Pendulum Impact Resistance Tester ASTM D3420 Pendulum Impact Tester

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xPendulum Impact Resistance Tester ASTM D3420 Pendulum Impact Tester

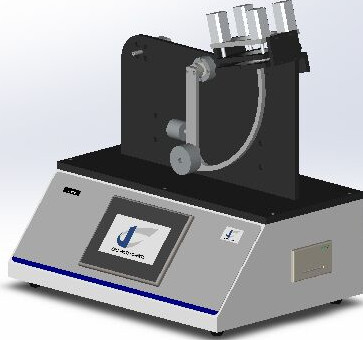

The Pendulum Impact Resistance Tester is a precision-engineered laboratory instrument designed for evaluating the impact resistance of thin materials such as films, foils, composite sheets, and packaging substrates. It performs standardized testing to measure the energy required to rupture a specimen by a free-swinging pendulum, conforming strictly to ASTM D3420, GB 8809, and NF T54-116 standards.

In quality control, material development, and research laboratories, the Pendulum Impact Resistance Tester plays a vital role in assessing how materials respond to sudden impact forces during transportation, processing, or end use. Understanding the dynamic strength of packaging or protective materials is crucial in sectors like food, beverage, pharmaceuticals, consumer goods, and industrial packaging.

![]()

Key Features of the Pendulum Impact Resistance Tester

-

Fully Automated Operation: PLC-controlled system with user-friendly touchscreen interface for intuitive test configuration and execution.

-

Consistent and Repeatable Results: Pneumatic clamping mechanism ensures consistent specimen holding. Automatic pendulum release guarantees uniform impact delivery.

-

Wide Testing Range: Configurable impact energy levels of 1 J, 2 J, and 3 J allow flexible application across various material strengths.

-

High Precision Measurement: Electronic sensing system with a resolution of 0.001 J provides accurate energy loss data for reliable analysis.

-

Flexible Fixture Configuration: Interchangeable impact heads (Φ25.4 mm, Φ19 mm, Φ12.7 mm) and clamp diameters (Φ89 mm, Φ60 mm) adapt to different material types and shapes.

-

Integrated Data Management: Real-time data acquisition, automatic statistics, and built-in microprinter streamline documentation and traceability.

-

Connectivity & Software: Optional RS232 interface and PC software integration for data export, analysis, and long-term record-keeping.

Applications of the Pendulum Impact Resistance Tester

The Pendulum Impact Resistance Tester is widely used in laboratories and industrial facilities that perform physical testing on packaging materials. The following industries regularly rely on pendulum impact data to optimize material selection and ensure compliance with quality assurance protocols:

-

Packaging Industry: Evaluate the toughness and burst resistance of flexible films, blister packs, and laminated pouches used in food and beverage packaging.

-

Pharmaceutical Sector: Test the integrity of packaging films and sachets used to contain medicines and medical devices.

-

Food and Beverage Manufacturers: Ensure packaging materials can withstand handling, shipping, and storage stress without compromising content safety.

-

Printing and Paper Industry: Assess the impact tolerance of coated and uncoated papers and specialized wraps.

-

Material Research & Academic Institutions: Develop and verify new film compositions or laminate structures with controlled impact absorption profiles.

Test Method and Standard Compliance

The Pendulum Impact Resistance Tester follows the protocol outlined in ASTM D3420, which specifies procedures to determine the impact resistance of plastic films by a free-falling pendulum. It measures the energy absorbed during rupture, helping to evaluate material toughness.

Additionally, the instrument supports testing according to GB 8809 and NF T54-116, providing global compliance and enabling its use in both domestic and international markets. Whether your operation must meet regulatory demands or internal quality benchmarks, this tester ensures results are standardized and repeatable.

Technical Specifications

| Parameter | Specification |

|---|---|

| Impact Energy | 1 J, 2 J, 3 J (Standard Configurations) |

| Resolution | 0.001 J |

| Impact Head Size | Φ25.4 mm, Φ19 mm, Φ12.7 mm (Customizable) |

| Clamp Diameter | Φ89 mm, Φ60 mm |

| Specimen Dimensions | 100 mm × 100 mm or Φ100 mm |

| Power Supply | AC 220V, 50 Hz |

| Air Supply Pressure | 0.6 MPa |

| Gas Port Size | Φ6 mm |

| Standards | ASTM D3420, NF T54-116, GB 8809 |

Why Choose Our Pendulum Impact Resistance Tester?

Choosing the right impact testing equipment is crucial for dependable quality control. Our Pendulum Impact Resistance Tester offers:

-

Reliable and Traceable Data: Electronic data logging and optional software integration ensure audit-ready records.

-

Custom Configuration: Modular design allows adjustment of energy range, clamp sizes, and impact head types based on your specific testing needs.

-

Exceptional Build Quality: Rugged construction suited for long-term use in laboratory and production environments.

-

Global Standards Compliance: Full compatibility with ASTM, GB, and European standards for universal acceptance of test results.

-

After-Sales Support: Comprehensive user training, calibration services, and prompt technical assistance.

Whether you are a packaging engineer, lab manager, or QA/QC specialist, this Pendulum Impact Resistance Tester is your essential tool for characterizing the toughness of critical materials.

Benefits for B2B Buyers

-

Increased Product Reliability: Identify material weaknesses early and improve packaging performance before market release.

-

Compliance Assurance: Simplify audits and certifications with testing aligned to international standards.

-

Reduced Claims and Returns: Improve package durability, minimize breakage during logistics, and enhance customer satisfaction.

-

Faster R&D Cycles: Accelerate new material development with fast, accurate testing results.

-

Investment in Precision: Achieve laboratory-grade performance and repeatability in routine QA workflows.

Custom Solutions Available

In addition to our standard models, we offer customized Pendulum Impact Resistance Testers tailored to specific requirements, such as unique sample sizes, extended energy ranges, or integration with laboratory information management systems (LIMS). Contact our engineering team to discuss your needs and get a tailored solution that fits your workflow.

Industries Served

-

Flexible Packaging Manufacturing

-

Medical and Pharmaceutical Packaging

-

Food and Beverage Processing

-

Academic and Research Institutions

-

Label and Coated Film Production

-

Industrial Materials R&D

Conclusion

The Pendulum Impact Resistance Tester is a cornerstone testing instrument for companies and laboratories concerned with material integrity under impact stress. From packaging validation to product development, it delivers precision, compliance, and long-term reliability.

If you're searching for a dependable solution to perform ASTM D3420-compliant impact resistance tests, our Pendulum Impact Resistance Tester offers unmatched value and performance.

![]()