Tester offers burst, creep, and creep to failure test modes for comprehensive analysis.

- PLC Programmable Logic Controller: Ensures precise pressure and time control, enhancing test accuracy.

- 7-Inch TFT Touch Screen: Facilitates easy parameter setting and test operation with a user-friendly interface.

- Multiple Test Parameters Storage: Saves multiple test parameters to avoid repetitive setting, improving efficiency.

- Auto Statistics and Storage: Automatically generates and stores test results for easy analysis and record-keeping.

- Dual Test Methods: Includes restraint distension and unrestraint distension methods for versatile testing.

- Program Customization: Allows for tailored test programs to meet specific requirements.

Technical Specifications

- Pressure Range: 0~600 KPa

- Beam Width: 300mm (for open packages)

- Inflating Head: Φ4mm (Standard for sealed packages)

- Gas Pressure: 0.4 MPa~0.9 MPa

- Port Size: Φ6 mm PU hose

Standards Compliance

The Burst Tester meets the following standards:

- ISO 11607-1

- ISO 11607-2

- ASTM F1140

- ASTM F2054

![]()