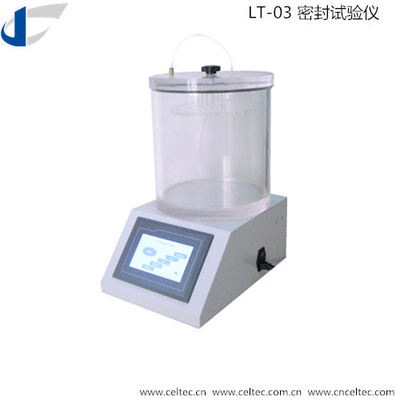

Package And Container Seal Integrity Testing Machine Leakage And Gross Leak Tester Astm D3078

| Standard | ASTM D3078 | Test Sample | Sealed Pack, Container Etc |

|---|---|---|---|

| Vacuum Range | 0~-90 KPa | Test Space | 270mm*210mm |

| Chamber | PMMA | Brand | Cell Instruments |

| Power | 110~220V |

Package And Container Seal Integrity Testing Machine Leakage And Gross Leak Tester Astm D3078

![]()

The Leak Tester for Package and Container Seal Integrity Testing is an essential device used to measure the airproof properties of various packaging materials, including containers, bags, pipes, and other sealed enclosures. This cutting-edge leak tester is designed for industries such as food and beverage, pharmaceuticals, daily chemicals, electronics, and more, ensuring that packaging maintains its integrity during storage and transportation. The device helps manufacturers ensure that their products are sealed properly, preventing leaks that could compromise product quality or safety.

Key Features of the Leak Tester

Our Leak Tester is engineered with advanced technology to provide accurate, reliable, and efficient testing for sealed packages. Below are some of the key features that make this machine stand out:

-

Automatic Leak Test Process

The leak testing process is fully automated, reducing the need for manual intervention and minimizing the risk of human error. The leak tester ensures consistent results across all tests, enhancing the reliability of your product quality control. -

User-Friendly Touchscreen Interface

Equipped with a modern human-computer interface, the leak tester features a user-friendly touchscreen for easy parameter setting and operation. This intuitive design ensures a smooth user experience, enabling even non-technical staff to operate the machine efficiently. -

Digital Vacuum Control

The leak tester uses precise digital controls for vacuum degree and test time input, ensuring the accuracy and repeatability of each test. The vacuum level can be adjusted from 0 to -90 kPa, allowing for highly customizable testing conditions suited to various packaging materials. -

Data Storage and Parameter Saving

With the leak tester, you can store different sets of parameters and test results. This function eliminates the need to re-enter data before every test and provides a history of results for future reference. This feature greatly reduces the chances of errors and improves operational efficiency. -

Automatic Vacuum Maintenance & Air Back-Flush

The leak tester is equipped with an automatic vacuum maintenance system that ensures a stable testing environment throughout the process. Additionally, the air back-flushing function helps to maintain the vacuum chamber’s cleanliness and ensures long-term performance without frequent maintenance. -

Durable Cast Vacuum Chamber

The leak tester features a robust cast vacuum chamber designed for durability and long service life. Its strong construction ensures that it can withstand the pressures of repeated testing, making it a reliable solution for high-demand testing environments. -

Flexible Chamber Sizes

The leak tester comes with a standard chamber size of 270 mm in diameter and 210 mm in height, with custom sizes available to accommodate different packaging formats. This flexibility ensures that the leak tester can be used for a wide range of packaging types, from small sachets to larger containers. -

No Vacuum Pump Required

Unlike many traditional leak testers, our model does not require an external vacuum pump. This feature simplifies the setup and reduces the overall maintenance costs associated with the device. -

Easy Maintenance & Operation

The leak tester is designed for ease of use and low maintenance. Its intuitive interface and automatic functions make it easy to integrate into existing production lines with minimal training.

Technical Specifications of the Leak Tester

| Test Range | 0~-90 KPa |

| Chamber | Acrylic Cylinder Shape |

| Test Space | Φ270*H210mm (Inside Usable) |

| Compressed Air | 0.7MPa (Prepared by user) |

| Power | 110~220V 50/60Hz |

- Compliance Standards:

-

- ASTM D3078

- GB/T 15171

Applications of the Leak Tester

This leak tester is widely used across a variety of industries to test the integrity of packages and containers. Some of the most common applications include:

- Food Packaging: Ensuring that food products are sealed properly to prevent spoilage and contamination.

- Beverage Containers: Verifying that beverage packaging is airtight and leakage-free, especially important for carbonated drinks and liquid food products.

- Pharmaceuticals: Testing for leaks in drug packaging to maintain product efficacy and safety.

- Daily Chemicals: Ensuring that chemical products are securely sealed to prevent leakage, especially for volatile substances.

- Electrical & Electronic Industries: Testing enclosures and sealed packages for moisture resistance and integrity.

Standards Compliance

The Leak Tester complies with international standards, ensuring that your testing procedures meet the highest quality benchmarks:

- ASTM D3078: Standard Test Method for Seal Integrity of Packaging

- GB/T 15171: National Standard for Leak Testing of Packaging Materials in China

Why Choose Our Leak Tester?

Choosing the right leak tester is crucial for maintaining product quality and compliance with industry standards. Our Leak Tester offers several advantages over other models:

- Reliability: Consistent, repeatable results with minimal human intervention.

- Cost-Effective: No need for a separate vacuum pump, lowering both upfront and long-term costs.

- Flexibility: Customizable chamber sizes and vacuum settings to meet the needs of different industries and product types.

- Efficiency: Automatic data storage, parameter saving, and easy maintenance ensure smooth operation without excessive downtime.

![]()

![]()

![]()

![]()

![]()