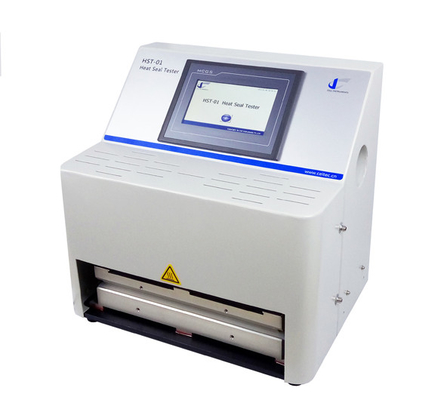

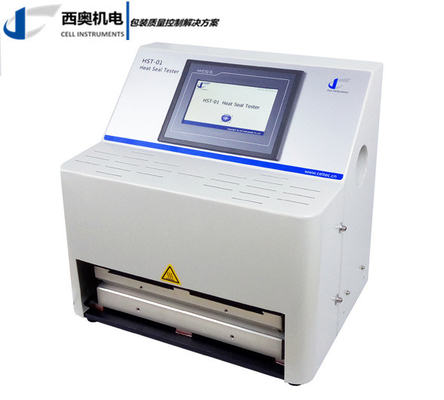

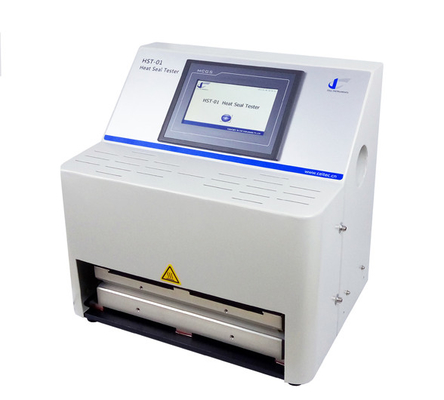

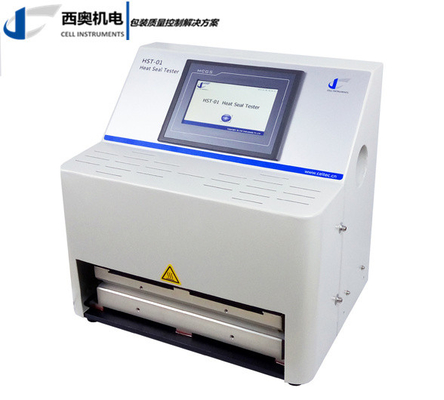

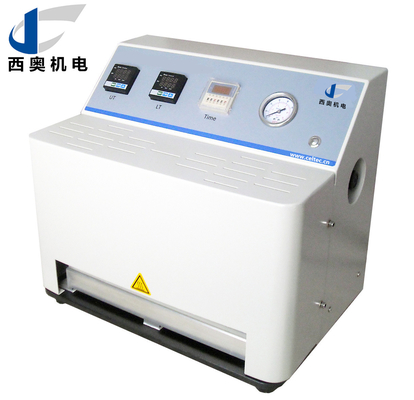

Seal Tester Plastic Film Heat Sealer Heat Sealing Parameter Tester

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Highlight | heatseal,material,plastic |

||

|---|---|---|---|

Seal Tester Plastic Film Heat Sealer Heat Sealing Parameter Tester

![]()

| Sealing Temp. | Ambient~300℃ |

| Deviation | ±0.2℃ |

| Sealing Time | 0.1S~9999S |

| Sealing Pressure | 0.15~0.7 MPa |

| Seal Jaws | 330*10 mm L*W |

| Gas Pressure | 0.7 MPa |

| Port Size | Ф6 mm PU Hose |

| Power | AC 220V 50Hz |

Seal Tester – Precise Heat Sealing for Plastic Films and Packaging Materials

The Seal Tester is an advanced heat sealing parameter tester designed for laboratory use in packaging, food, medicine, beverage, and industrial sectors. It simulates real-world sealing conditions, accurately determining the optimal sealing parameters, including temperature, time, and pressure. The Seal Tester is essential for ensuring the integrity and durability of plastic films, laminates, composites, and polymer-based packaging materials. By utilizing this instrument, manufacturers and researchers can optimize their sealing processes to meet industry standards, reduce material waste, and enhance product quality.

What is a Seal Tester?

A Seal Tester is a crucial device used to determine the heat sealability of packaging materials. It evaluates how well materials such as plastic films or laminates can be sealed under specific conditions, including heat, pressure, and dwell time. This process is vital in industries like food and pharmaceuticals, where secure packaging ensures product safety, prolongs shelf life, and prevents contamination. The Seal Tester provides accurate data to optimize these parameters and ensure that packaging meets strict regulatory standards.

Key Features of the Seal Tester

7-Inch TFT Touchscreen Display: The Seal Tester comes with a modern, intuitive touchscreen interface that allows operators to easily set and monitor test parameters such as temperature, pressure, and time. This ensures ease of use and enhances productivity in busy laboratory environments.

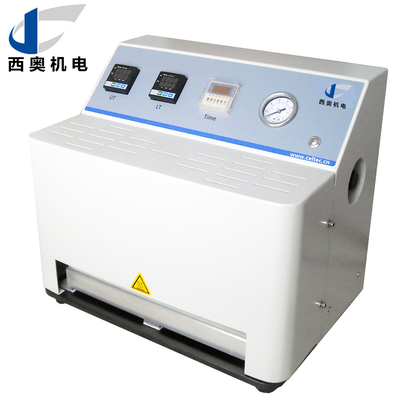

Precise Dwell Time and Sealing Pressure Control with PLC: The device features a programmable logic controller (PLC) to maintain accurate control over sealing time and pressure. This eliminates inconsistencies, ensuring repeatable and reliable test results.

