Heat Seal Property Tester for Film

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Highlight | seal property,tester,sealer |

||

|---|---|---|---|

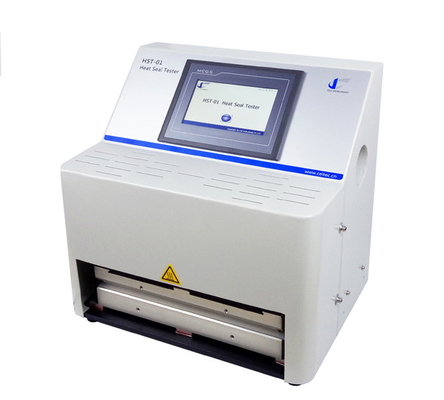

Heat Seal Property Tester for Film

| Sealing Temp. | Ambient~300℃ |

| Deviation | ±0.2℃ |

| Sealing Time | 0.1S~9999S |

| Sealing Pressure | 0.15~0.7 MPa |

| Seal Jaws | 330*10 mm L*W |

| Gas Pressure | 0.7 MPa |

| Port Size | Ф6 mm PU Hose |

| Power | AC 220V 50Hz |

The Heat Seal Property Tester is a cutting-edge instrument designed to help laboratories, manufacturers, and researchers accurately determine the ideal sealing parameters such as temperature, time, and pressure. This device is crucial in testing the heat sealability of various materials, including films, laminates, composites, and polymers. By optimizing the sealing process, the Heat Seal Property Tester ensures that packaging materials meet industry standards and deliver consistent sealing performance.

Why Choose the Heat Seal Property Tester?

The Heat Seal Property Tester is essential for any company involved in packaging or material testing across industries such as food, pharmaceuticals, beverages, and other consumer products. This tester provides precise data on how materials respond to heat sealing, enabling you to adjust your manufacturing processes for maximum efficiency. Whether you're working with flexible packaging, medical-grade materials, or industrial laminates, this tester will provide you with the insights you need to ensure product quality and reliability.

Key Features of the Heat Seal Property Tester

- Multiple Sealing Temperature Measurement: The Heat Seal Property Tester can measure up to five different sealing temperatures in a single test, making it highly efficient for testing a variety of materials at once.

- Precise Dwell Time and Pressure Control: Equipped with proximity and pressure sensors, the device ensures accurate control over sealing time and pressure, ensuring consistent results.

- P.I.D. Temperature Control: The tester uses Proportional-Integral-Derivative (P.I.D.) control, allowing for precise regulation of sealing temperatures, reducing temperature fluctuations that could compromise material integrity.

- Uniform Heating with Encapsulated Sealing Jaws: The aluminum-encapsulated sealing jaws provide uniform heating, preventing any uneven heat distribution that could lead to inconsistent seals.

- Customizable Sealing Jaws: The Heat Seal Property Tester allows for customization of the sealing jaws in terms of dimensions, shape, and surface, making it adaptable to a wide range of applications and materials.

- Independent Upper and Lower Jaw Heating: Both the upper and lower sealing jaws are independently heated, providing additional flexibility and control over the sealing process.

Comprehensive Applications Across Industries

The Heat Seal Property Tester is ideal for testing in various industries, including:

- Food Packaging: Ensuring proper sealing in food packaging is essential for product safety, shelf life, and consumer satisfaction. The tester helps determine optimal sealing parameters for food-grade films and laminates.

- Pharmaceutical Packaging: Medical and pharmaceutical products require precise packaging to maintain sterility and integrity. The Heat Seal Property Tester guarantees that seals meet stringent industry regulations.

- Beverage Packaging: Beverages need reliable seals to prevent leaks and contamination. This tester helps ensure that beverage containers are securely sealed during production.

- Industrial Laminates: For heavy-duty materials used in industrial applications, the tester provides crucial insights into the material's heat sealability, ensuring durability and performance.

Standards Compliance

The Heat Seal Property Tester is designed to comply with international standards, ensuring reliable and accurate testing results. Some of the standards met by the device include:

- ASTM F2029: This standard outlines the test method for evaluating the heat sealability of packaging materials.

- QB/T 2358: A Chinese standard specifying the technical requirements for heat seal testing.

- YBB 00122003: A standard applicable to medical packaging materials, ensuring that products meet regulatory requirements.

How the Heat Seal Property Tester Works

The Heat Seal Property Tester operates by simulating the actual sealing process in a controlled environment. By adjusting variables such as sealing temperature, dwell time, and pressure, the tester determines the material’s optimum heat sealability. This data can then be applied to real-world manufacturing conditions, allowing companies to optimize their production lines for efficiency, consistency, and quality.

The device uses independent heating systems for the upper and lower jaws, allowing users to apply varying temperatures to different surfaces, which is particularly useful for multi-layer materials like laminates and composites. This capability ensures that the sealing properties of each layer are tested and evaluated for overall performance.

Customization Options

One of the standout features of the Heat Seal Property Tester is its customizable sealing jaws. Depending on the material and application, users can select the dimensions, shape, and surface finish that best suit their testing needs. This adaptability makes it a versatile tool in any laboratory or production environment, catering to a wide range of materials and packaging configurations.

Advantages of Using the Heat Seal Property Tester

- Increased Efficiency: With the ability to measure multiple temperatures and sealing conditions in a single test, this device significantly reduces testing time while improving accuracy.

- Enhanced Quality Control: By determining the optimal sealing conditions for each material, manufacturers can reduce waste, improve packaging integrity, and ensure product safety.

- Versatility: The customizable sealing jaws and independent heating controls make this tester ideal for use with a wide variety of materials, from flexible films to rigid laminates.

- Compliance Assurance: Meeting industry standards like ASTM F2029 ensures that your products comply with regulatory requirements, helping you avoid costly recalls or compliance issues.

- User-Friendly Interface: The Heat Seal Property Tester features an intuitive interface that allows for easy setup and operation, reducing the learning curve and improving workflow efficiency.

Maintenance and Calibration

Regular maintenance and calibration of the Heat Seal Property Tester are recommended to ensure optimal performance and longevity. The device is built for durability, but routine checks on the heating elements, sensors, and sealing jaws will help maintain its precision and efficiency. Calibration should be performed according to industry standards to ensure consistent, reliable results.

Supplementary Equipment and Accessories

To maximize the functionality of the Heat Seal Property Tester, several accessories and supplementary equipment options are available. These include additional sets of sealing jaws for different material types, calibration kits, and advanced control software for more detailed analysis and reporting. These accessories can be customized based on specific testing needs, further enhancing the flexibility of the device.

Why Invest in a Heat Seal Property Tester?

Investing in a Heat Seal Property Tester can lead to significant long-term savings by improving product quality and reducing production inefficiencies. With the ability to test various materials in a controlled environment, you can prevent costly errors and ensure that your packaging meets or exceeds industry standards. This tester is an essential tool for any business involved in the production of packaging materials, ensuring that your products remain safe, secure, and compliant.

![]()

![]()