Vacuum Air Leak Tester For Package Sealed Package Leak Tester PET PP Bottle Leak Tester PVC Barrel Leak Testing

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Standard | ASTM D3078 | Test Sample | Sealed Pack, Container Etc |

|---|---|---|---|

| Vacuum Range | 0~-90 KPa | Test Space | 270mm*210mm |

| Chamber | PMMA | Brand | Cell Instruments |

| Power | 110~220V |

Vacuum Air Leak Tester For Package Sealed Package Leak Tester PET PP Bottle Leak Tester PVC Barrel Leak Testing

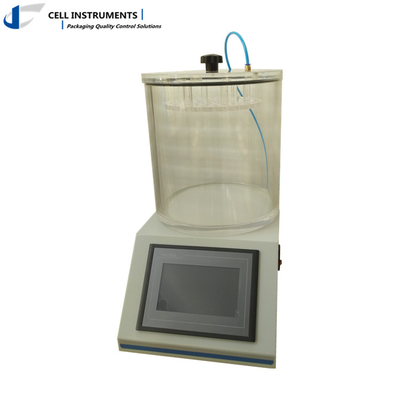

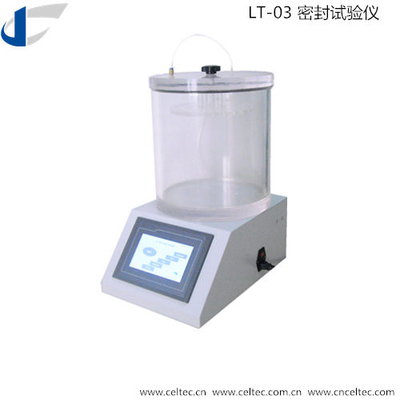

The Vacuum Air Leak Tester is a state-of-the-art testing instrument used to evaluate the airtightness and leak resistance of sealed packaging, containers, bags, and pipes. Ideal for use in various industries such as food, beverages, pharmaceuticals, daily chemicals, and electronics, this versatile tester ensures that your packaging meets the highest quality standards.

Why Choose the Vacuum Air Leak Tester?

The CELL INSTRUMENTS LT-03 Vacuum Air Leak Tester is engineered for precision and ease of use, offering reliable leak detection for PET, PP bottles, PVC barrels, and plastic bags. It’s the ideal solution for testing the integrity of sealed packages, helping businesses avoid costly product damage, contamination, and non-compliance issues. Designed for both small and large-scale testing, the vacuum air leak tester is widely used in industries such as:

- Food and Beverage Packaging

- Pharmaceutical Packaging

- Electronics

- Daily Chemicals

- Electrical and Electronic Components

- Packaging Manufacturers

| Test Range | 0~-90 KPa |

| Chamber | Acrylic Cylinder Shape |

| Test Space | Φ270*H210mm (Inside Usable) |

| Compressed Air | 0.7MPa (Prepared by user) |

| Power | 110~220V 50/60Hz |

This device meets ASTM D3078 and GB/T 15171 standards, ensuring that it is compliant with industry regulations for leak testing. It is highly regarded for its ability to detect even the smallest leaks in packaging, ensuring product safety and quality throughout the supply chain.

Key Features of the Vacuum Air Leak Tester:

Fully Automatic Testing Process: The Vacuum Air Leak Tester features a fully automated process, ensuring accurate and consistent results with minimal manual intervention. Simply load the package and let the tester perform the entire leak detection cycle.

Advanced HMI Touchscreen Interface: With a user-friendly touchscreen interface and PLC-controlled system, the tester allows for easy operation, real-time monitoring, and precise control over the testing process. The digital display shows the vacuum level and test duration, enabling efficient operation.

Customizable Vacuum Parameters: The vacuum degree and test time are easily adjustable to suit various package types and materials. This flexibility makes the Vacuum Air Leak Tester suitable for different industries and applications.

Automatic Data Storage: All test parameters and results are automatically saved for future reference. This ensures easy traceability and documentation of your testing process for quality assurance and compliance.

Vacuum Maintenance & Air Back-Flushing: The tester features automatic vacuum maintenance and air back-flushing capabilities, preventing air contamination and ensuring consistent performance over time.

Durable Vacuum Chamber: The Vacuum Air Leak Tester is equipped with a strong, corrosion-resistant vacuum chamber. It is designed for long-lasting durability and reliable performance under demanding conditions.

Custom Chamber Sizes: Different chamber sizes are available to accommodate various packaging types and sizes. Customization options make it suitable for specialized testing needs, whether for bottles, bags, or larger containers.

No Vacuum Pump Required: This testing device operates without the need for an external vacuum pump, simplifying setup and reducing maintenance costs.

Easy Operation and Low Maintenance: The Vacuum Air Leak Tester is designed for easy operation and minimal maintenance, reducing downtime and ensuring efficient operation in high-volume testing environments.

Technical Specifications of the Vacuum Air Leak Tester:

- Vacuum Level: 0 to -90KPa / 0 to -13PSI

- Vacuum Chamber Size: Φ270 mm x 210 mm (Height) (Customization available)

- Gas Source: Compressed air

- Gas Pressure: 0.7MPa / 101.5PSI

- Standards Compliance: ASTM D3078, GB/T 15171

Applications of the Vacuum Air Leak Tester:

- PET and PP Bottles: Effectively test the integrity of plastic bottles used in beverages, pharmaceuticals, and food packaging.

- PVC Barrels: Ideal for testing the airtightness of PVC barrels and other large containers used for chemicals and industrial materials.

- Plastic Bags: Widely used in the food and beverage industry to ensure the leak resistance of sealed plastic bags.

- Packaging Materials: Essential for packaging manufacturers to ensure that their products meet industry standards for leak resistance.

Standards and Compliance:

The Vacuum Air Leak Tester is built to comply with critical international standards, including ASTM D3078 and GB/T 15171. These standards ensure that the tester provides accurate and reliable results, helping you meet the strict requirements of various industries, such as pharmaceuticals and food safety.

Why Invest in the Vacuum Air Leak Tester?

The Vacuum Air Leak Tester is a critical investment for companies in industries where packaging integrity is paramount. By ensuring that your products are airtight and leak-free, you can avoid costly product recalls, improve customer satisfaction, and maintain regulatory compliance. Whether you're involved in food packaging, pharmaceutical packaging, or industrial testing, this tool will help streamline your quality control processes and enhance your operational efficiency.![]()

![]()