P.I.D. Temperature Control System: Using Proportional-Integral-Derivative (P.I.D.) technology, the Seal Tester offers precise control over the sealing temperature, minimizing fluctuations that could compromise the integrity of the seal.

Uniform Heating Across Sealing Jaws: The aluminum-encapsulated sealing jaws ensure even distribution of heat, eliminating inhomogeneous heating that could lead to weak or failed seals.

Multiple Test Parameter Storage: Operators can save multiple groups of test parameters, reducing setup time and preventing human error during repetitive testing processes.

Independent Upper and Lower Jaw Heating: The Seal Tester allows for independent heating of the upper and lower sealing jaws, providing added flexibility for testing different materials or layered composites with unique heat requirements.

Customizable Sealing Jaws: The sealing jaws are fully customizable in terms of dimension, shape, and surface, allowing the Seal Tester to accommodate a wide variety of material types and test configurations.

Applications of the Seal Tester

1. Food Packaging

Food safety and shelf life are paramount in the packaging industry. The Seal Tester is widely used to determine the optimal heat sealing parameters for food-grade plastic films and laminates. Ensuring strong, uniform seals helps maintain the freshness and safety of food products while reducing the risk of contamination during transport and storage.

2. Pharmaceutical Packaging

Pharmaceutical packaging must meet stringent regulatory standards to ensure product safety. The Seal Tester is an essential tool for testing the heat sealability of medical-grade films, blister packs, and sterile barriers. It ensures that seals are strong enough to maintain the sterility and integrity of the product, preventing contamination and preserving efficacy.

3. Beverage Packaging

For beverage packaging, maintaining an airtight seal is critical to prevent leakage and preserve the quality of the product. The Seal Tester helps beverage manufacturers optimize the heat sealing parameters for pouches, bottles, and flexible containers, ensuring that seals are both reliable and durable.

4. Consumer Goods and Industrial Packaging

In industries such as electronics, cosmetics, and industrial goods, secure packaging is necessary to protect products from damage during shipping and handling. The Seal Tester helps companies ensure that packaging materials provide robust seals under various environmental conditions, reducing the risk of product returns or damage.

How Does the Seal Tester Work?

The Seal Tester works by applying controlled heat and pressure to a sample material for a set period of time. Operators can adjust the temperature, pressure, and dwell time to simulate the actual sealing process used in production. The Seal Tester measures the heat sealability of the material, ensuring that the resulting seals are strong, uniform, and capable of withstanding various environmental factors.

The device allows for independent control of the upper and lower jaws, making it ideal for testing multi-layer films or composite materials that require different heat applications. With its advanced P.I.D. temperature control and precise pressure sensors, the Seal Tester ensures that test results are accurate and reliable, reducing the risk of material waste and production downtime.

Technical Specifications of the Seal Tester

- Sealing Temperature: Room Temperature ~ 300°C

- Temperature Deviation: ±0.2°C

- Dwell Time: 0.1s ~ 9999s

- Sealing Pressure: 0.15 MPa ~ 0.7 MPa

- Sealing Jaws Dimensions: 330mm × 10mm (Customization Available)

- Independent Heating for Upper and Lower Jaws

- Gas Pressure: 0.7 MPa of Air

- Dimensions: 455mm (L) × 320mm (W) × 440mm (H)

- Port Size: Ф6 mm PU Hose

- Power Supply: AC 220V 50Hz

Standards Compliance

The Seal Tester complies with internationally recognized standards, ensuring that your testing processes meet the highest levels of industry best practices. These standards include:

- ASTM F2029: Standard Test Method for Heat Sealability of Flexible Barrier Materials.

- QB/T 2358: Chinese national standard for heat sealing performance testing.

- YBB 00122003: A regulatory standard used in medical packaging to ensure heat seal strength and integrity.

Advantages of Using the Seal Tester

- Increased Accuracy: The Seal Tester eliminates human error by providing precise control over sealing parameters, ensuring consistent and repeatable results.

- Faster Testing Process: The ability to save multiple test parameters and use pre-set configurations reduces setup time and accelerates the testing process.

- Versatility: The customizable sealing jaws and independent jaw heating systems make the Seal Tester adaptable to a wide variety of materials, from thin plastic films to complex multi-layer laminates.

- Improved Quality Control: With precise data on sealing temperature, pressure, and time, manufacturers can optimize their packaging processes, resulting in stronger seals and reduced product recalls.

- Regulatory Compliance: Meeting ASTM F2029 and other industry standards ensures that your products comply with regulatory requirements, reducing the risk of compliance issues or product failure.

Maintenance and Calibration

To ensure consistent performance, regular maintenance and calibration of the Seal Tester are recommended. This includes routine checks on the sealing jaws, heating elements, and pressure sensors. Calibration should be carried out according to industry standards to maintain accuracy and reliability over time.

Conclusion: The Importance of Seal Testing in Packaging

Packaging plays a critical role in product protection, and a reliable heat seal is a key component of effective packaging. The Seal Tester provides manufacturers with the data they need to optimize sealing parameters and ensure that their packaging materials meet the highest standards of quality. Whether you're in the food, pharmaceutical, or consumer goods industry, the Seal Tester is an invaluable tool for improving product safety, reducing waste, and ensuring regulatory compliance.![]()